Structural carbon fibre research

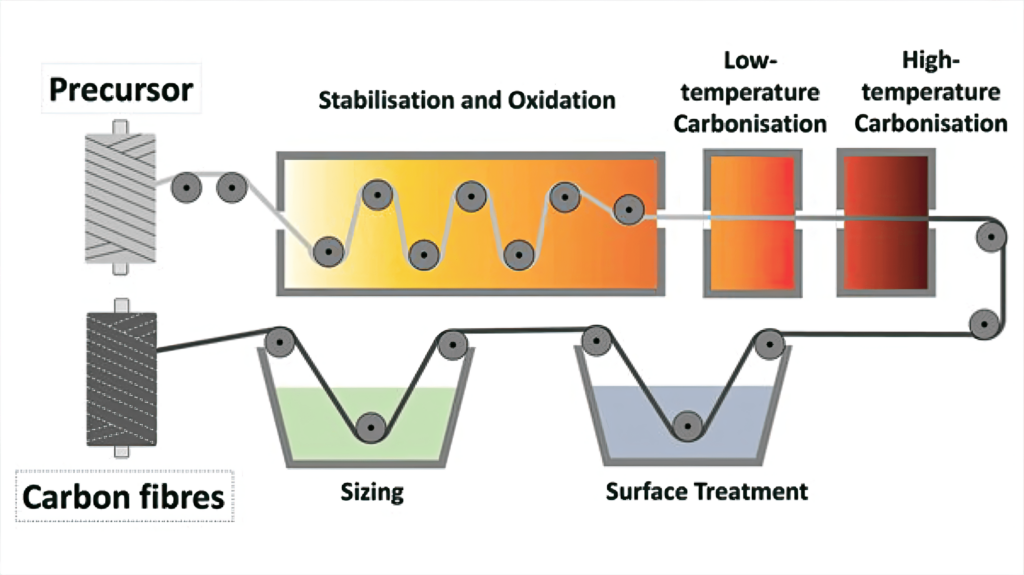

(Image courtesy of Chalmers University)

Researchers at Chalmers University in Sweden have shown how the manufacturing of carbon fibres can be tailored for developing structural batteries (writes Nick Flaherty).

They worked with Carbon Nexus at Deakin University, in Australia, to build a variety of fibres that are strong enough to use in vehicles but can also store significant amounts of energy.

However, the properties of the carbon fibre vary depending on the process parameters and which precursor is being used. Some types of carbon fibre can be very stiff, but have a far too low a storage capacity, and vice versa.

To be able to build efficient structural batteries, the carbon fibre needs to combine a sufficiently high electrochemical storage capacity with sufficiently good mechanical properties. The better the combined properties, the more efficient the battery.

How the manufacturing parameters affect carbon fibre’s mechanical properties is well-established, but relatively little has been determined around its electrochemical storage capacity. A key step in the development of structural batteries is to understand how the manufacturing process can be tuned to optimise the multi-functional properties of the carbon fibre.

The team explored the properties of carbon fibres made from the same precursor but with different tensions during processing. The research showed that fibres developed using both amorphous and crystalline phases of carbon affect the electrochemical capacity, as higher capacity is achieved by larger spacing in the fibres as well as higher void content.

ONLINE PARTNERS