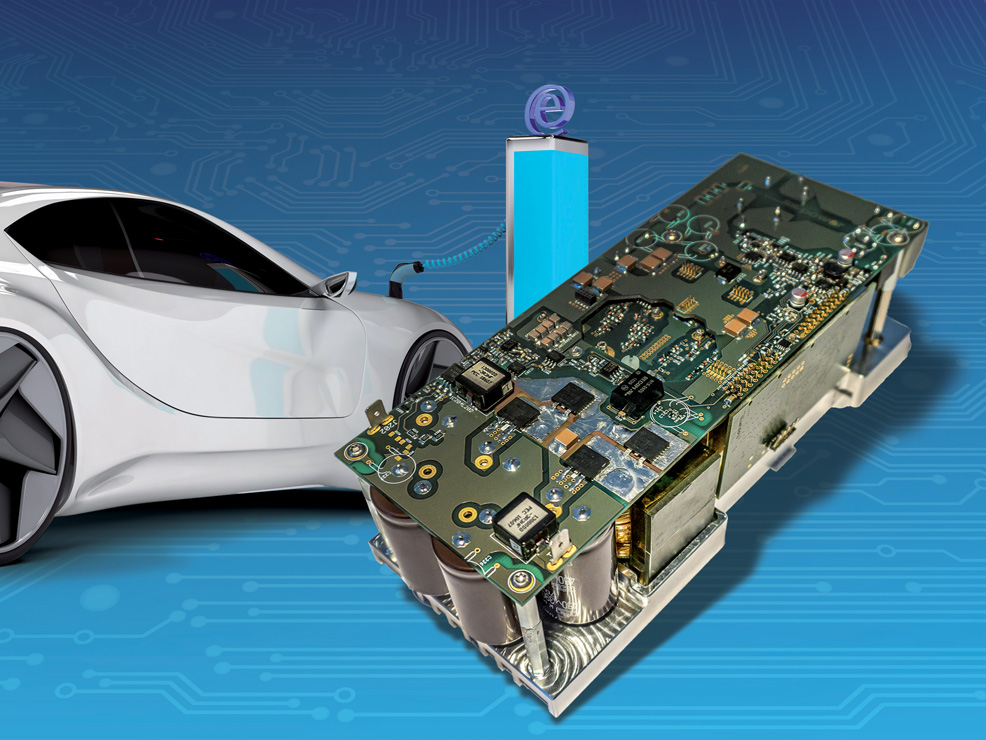

Onboard charger gives it 300%

Finepower has developed an onboard charger based on gallium nitride which, at 3 kW/litre, exceeds the power density of conventional chargers by 300% (writes Nick Flaherty).

The water-cooled charger measures 210 x 50 x 60 mm without the housing, and converts input voltages from 85 to 264 V AC, with a maximum power of 3600 W, to DC voltages from 200 to 450 V DC for 400 V battery packs. The maximum output current is 10 A.

The charger design uses a singlestage interleaved boost integrated (IBI) resonant topology with two inductors and a capacitor (LLC). It is a half-bridge topology that uses a resonant technique to reduce the switching losses due to zero voltage switching, even when there is no load, and also handles the power factor correction (PFC) that is usually in the first of a two-stage topology.

The topology scales up well to high power levels and has very low losses in devices that are on at all times, and is suitable for a wide range of input voltages. The downsides with it though are its complexity and cost.

In it, the PFC functionality is now implemented via two interleaved storage chokes, each of which is connected between a mains voltage input (phase or neutral) and one of two interleaved switching nodes. Galvanic isolation continues to take place via a transformer, which is part of a resonant circuit. There are further degrees of freedom regarding the secondary side, which can be designed passively with diodes or active synchronous rectification.

The design uses 650 V GaN top-cooled transistors that operate at switching frequencies from a few hundred hertz to several kilohertz. This higher frequency and the topside cooling allow the charger to be smaller, as the inductors and capacitors can be smaller than for designs using silicon IGBT transistors.

The switching nodes are implemented as interleaved half bridges that are 180º out of phase, with a special control structure that provides a smooth sinusoidal current. A microcontroller or digital signal processor with several pulse width modulation outputs is then used for directly controlling the respective driver circuits of the switching elements. That allows targeted load balancing between the interleaved half-bridges to improve the PFC and conversion efficiency.

The Finepower design has a power factor of 0.98, allowing 98% of the active power to be converted. At 230 V AC, that leads to an overall conversion efficiency of 97%, while the efficiency is 93% for 115 V AC.

Comms are via CAN bus, and up to three of the chargers can be coupled together for a three-phase supply, for example via three-phase sockets.

The charger is water-cooled, and operates from -40 to +60 C.

ONLINE PARTNERS