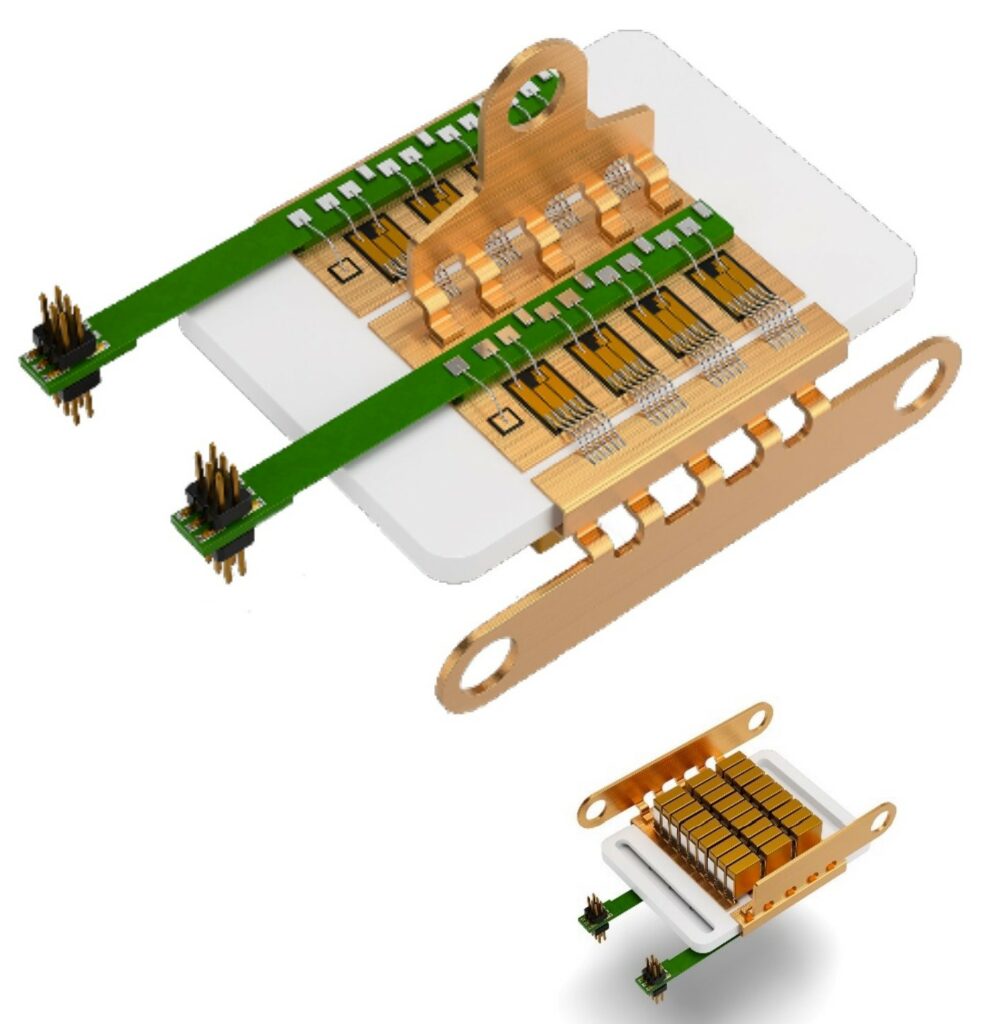

Double-sided ceramic power module for drive inverters

(Image courtesy of CeramTec)

Engineers in Germany have developed a double-sided ceramic power semiconductor module for more efficient cooling of silicon carbide (SiC) power devices in e-mobility designs (writes Nick Flaherty).

The ceramic module developed in the FuCera project dramatically cuts the size of drive inverters by providing more efficient cooling and allows vertical interconnection within the ceramic substrate as it is formed, further reducing the size and improving the electrical performance.

“This is a new concept,” said Hubert Rauh group manager, Advanced Power Modules, at Fraunhofer Integrated Systems and Device Technology (IISB) which has developed the module. “The classic module has the SiC devices on top with a ceramic substrate, but we now have new possibilities for building a power module using a ceramic cooler with integrated cooling.

“We have the possibility of using the rear side of the cooler for capacitors or terminals. We can have connections from the top to the bottom, or we can have wires going through the ceramic itself for rear-side metallisation. That offers us low inductance, as the capacitor is closer to the semiconductor devices.”

The engineers mounted the SiC power devices for a half-bridge converter directly on a substrate built with Alunit aluminium nitride ceramic developed by project partner CeramTec that has thermal properties of over 170 W/mK.

(Image courtesy of Fraunhofer IISB)

“The ceramic cooler is directly metallised so you don’t need interlayers, which means you can halve the thermal resistance,” said David Hassler, director, Product Management Industrial, at CeramTec. “This is a big advantage with better thermal performance, less weight and less space.”

Using a ceramic allows internal cooling structures to be built, for example as a pin-fin structure, and electrical connections can run on the outside of the substrate or be included in it. This would use connections through the pin fins that are not underneath the SiC devices.

Tested against a conventionally cooled single-sided substrate, the thermal resistance of the FuCera is halved.

The chip-on-heatsink design has also been applied to the new SiC power module with integrated ceramic cooler. The cooler consists of a liquid-flow aluminium nitride cooler with copper metallisation on both sides and an optimised pin-fin structure. The heat sink measures 48 x 36 mm with a thickness of 3.6 mm (including the metallisation) and a weight of 10 g.

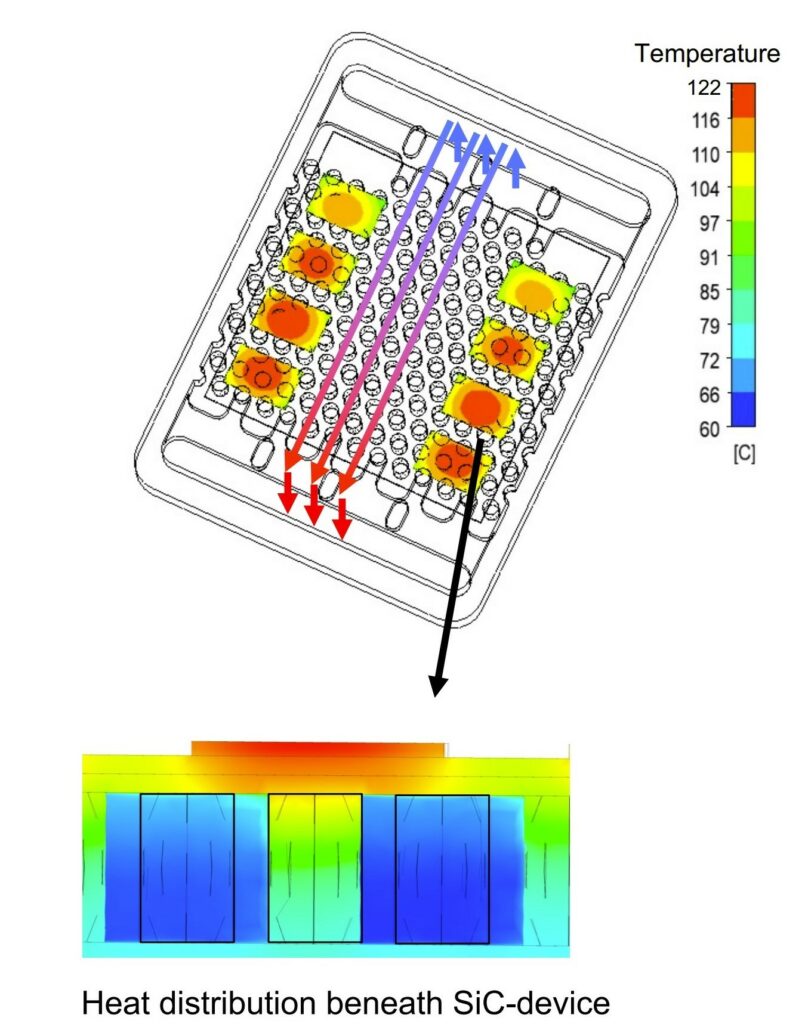

“The cooler weighs 60 g with a typical bottom plate, so this is a massive reduction in weight in the cooler itself,” said Rauh. “Mechanical stresses might be induced by a pressured sinter process, so we did lots of investigation on the structure beneath the chips, simulating the pressure working on the ceramic.

(Image courtesy of Fraunhofer IISB)

“All the chips have a very similar structure beneath them, so there is the same mechanical pressure during the 10 MPa pressure sintering process.”

“Pressures of 20 MPa are not problem for the ceramic cooler, and the contact of the metallisation is good from our shear tests,” he added.

The thermal resistance of the power module with pin-fin ceramic cooler is 0.15 K cm²/W from the chip to the cooling water. Using three modules in parallel for a typical drivetrain inverter design with a coolant flow of 7.5 litres/minute shows a pressure drop of 200 mbar, comparable to a conventional cooler.

“We have built up a very interesting power module based on CeramTec’s ceramic cooler technology, and we have shown we have a high thermal performance and low inductance for high switching performance,” said Rauh.

“We have built a prototype system with SiC devices using pressure-assisted sintering with bond wires at the top of the chip, and capacitors and DC and AC connections on the rear side. We are now planning other demonstrations and electrical tests of the performance.”

ONLINE PARTNERS