Dow unveils silicone rubbers for injection moulding

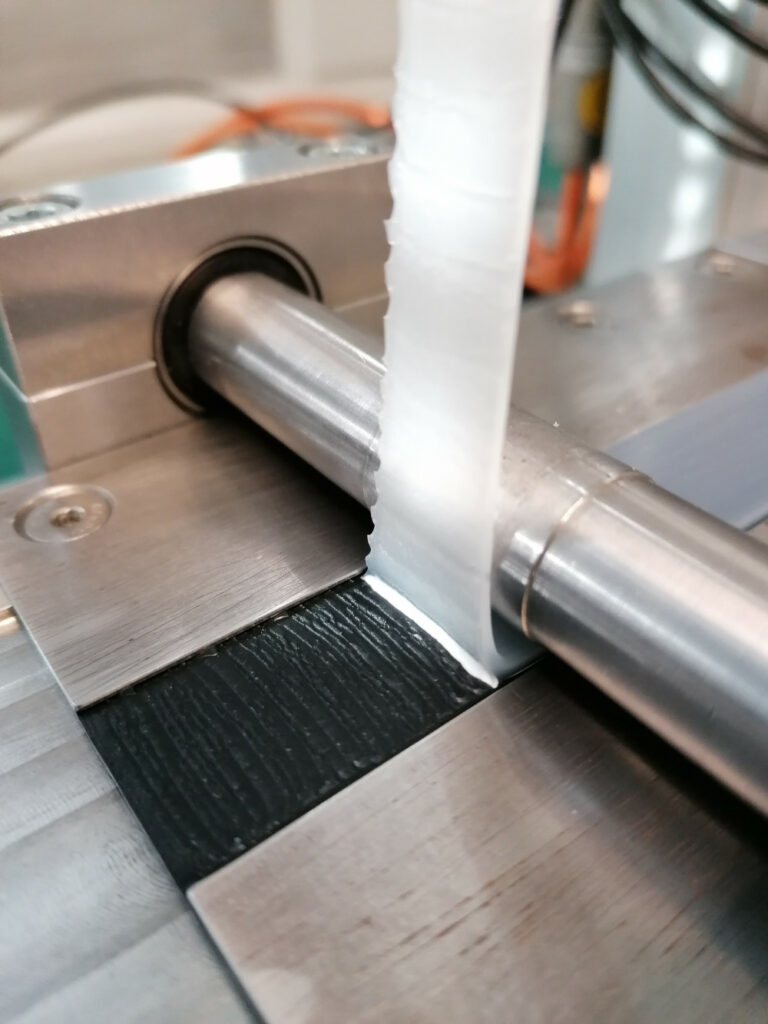

(Courtesy of Dow)

Dow has unveiled a new range of liquid silicone rubbers (LSRs) designed for two-component injection moulding with thermoplastic substrates including polybutylene terephthalate and polyamide.

Its Silastic SA 994X LSR series is a primerless, self-adhesive, general-purpose or self-lubricating, one-to-one mix ratio series of LSRs that can be used across multiple automotive applications such as connector seals, battery vent gaskets and radiator gasket seals for electric and hybrid vehicles, as well as environmental protection seals for the Lidar and radar housings in autonomous vehicles.

Their benefits include instant development of full bond strength to multiple plastic or metal substrates throughout their shelf life, without the need for further heat treatments, as well as adhesion durability in heat and humidity.

Patrick Beyer, senior research scientist at Dow, says, “The Silastic SA 994X LSR series is formulated to provide bonding to various engineering plastics in the automotive industry. Key physicochemical requirements for these adhesion promoters are fast diffusion and reactivity to the plastic interface, while allowing for covalent linkages into the LSR network.

“The adhesion promoter chemistry in the series has therefore been developed to provide for this required optimum balance of bulk and surface reactivity. Within the short production cycles of liquid injection moulding, full adhesive strength can be developed without further post-treatment.

“As a further result of this tailored reactivity, the Silastic SA 9940X LSR series shows an optimised shelf life of up to 12 months. The chemistry of these products has been developed to account for the various surface chemistries of common engineering plastics used in automotive applications, such as polyesters and polyamides.”

The SA 994X series is commercially available and comprises six products: SA 9940-30, SA 9940-40 and SA 9940-50 as general-purpose offerings, and a self-lubrication product range of SA 9942-30, SA 9942-40, and SA 9942-50.

“Because e-mobility in Europe is advancing far faster than many predicted, the speed of EV adoption and the continued and parallel developments in autonomous driving and ADAS capabilities are creating a need for new applications and new material combinations,” Beyer notes.

“With this new LSR series, connector seals, battery vent gaskets, radiator gaskets and sensor environmental protection systems can be produced using 2K injection moulding, allowing the production of integrated seals with a high degree of automation and process efficiency versus individual assembly.

“And since the series is designed to provide strong and instant adhesion to a wide range of substrates in automotive applications, different organisations can better adapt to these evolving market and material needs.”

ONLINE PARTNERS