ZF unveils modular EV drive platform boosting efficiency and cutting weight

(Image courtesy of ZF)

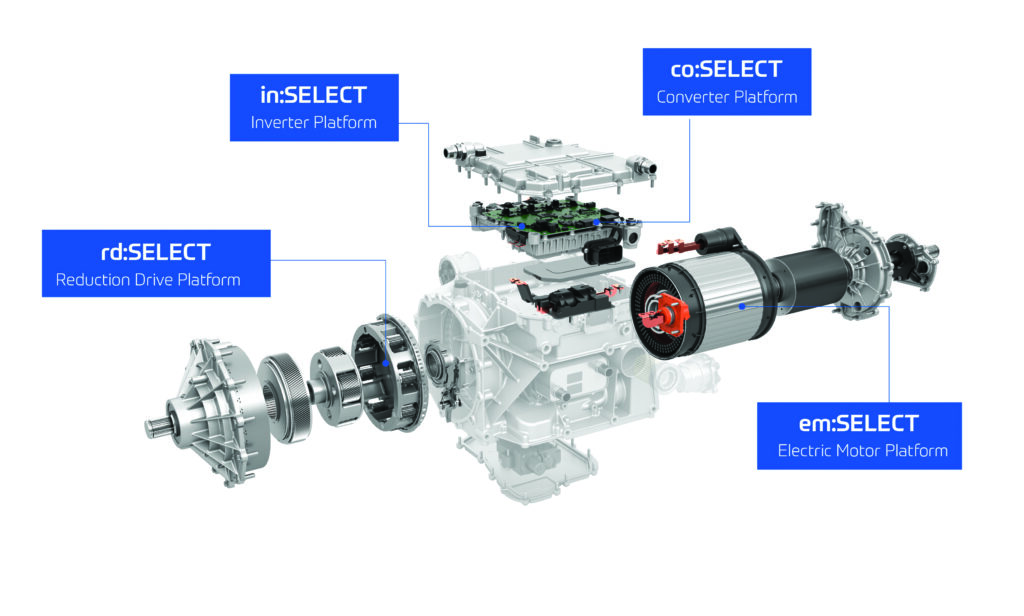

ZF has developed a modular drive system for EVs that boosts efficiency and reduces size, writes Nick Flaherty. The SELECT platform covers electric motors and transmission to the inverter and AI-enhanced control software. “If you just optimise one piece you miss out on the global optimisation and you have lower efficiency,” says Dr Otmar Scharrer, senior vice president R&D, electrified powertrain technology at ZF. “SELECT is the result of that optimisation. It’s a platform with four parts. The reducer is the transmission, which you definitely need in an EV as the motor runs faster than the wheels, and that needs a ratio of between 1:10 and 1:12. Then, we have the electric machine, the motor and the inverter and the software that is the brains of the system.”

The em:SELECT electric motor platform covers proven Permanently Excited Synchronous Machines and Asynchronous Machines through to new concept Separately Excited Synchronous Machines, which do not need magnets using rare earth elements (REEs), avoiding supply chain issues with REEs from China. This platform achieves 93% efficiency with peak power from 150 to 300 kW and torque from 3500 to 5500 Nm. Volume is reduced by 19% to 66 L and weight cut by 15% to 89 kg compared to the latest systems.

The 300 kW in:SELECT inverter supports both 800 V and 400 V systems. “The idea of the in:SELECT was to develop a very scalable and modular platform, with variations suitable for different e-motor packaging,” says Matthias Zechmann, product manager for the inverter platform. It uses both SiC and IGBT technologies within the same module, optimized with AI for liquid cooling variants ranging from aluminium coolers for 400 V IGBT to copper coolers with optimized fin structures for high-end 800 V vehicles.

The standard two-level inverter module is 4–5 cm thick and includes DC link capacitor and EMC filter, with the control and gate driver board produced on a sub-assembly production line. Variants are designed to be flexible for commercial vehicles as well as off-road and construction applications. “We might separate out the control and driver board in the future but currently it is not necessary,” says Zechmann.

Finally, the sw:SELECT software uses two cores – one for application software and another for drivers with dedicated customer interfaces. “We do not change the base core but change parameters and use predefined interfaces to communicate with customer systems. There is a lot of AI in the software,” says Scharrer. A key feature is temperature management; AI estimates maximum temperatures on the hottest drivetrain spots, allowing operation safely closer to limits without derating the system unnecessarily.

Click here to read the latest issue of E-Mobility Engineering.

ONLINE PARTNERS