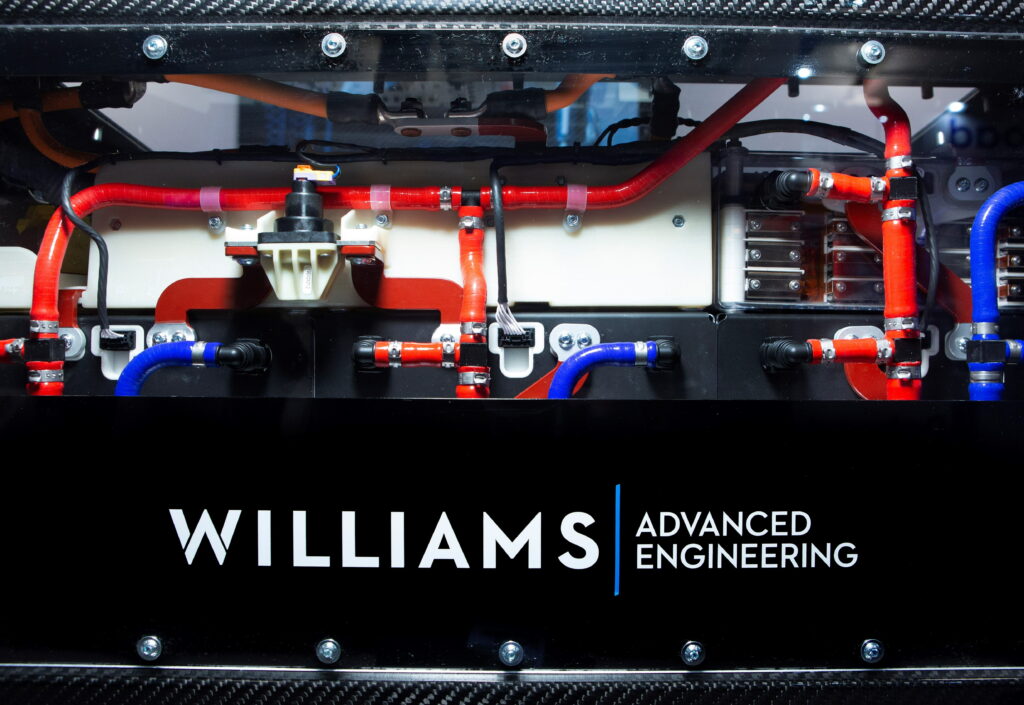

Williams Advanced Engineering and Molicell team up for high-power battery applications

(Courtesy of WAE)

In mid-August, Williams Advanced Engineering (WAE) and Molicell announced a strategic collaboration centred on lithium-ion batteries optimised for power density rather than energy density, and with applications in sectors including automotive and mining, as senior commercial manager for battery technology at WAE James Hoxey explains to Peter Donaldson.

“Our strategic collaboration enables us to focus on what we both do best,” he says. “Molicell explained to us why the cells are designed the way they are from a component perspective, and also talked openly about the chemistry. We in turn shared our design considerations, such as thermal management.

“The technical goal is to optimise our designs, better understand their cell design and enable Molicell to optimise what they are doing.”

In general, the requirements for cells optimised for power density are quite different from those optimised for energy density, with a strong emphasis on minimising internal resistance to increase power output.

WAE provides batteries for competitions including Formula E and Extreme E, and is looking to transfer the technology to high-performance road vehicles. In mining, the company is working on the electrification of vehicle fleets including giant haul trucks.

“While motorsport generally need 60 kWh battery packs on average, you are looking at 1-2 MWh of stored energy in an electrified mining haul truck. Both are power-optimised applications but they are used in very different ways,” Hoxey says.

Molicell’s power-optimised 18650 and 21700 format cylindrical cells provide discharge rates greater than 10C, but the company is targeting charge rates of 3-4C. Such high rates inevitably mean a lot of heat is dissipated, and thermal management is an important focus of the two companies’ collaboration. WAE has extensive experience of thermal management including serpentine, base and immersive cooling techniques.

Hoxey explains that they are working with Molicell engineers as they design the ‘can’ in order to optimise the cooling. “We are using an iterative process to work out whether we want to use a serpentine method because of the way the cell is managed, or whether an alternative solution would be more appropriate,” he says.

Immersive cooling is an attractive option for high-power applications, he adds, and has been used in Formula One kinetic energy recovery system packs for some time. He contrasts that with the battery WAE developed for the Extreme E off-road racing series.

“We didn’t even liquid-cool those because we were trying to build the ultimate rugged battery,” he says. “In an environment where there’s going to be a lot of abuse you need to take as much complexity out of the system as possible.”

(Courtesy of Molicell)

In the quest for the best blend of power density and energy density in batteries, WAE is developing its adaptive multi-chemistry approach, in which battery packs are built up from combinations of power-optimised and energy-optimised cells, both of which Molicell offers.

Compared with alternatives that use ultracapacitors, Hoxey explains, adaptive multi-chemistry technology provides more power over a longer power discharge time in the target applications, particularly in megawatt-scale mining vehicles. Here, the mixing and matching is done at a pack level rather than modules, he says.

“We build a number of 120 kW/h battery systems and then connect them. With eight of these blocks, six can be energy-dense and two power-dense. There is greater scalability in the multi-chemistry approach,” he says.

“The benefits of using ultracapacitors in combination with energy cells are also quite compelling in certain applications, just not those we are currently working on.”

ONLINE PARTNERS