Wheel motor test platform

Nissan has developed a test vehicle to evaluate the use of electric motors on each wheel (writes Nick Flaherty).

It is based on the Leaf e+ platform, with front and rear motors and what Nissan calls a new chassis control system. New control technology being developed by the company integrates its electric propulsion and four-wheeldrive control technologies with the chassis control technology, which monitors the motors.

Using separate front and rear EM57 electric motors, the powertrain generates up 227 kW and up to 680 Nm of torque.

Nissan said pitch and dive during changes in acceleration are minimised by adding regenerative rear-motor braking to that which is usually on the front motors.

When slowing down on city streets, for example, that helps keep passengers from being shaken around, reducing the potential for motion sickness and related discomfort. Similarly, on rough or bumpy roads and when accelerating, motor control is optimised to maintain ride comfort by minimising irregular movement.

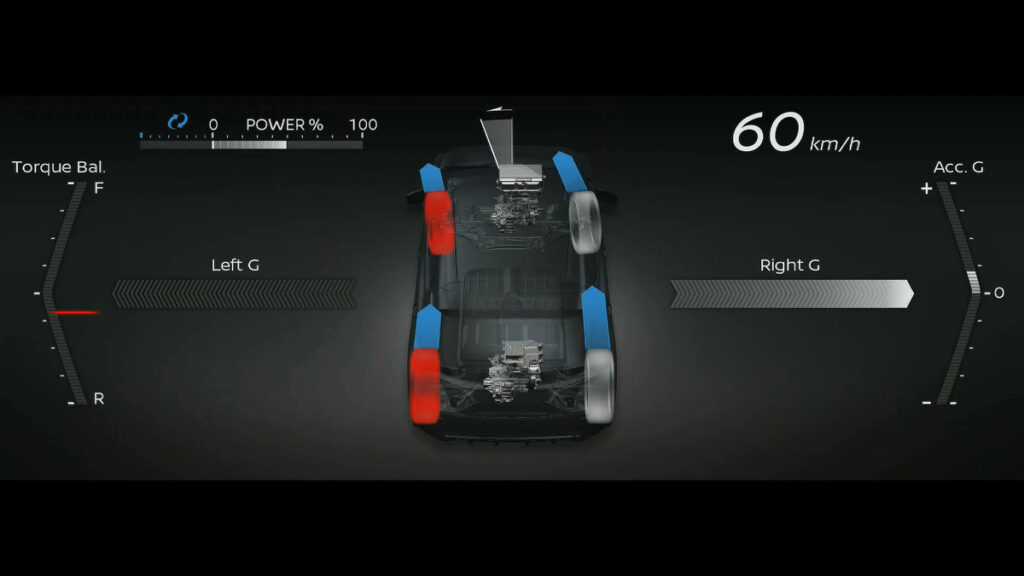

As well as optimising the front-rear torque allocation, the chassis control system applies independent brake control at each of the four wheels to maximise the cornering forces generated by each tyre, and helps with steering. This varies depending on how the car is being driven, including acceleration and braking on winding roads or a motorway, and can help provide the driver with a more optimal line through a turn.

The test vehicle has a 12.3 in display mounted in the centre of the instrument panel that provides real-time data from the chassis control module to help engineers understand the vehicle’s movement.

ONLINE PARTNERS