Vibracoustic develops battery pack isolator for large EVs

(Courtesy of Vibracoustic)

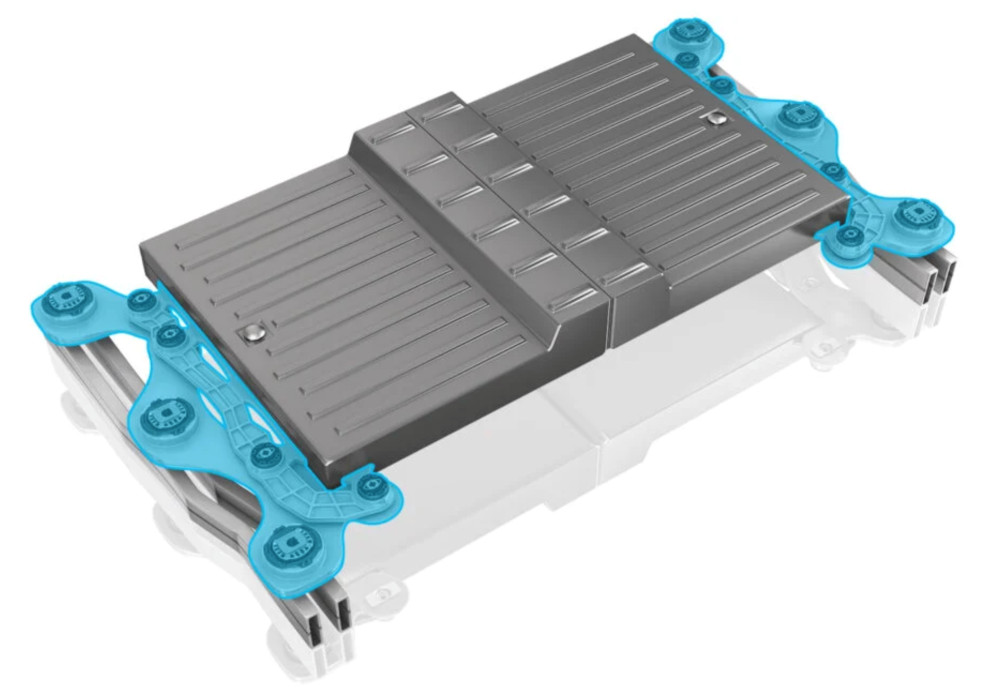

NVH solutions supplier Vibracoustic has developed a battery pack isolation system for body-on-frame vehicles such as pick-ups, off-road vehicles, large SUVs and light commercial vehicles.

The company says the system addresses some of the challenges with heavy battery packs in these vehicle classes. Unlike most existing unibody battery EVs, larger vehicles tend to use body-on-frame (body-on-chassis) designs, and the battery is often their most expensive component, so protecting it from unwanted loads and vibrations is a critical NVH objective.

One of the primary concerns with body-on-frame vehicles are the torsional bending forces in the chassis. While this can deliver advantages for factors such as manufacturing simplicity and off-road performance, a rigidly mounted battery pack can be subject to potentially damaging torsional loads. Beyond the safety implications, there is also passenger comfort to consider.

To address these issues, the Vibracoustic system uses multiple mounts consisting of a stamped steel housing, elastomer dampers and an extruded aluminium core. Each unit has been designed for peak loads of 50-60 kN, such as those experienced when driving over a pothole. The number of mounting points can be increased for larger battery packs, and the current design can cope with all common battery packs normally weighing between 500 and 800 kg.

The system has already been used in OEM hybrid applications and is now available globally.

ONLINE PARTNERS