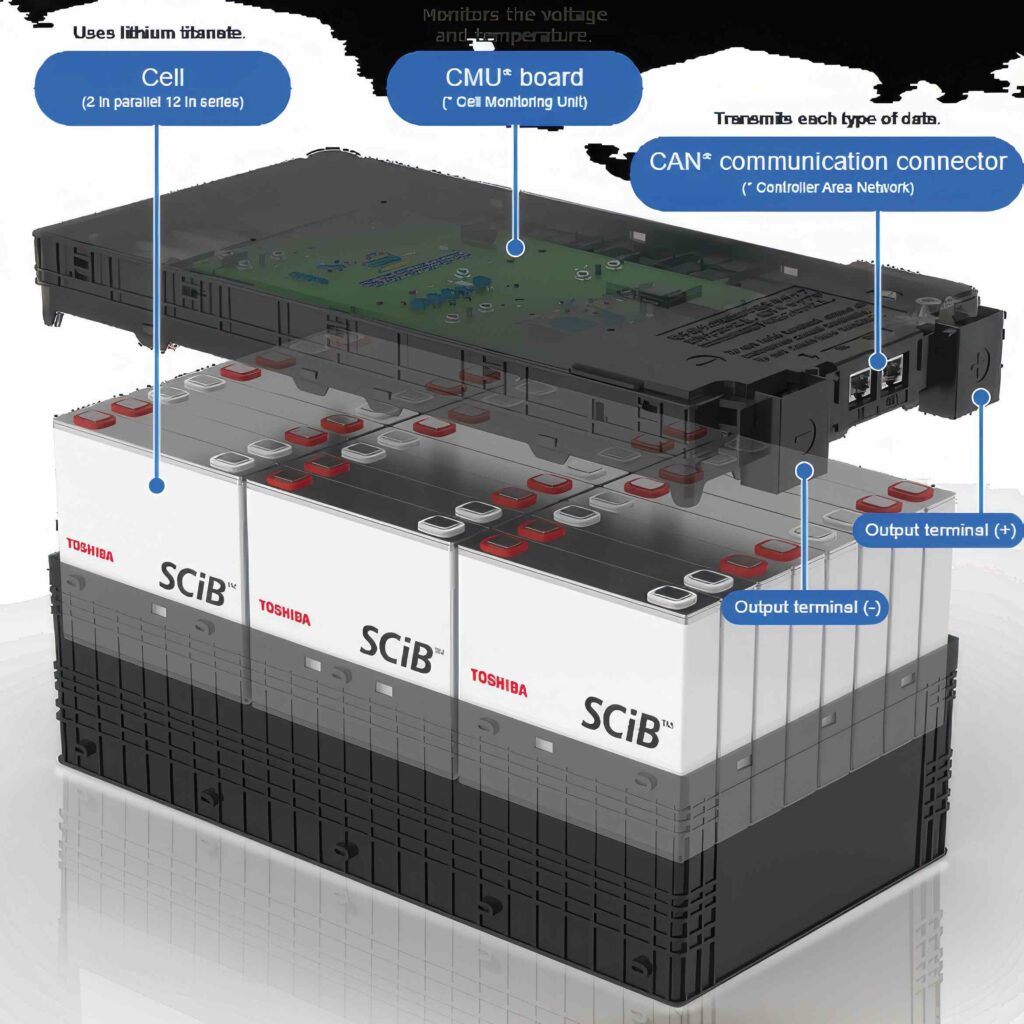

Next generation SCiB module for heavy duty designs

(Image courtesy of Toshiba)

Toshiba has developed a new version of its SCiB battery module for electric buses and ships, writes Nick Flaherty.

The new version uses an aluminium baseplate that dissipates approximately twice the heat of current modules for higher power applications.

Aluminium has lower thermal resistance than the resin materials usually used in the Toshiba module baseplates. However, because it is a conductor, the baseplate must be insulated from the battery cells.

Toshiba has developed a novel structure that achieves the required voltage resistance. When used with the same cooling system normally applied by vehicle makers, the heat dissipation is approximately double that of current modules, significantly extending battery life.

Constant input and output at high power levels in a short period generates life-shortening heat within batteries. This challenges battery developers to manage heat dissipation and maintain battery life with high power input and output over short periods.

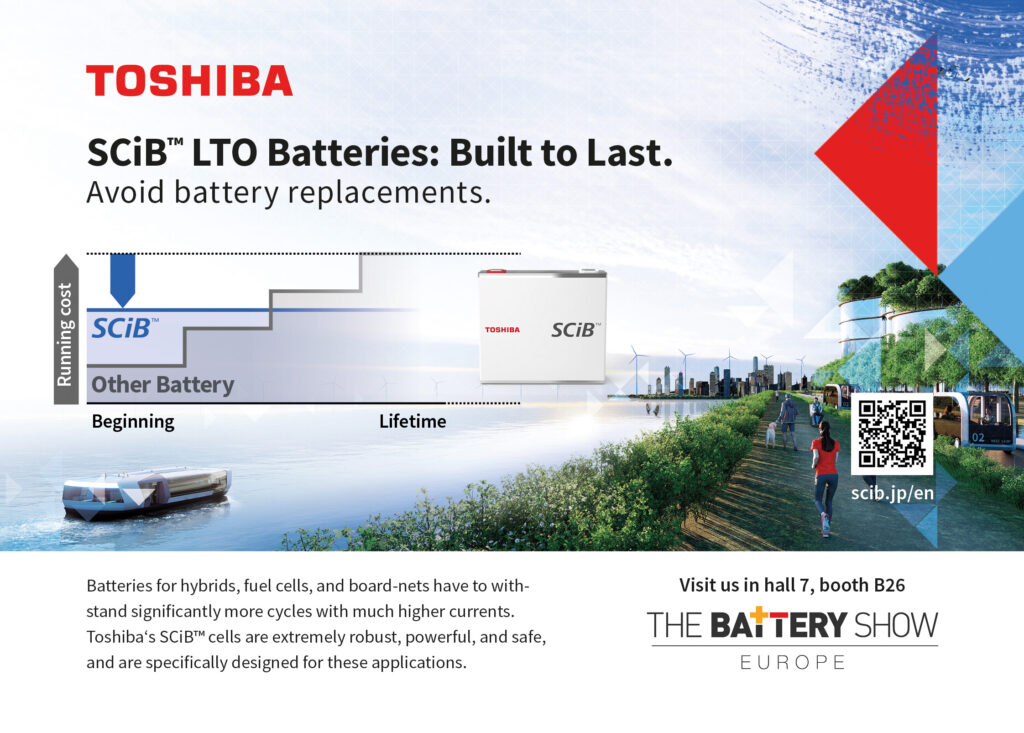

The SCiB cells have a lithium titanate negative electrode for safe operation and low-temperature performance from −30 to 50 C. This also allows fast charging in 6 minutes to 80% of capacity and a 100% effective state of charge, and a 20,000 cycle lifetime that means the cells are widely used in hybrid vehicles.

Users of module products want a balance between constant high input and output of 160 A continuous and 350 A for 30 seconds with long battery life. The Type4-23 module is the first to feature an aluminium baseplate for heat dissipation with two parallel strings of 12 x 23 Ah cells in series to provide 45 Ah. This gives a nominal voltage of 27.6 V for energy of 1.242 kWh in the 16.5 kg module.

Click here to read the latest issue of E-Mobility Engineering.

ONLINE PARTNERS