High-efficiency inverter

Pre-Switch has developed a 200 kW inverter architecture that achieves more than 99% efficiency with silicon carbide (SiC) transistors (writes Nick Flaherty).

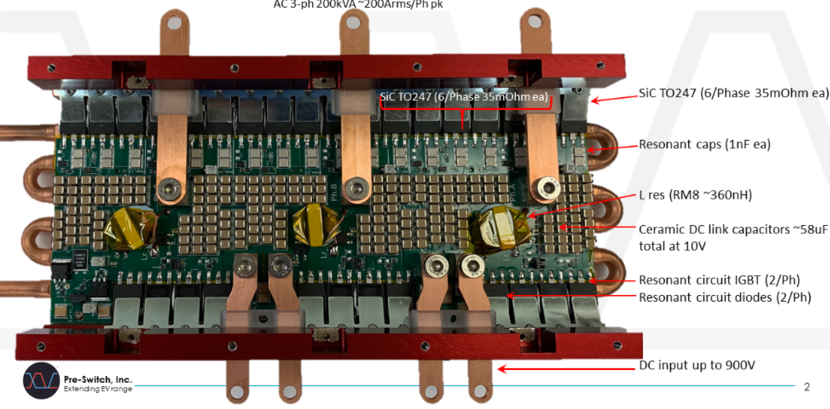

The 100 kHz CleanWave200 evaluation inverter uses three discrete, low-cost 35 mΩ SiC MOSFETs from UnitedSiC per switch location, and is of particular interest for electric aircraft.

The architecture uses a machine learning algorithm to constantly predict the zero-voltage switching point. This reduces the switching losses, increasing the efficiency, and significantly reduces the cost of the SiC MOSFETs required.

Pre-Switch’s algorithm analyses multiple inputs on a cycle-by-cycle basis, making adjustments in real time to small, forced-resonant transistors to enable perfect soft switching in harsh and changing environments. Variations in system temperature, device degradation, changing input voltages and abrupt current swings are all accounted for and optimised in the algorithm.

The machine learning predicts the zero-voltage, zero-current point to minimise switching losses. At 100 kHz the switching window is 100 ns, but the algorithm calculates the optimum 2 ns time slot, which can change with time and the condition of the switches.

“We use AI because we are taking a lot of data that’s incomplete in a noisy environment and calculate where the switching will be,” said Bruce Renouard, CEO of Pre-Switch. “We monitor the device temperature and switching speeds, and measure how the FET reacts and degrades over time, so we change the algorithm to compensate for that. We do some pattern matching but we are not using a look-up table; we calculate the responses for each transistor on a cycle-by-cycle basis.”

Pre-Switch has published data on the system efficiency for 50-100 kHz switching speeds, input voltages, power output and current output, enabling system designers to compare the Pre-Switch results for designs such as electric EVs.

The company is shipping the CleanWave200 to initial customers around the world for EV and electric aircraft designs.

“Switching losses using our technology are effectively zero,” said Renouard. “If we put that into perspective, an EV with Pre-Switch technology improves inverter efficiencies, producing a pure sine wave output that dramatically improves motor efficiency at low torques, where people drive much of the time. This will result in an increase in range of up to 12%.”

ONLINE PARTNERS