StoreDot announces eXtreme approach to charging

(Images courtesy of StoreDot)

StoreDot is developing new a lithium-ion battery technology it calls eXtreme Fast Charging (XFC) that will enable an EV to charge in 5-10 minutes (writes Peter Donaldson).

At the heart of it is a silicon-dominated anode that can accept lithium ions much faster than a graphite anode (thanks to silicon’s lower resistance) but controls the tendency of silicon to swell when it accepts those ions that would otherwise generate damaging mechanical forces inside the battery, the company’s CEO Doron Myersdorf says.

The Israeli start-up is backed investors Samsung, Daimler, BP and TDK, has raised about $130 million in capital, owns around 100 patents and has 35 PhDs in its team of 120 people, with specialisms in areas including materials science, organic chemistry and electrochemistry.

Myersdorf says this number of PhDs provides a level of research power equivalent to two faculties at the Massachusetts Institute of Technology, all focused on the problem of how to charge a battery quickly.

Established lithium-ion battery chemistry relies on graphite’s ability to store large numbers of lithium ions in an ordered manner within a lattice structure of the anode, to build up charge in the cell.

However, graphite’s high resistance makes this process too slow to support very high charging rates. If the charge rate is too high it causes metallisation, plating or the formation of dendrites, which Myersdorf says are simply different terms for the same basic problem.

“You cannot push in many of these ions very quickly because they start to build up at the entrance into the graphite lattice,” he says. “And with the high pressure and heat you get lithium metal dendrites. They are like nails – they puncture holes through the separator, create shorts and can trigger a chain of explosions.”

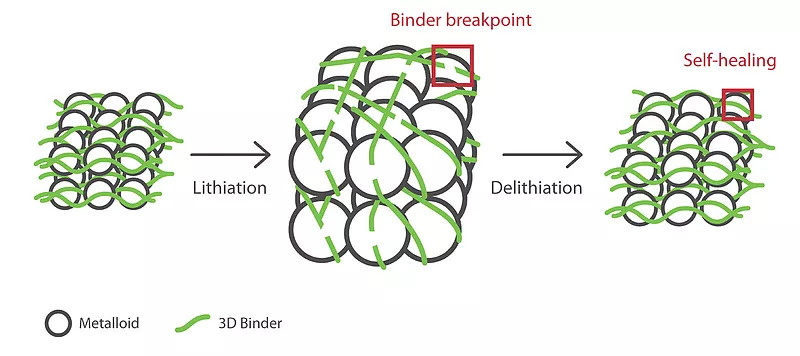

Using silicon in the anode avoids this problem but brings other issues. “Number one is that it expands like a balloon, around 300%, when you insert the ion,” Myersdorf explains. “So building a host matrix that holds the silicon in place and doesn’t allow it to expand too much is the key to fast charging.”

StoreDot’s solution is to use nanoscale silicon particles, which provide much more surface area to hold lithium ions and protect the silicon particles by coating them with organic compounds that create a stable matrix to limit the swelling. Getting this formulation right is very complex, Myersdorf says, so the company uses AI.

“There are many permutations and possibilities for factors such as the size of the particles, the kinds of additives to use and how much pressure to apply, all of which affect whether the formulation will be successful. AI and machine learning help us find the optimal formulation,” he explains.

StoreDot has demonstrated the XFC technology in a UAV, a phone and a scooter, and has developed both cylindrical and pouch cells, so Myersdorf is confident that it works.

“We are shipping 30 Ah cells in a form factor suitable for vehicles,” he adds. “These are pouch cells, but we are also demonstrating the technology in cylindrical cells such as the 4680 from Tesla, and other formats,” he says. “Now the question is how to scale it up, how to take it into a factory with our joint venture with EVE Energy in China for example, and how to make sure it will be repeatable, high quality and cost-effective.”

ONLINE PARTNERS