Standard pack for trucks unveiled

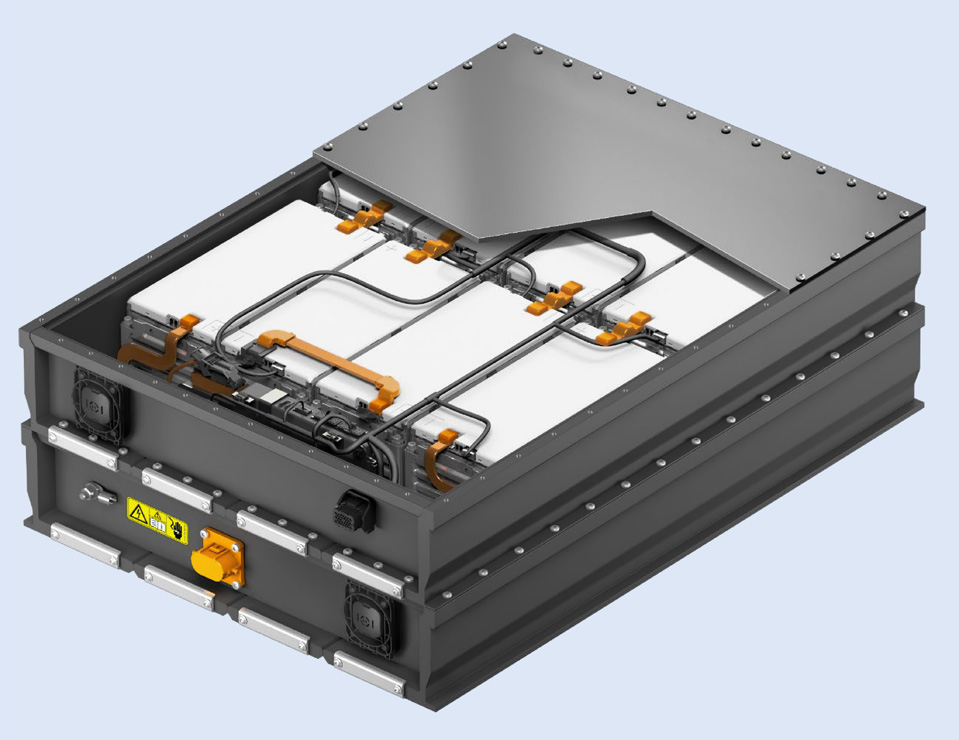

Webasto, better known for producing heating and cooling systems, has developed a standardised, modular battery pack for commercial EVs (writes Nick Flaherty).

The basic 35 kW, 400 V pack in the CV Standard Battery System has been designed to be used in series or parallel to support 800 V requirements. It uses NMC prismatic lithium-ion cells, and the company has also developed a modular BMS and software.

“We looked at the different requirements of buses and trucks to make the system as common as possible,” said Manuel Kagelmann at Webasto.

“It was necessary to design the hardware for the 800 V dielectric strength to meet the higher voltage, and we wanted to make it compatible with future infrastructure and software. For example, the market expectation is to be able to charge a vehicle quickly, which needs to be anticipated with DC charging.

“In the beginning we looked at third-party suppliers for the BMSs but after a while we decided to build our own. We had taken over a software and hardware company so we were able to develop and produce them ourselves.”

A primary vehicle interface box (VIB) controls secondary BMS units in each battery module, balancing the current flow from each one.

“If you connect more battery packs you can use higher rates as we route the control through the VIB, which acts as master BMS as one interface to the vehicle with the connector for DC charging and a power distribution unit. Using this can increase the charge and discharge rate,” Kagelmann said.

An 800 V system would use two or four packs for trucks with up to 100 kW. Putting up to 10 packs together provides 300 kW of power with a peak of 460 kW.

Cooling is a key issue at 800 V, so the modules use aluminium cooling plates on the bottom of each of two layers of packs inside the modules. That avoids having to use liquid cooling within the pack so there is no risk of coolant leaking.

“A lot of battery pack manufacturers put the thermal management inside, and with a leakage there is the risk that the cells are harmed,” he said. “We need thermal management but we want to keep it outside.”

“You need to connect external thermal management from the vehicle manufacturer though, and there we specify the pressure and temperature but we also offer a standard product, the electric battery thermal management system, which we designed for our batteries.”

ONLINE PARTNERS