Silver Power Systems and partners develop ‘world’s most advanced’ battery digital twin

Predicting the future performance and eventual longevity of a battery is something of a holy grail for the EV industry, the quest for which involves the creation of digital twins for batteries (writes Peter Donaldson). An established concept in other areas of industry, a digital twin is a high-fidelity software model of a real system to which it is linked in as close to real time as possible.

(Images courtesy of SPS)

With that goal in mind, EV battery analytics specialist Silver Power Systems (SPS) has partnered with Imperial College London and vehicle manufacturers London EV Company (LEVC) and JSCA (the r&d division of the Watt Electric Vehicle Company) on the recently completed Real-Time Electrical Digital Twin Operating Platform (REDTOP) project.

REDTOP has resulted in what is said to be the world’s most advanced battery digital twin, one that can predict battery lifetime.

SPS’ programme manager Liam Mifsud says, “To really understand a battery’s state of health and predict its future performance you need to know its history, how it has been charged and discharged and so on.”

Funded in part by the UK government’s Advanced Propulsion Centre, REDTOP combined SPS’ battery analytics expertise and Imperial’s modelling knowhow with operational data from a fleet of 50 hybrid taxis and two developmental electric sportscars from LEVC and JSCA respectively. Together, these vehicles provided more than 600,000 km worth of data over 9 months.

On the face of it, a little over 11,000 km per vehicle on average might seem a shaky basis for predicting a battery’s complete lifespan, but that is not what is happening.

“We are not just extrapolating from 10,000 km,” Mifsud says. “We are using the data to improve our models. We are developing these digital twins and algorithms that predict performance, and using the data to inform both.”

Mifsud emphasises that the knowledge gained from 52 vehicles with different histories and driven in different ways has allowed SPS to build up a normalised model of the relationship between battery performance and variables such as the way the vehicles are charged, the temperatures they are operated at, and the distances covered between charges. “The data informs the models, and the models do the prediction,” he says.

Although REDTOP is complete, SPS is arranging with LEVC to continue gathering data. “If we get three years of data from a vehicle fleet it’s going to be hugely beneficial for refining the models,” Mifsud says.

The taxis are hybrids with petrol range extenders that charge their batteries, which are liquid-cooled units from LG Chem with a wide range of install dates, ages and mileages. The sportscars meanwhile are pure EVs powered by air-cooled Nissan Leaf batteries.

While the taxi data fed into REDTOP reflected revenue service on the road, the sportscars were mostly put through their paces on test tracks, so the resulting diversity in the data was very useful for building the models, Mifsud notes.

With the taxis, SPS gathered most of the data it needed from the BMS through the CAN bus, adding only a GPS-equipped telematics unit and an accelerometer system. On one of the sportscars, however, in addition to gathering cell-level data from the BMS, it also installed a parallel set of temperature sensors for comparison purposes.

This data was fed into models created by Imperial College. While it is possible to model batteries as ‘black boxes’ by taking only the inputs and outputs into account, Imperial built physics-based models informed by an understanding of the battery’s electrochemical make-up to mimic what happens in individual cells in terms of temperature and current during charging and discharging.

The data is used to parametrise the model. “In this phase, you look at the real data from the battery and adjust the parameters of the model so that it actually represents the battery,” Mifsud explains.

“The next phase is validation, where you run the digital twin model and compare its outputs with what you get from a real drive cycle. We are doing that now in our labs with the models that Imperial created.”

While every battery in REDTOP had its own digital twin, the plan going forward is to create twins of categories of batteries defined by make, model and how they are operated. In future, automating the model-building, parametrisation and validation using AI would enable the creation of digital twins for individual batteries, Mifsud says.

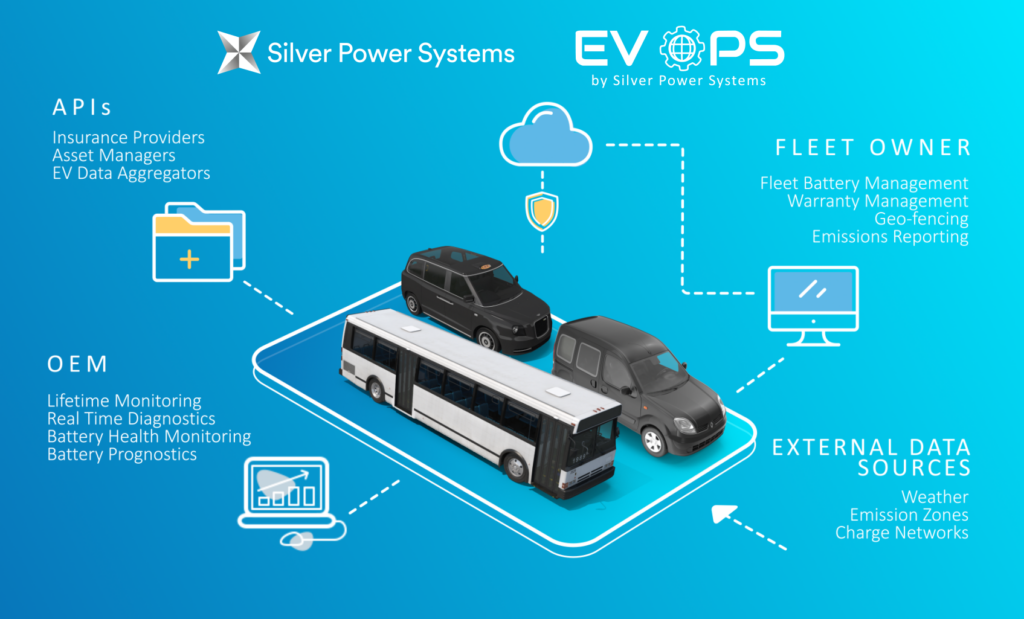

SPS is now offering digital twins as a service, using a web-based platform called EVOPs, through which fleet operators can monitor their vehicles’ batteries, as well as working on other services for insurance companies and local traffic authorities for example.

ONLINE PARTNERS