Scania introduces industrial batteries for off‑road electrification

(Image courtesy of Scania)

Scania has broadened its electrification portfolio with the establishment of Scania Industrial Batteries, a new division focused specifically on industrial and off‑road machinery. Based in Sweden, the organisation builds on Scania’s acquisition of Northvolt Systems’ Industrial Division earlier this year and is tasked with delivering complete electrified powertrain solutions for applications such as mining, construction and material handling.

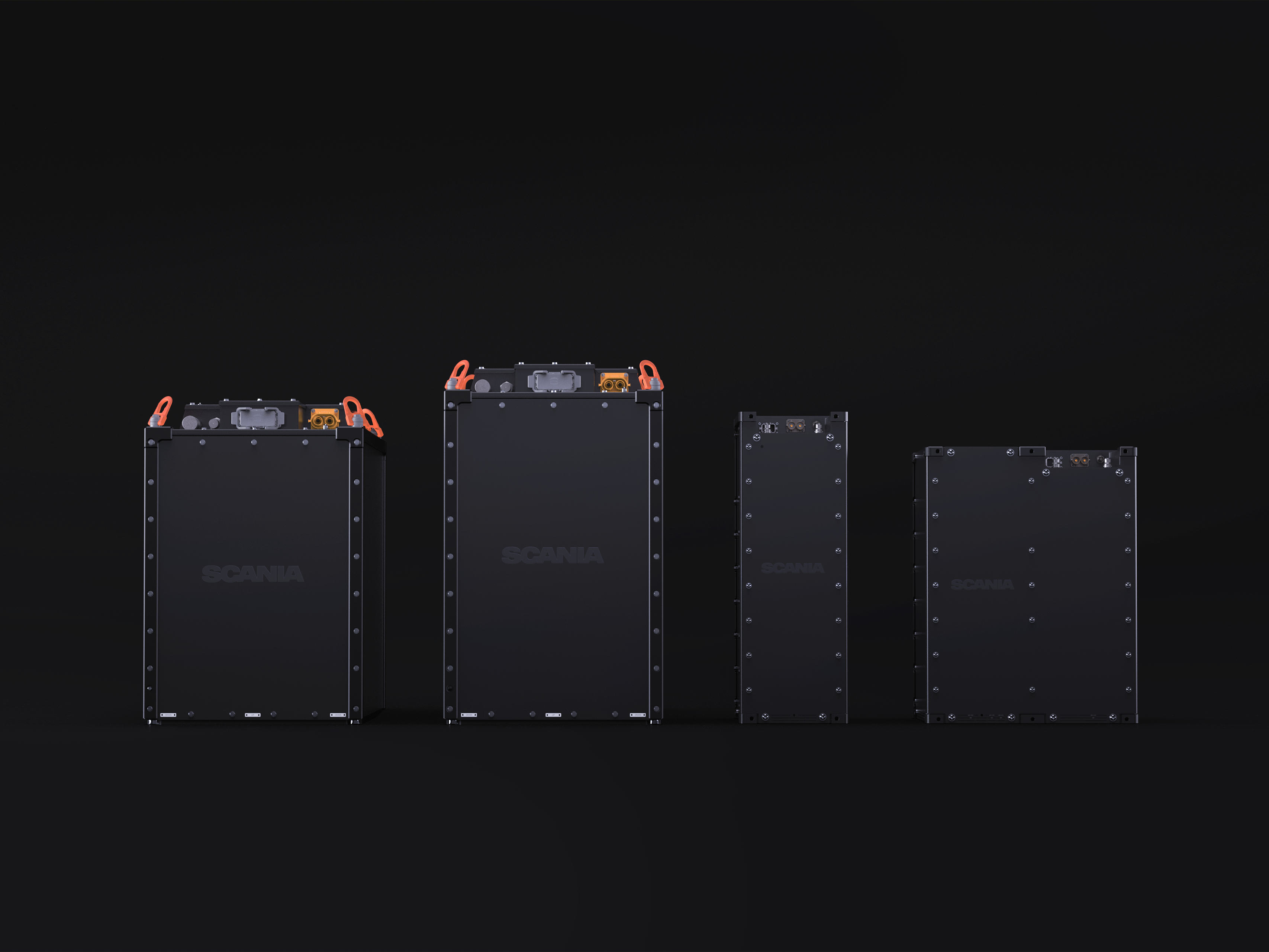

The division’s first products are two modular battery platforms, Core and Compact, offering capacities from 21 to 624 kWh and system voltages up to 1000 V. These are available either as stand‑alone packs or as part of a complete electric powertrain, together with motors, power electronics, control software, connectivity and service architecture. Manufacturing is carried out at a facility in Gdańsk, Poland, with R&D centred in Stockholm.

The move reflects the accelerating electrification of off‑road machinery, where high energy consumption and demanding duty cycles make the benefits of electrified drivetrains particularly valuable. Energy cost reductions and the potential for substantial emissions savings are driving uptake in heavy industries that operate under the most challenging environmental and thermal conditions. Designing battery systems for such use requires high levels of engineering optimisation to meet requirements for durability, thermal management, efficiency and uptime, alongside precise integration within existing machine platforms.

According to Scania, the new division has already accumulated more than seven years of operational data, with thousands of battery systems deployed and over 12 million hours of accumulated field use in mining, construction and agricultural equipment. The focus has been on modular, compact units that integrate efficiently across different machine platforms while meeting the load demands of intensive cycles such as excavation, hauling and material handling.

The company states that by consolidating battery system design with electric motors and associated power electronics it can deliver optimised powertrains tailored for industrial end users and equipment OEMs. The capability to supply a fully engineered electrification package is intended to simplify the transition from combustion engines to electric systems while supporting efficient deployment and lifetime performance in sectors where machine downtime or operational inefficiency can carry major cost penalties.

Click here to read the latest issue of E-Mobility Engineering.

ONLINE PARTNERS