SABIC cube cells pack more energy

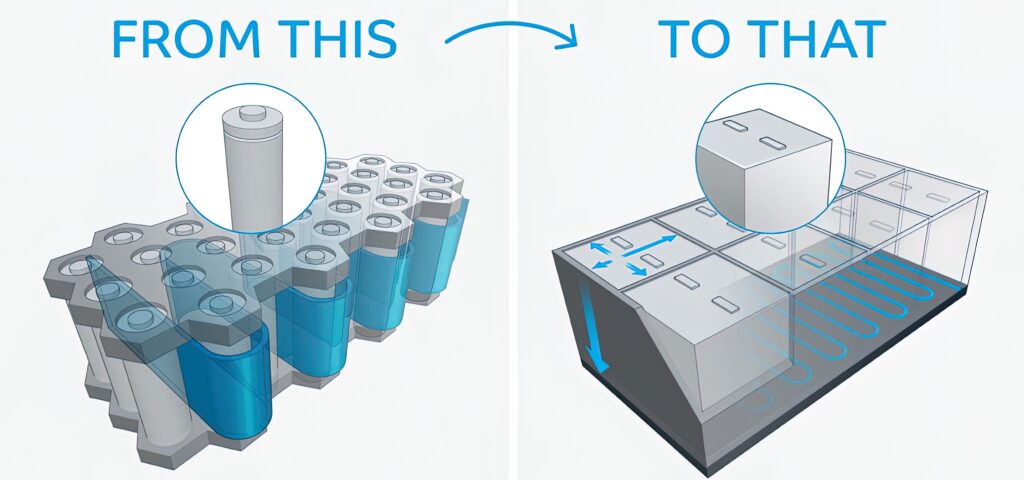

Engineers at materials firm SABIC have patented a design for a battery pack using cuboidal cells (writes Nick Flaherty).

The cells are inserted into a structural backbone made from a thermoplastic, and could increase battery pack energy density by 20% or more, with 10% more cells compared to a pack using cylindrical cells , along with simpler connections and cooling.

There are three patents on the design, covering the casings, the intercell connections and a breakable separator that can enhance the thermal management and safety of the pack.

Additional benefits of the design include low internal cell resistance, a more uniform temperature and voltage distribution, safe discharge as a result of any abuse and built-in crash protection with good thermal dissipation. It also provides an effective barrier against cell-to-cell propagation, along with provides easy disassembly and recycling.

Large pouch cells with many parallel layers have extremely low internal resistance. However, thick cells using stacked layers using current pouch cell manufacturing suffer from very high temperatures in the middle layers of the cell, as the heat removal is very poor.

This design uses uncoated short tabs on either side of the electrodes, with the breakable z-folded separator providing the electrical insulation. These tabs are folded at 90º to create a conductive pathway at the sides of the cell.

On top of the folded tabs, there is an internal thermal busbar made from a copper or aluminium foil that enhances heat and electron conduction. This is done on both the anode and cathode sides. With the z-folded separator, there is no shorting between the positive and negative electrodes.

This provides the shortest path for more uniform distribution of electrons and heat, boosting the thermal management.

The backbone creates a cell-to-pack structure where the heat from the cell surface is removed via the backbone’s highly conductive structure. This heat removal is along the plane parallel to the cell surface to a liquid-cooled plate at the bottom of the battery pack, and makes the overall battery pack very compact. The cells are multi-functional, as they can take significant compressive load, and the structure is effective in distributing any impact loads.

To further improve the safety of the cells in a crash scenario, the z-folded separator’s edges are designed to break under severe impact. This creates gaps across the cell that, in combination with a thermally conductive network, would limit the temperature increase at any single point and effectively prevent thermal runaway that can lead to the pack catching fire.

ONLINE PARTNERS