Resting boosts lithium-metal battery cells

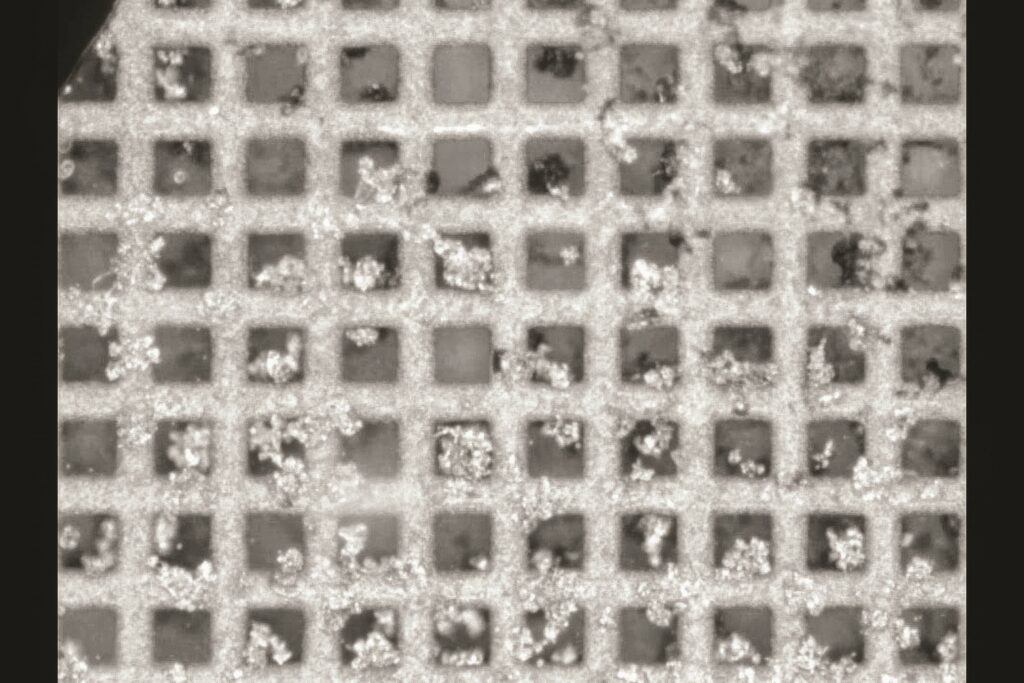

(Image courtesy of Wenbo Zhang/Stanford University)

Researchers have found a key way to extend the life of next-generation lithium-metal batteries, writes Nick Flaherty.

Lithium metal cells can double the range of EVs on a single charge and this is a crucial technology for solid-state cells. The researchers at Stanford University found a low-cost approach, which was to simply drain the battery and let it rest for several hours. This restored battery capacity and boosted overall performance.

This is a different approach to that taken for lithium-ion batteries, where the cells are charged regularly from 20% to 80% capacity, and allowing them to fully discharge can damage the cells.

“An EV with a state-of-the-art lithium-metal battery would lose range at a much faster rate than an EV powered by a lithium-ion battery,” said Prof Yi Cui of the School of Engineering, and professor of energy and engineering at Stanford Doerr School of Sustainability.

“We were looking for the easiest, cheapest and fastest way to improve lithium-metal cycling life,” said Wenbo Zhang, a Stanford PhD student in materials science and engineering who worked on the study. “We discovered that by resting the battery in the discharged state, lost capacity can be recovered and cycle life increased. These improvements can be realised just by reprogramming the battery management software.”

“A car equipped with a lithium metal battery would have twice the range of a lithium-ion vehicle of equal size – 600 miles per charge versus 300 miles,” said researcher Philaphon Sayavong.

Continuous charging and discharging causes lithium-metal batteries to degrade quickly, rendering them useless for routine driving. When the battery is discharged, micron-sized bits of lithium metal become isolated and get trapped in the solid electrolyte interphase (SEI), a spongy matrix that forms where the anode and electrolyte meet.

“The SEI matrix is essentially decomposed electrolyte. It surrounds isolated pieces of lithium metal stripped from the anode and prevents them from participating in any electrochemical reactions. For that reason, we consider isolated lithium dead,” said Zhang.

As the SEI matrix begins to dissolve when the battery is idle, the team looked at what would happen if the battery was allowed to rest while discharged.

“The first step was to completely discharge the battery, so there is zero current running through it,” said Zhang. “Discharging strips all the metallic lithium from the anode, so all you’re left with are inactive pieces of isolated lithium, surrounded by the SEI matrix.”

“We found that if the battery rests in the discharged state for just one hour, some of the SEI matrix surrounding the dead lithium dissolves away,” Sayavong said. “So, when you recharge the battery, the dead lithium will reconnect with the anode, because there is less solid mass getting in the way.”

Cui added: “Previously, we thought this energy loss was irreversible, but our study showed we can recover lost capacity simply by resting the discharged battery.”

Using time-lapse video microscopy, the researchers visually confirmed the disintegration of residual SEI and subsequent recovery of dead lithium during the resting phase.

This has implications for the design of the e-mobility platform. The existing management system can be programmed to discharge an individual module completely, so it has zero capacity left. This does not require expensive, new manufacturing techniques or materials.

“You can implement our protocol as fast as it takes you to write the battery management system code,” said Zhang. “We believe that in certain types of lithium-metal batteries, discharged-state resting alone can increase EV cycle life significantly.”

Click here to read the latest issue of E-Mobility Engineering.

ONLINE PARTNERS