Reliability boost for aluminium cells

Researchers in the US have developed a high-power solid-state battery using aluminium that avoids previous reliability issues (writes Nick Flaherty).

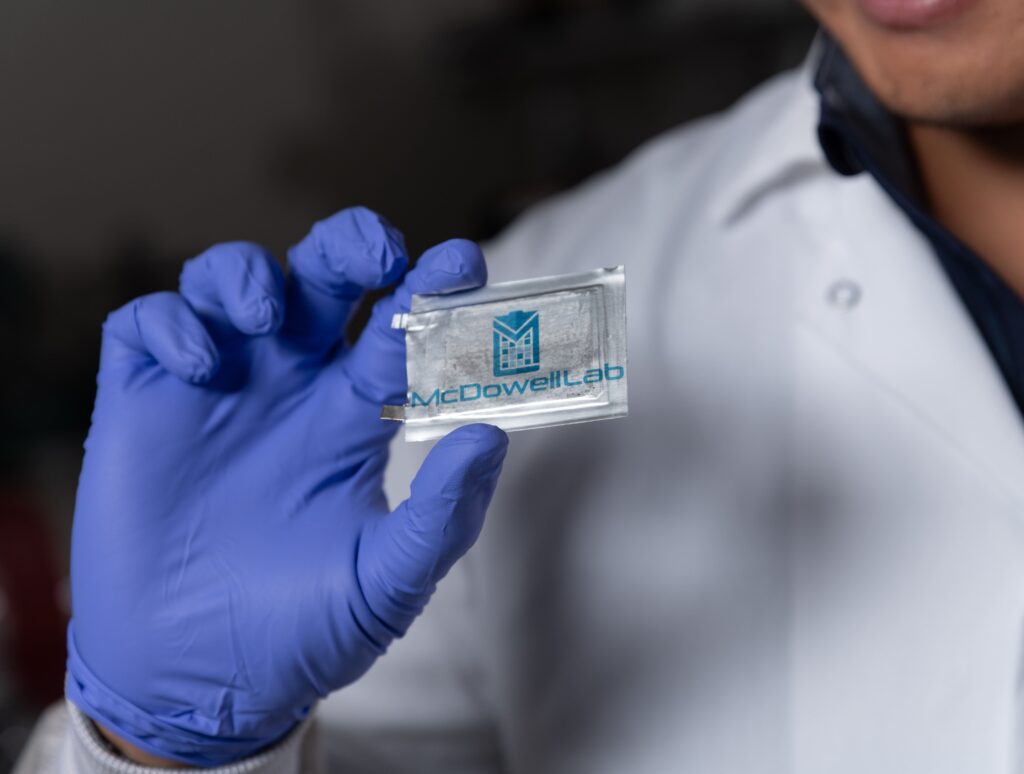

The team, from the Georgia Institute of Technology (GATech), worked with Novelis, which manufactures aluminium and is the world’s largest aluminium recycler, on sheets with different microstructures of other materials.

Despite a high energy capacity of 990 mAh/g without changing its volume, aluminium tends to fracture during charging and discharging and so fails after a few cycles, so the researchers tested more than 100 versions with different materials added to the aluminium foils to understand their behaviour in a solid-state battery.

The project combined non-pre-lithiated aluminium foil negative electrodes with engineered microstructures of indium in an all-solid-state lithium-ion cell. The 30 µm-thick Al94.5In5.5 negative electrodes were combined with a Li6PS5Cl solid-state electrolyte and a LiNi0.6Mn0.2Co0.2O2-based positive electrode in a lab-scale cell that delivered hundreds of stable cycles with high current densities of 6.5 mA/cm2.

The chosen microstructure enables improved charging and discharging within the aluminium matrix, opening up the use of aluminium batteries in EVs and aircraft, according to the team.

“We needed to incorporate a material that would address aluminium’s fundamental issues as a battery anode,” said Yuhgene Liu, a PhD student and researcher on the team. “Our new aluminium foil anode demonstrated markedly improved performance and stability when implemented in solid-state batteries, as opposed to conventional lithium-ion batteries.”

Associate professor Matthew McDowell, in the School of Mechanical Engineering and the School of Materials Science and Engineering at GATech, added, “One benefit of our aluminium anode is that it enables performance improvements, but it can also be very cost-effective. On top of that, when using a foil directly as a battery component, we actually remove a lot of the manufacturing steps that would normally be required to produce a battery material.”

Click here to read the latest issue of E-Mobility Engineering.

ONLINE PARTNERS