Scoping out motors/inverters

(Courtesy of Yokogawa)

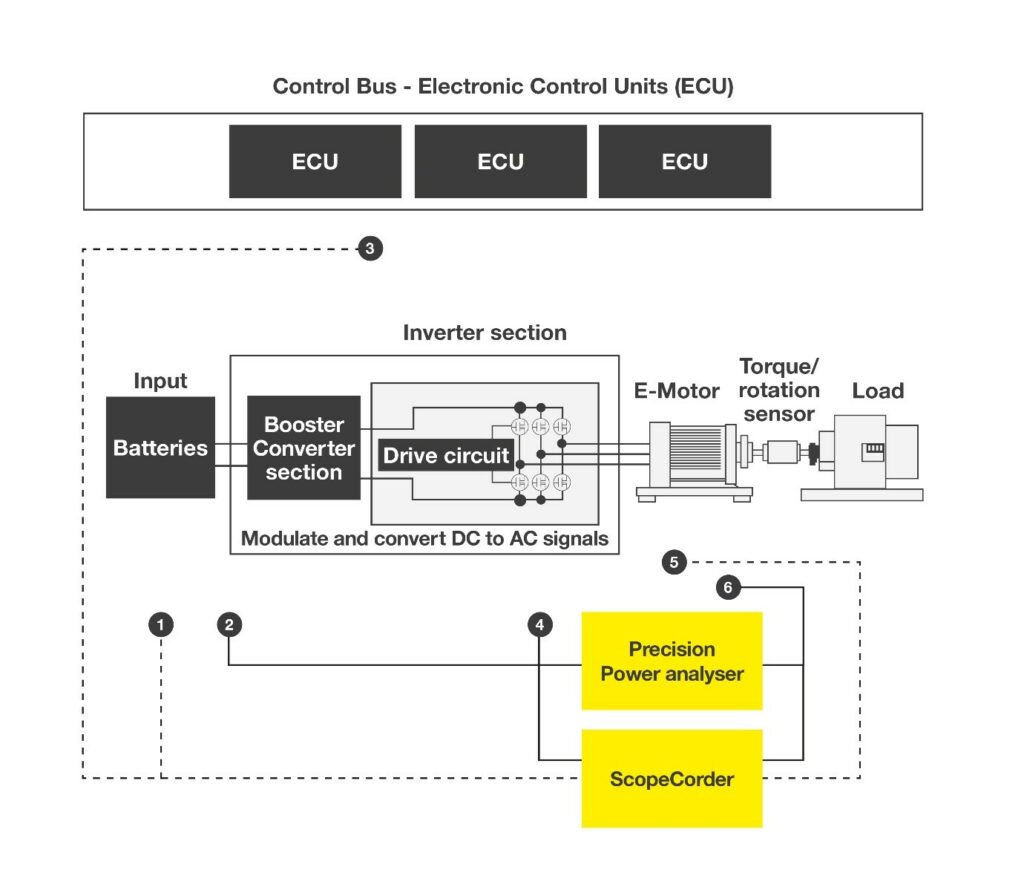

The accurate analysis of inverter waveforms without interference from switching noise is a key part of evaluating the motor drive circuit, driving the need for a class of test equipment called a ScopeCorder (writes Nick Flaherty).

Between 16 and 18% of the total power in an electric car is consumed as losses in the electric drive system. Electric and hybrid car manufacturers therefore need to accurately evaluate motor and inverter control in order to achieve greater efficiency and so provide longer range.

While the debugging and testing of embedded electronics, ECUs and comms bus signals can be performed using mixed-signal oscilloscopes, ScopeCorders are better suited for evaluating electromechanical systems in an electric car over prolonged periods and with a higher amount of electrical and mechanical measurement channels included.

A ScopeCorder can be combined with a calibrated power analyser to provide the data required for compliance and efficiency testing.

Improving the efficiency of a powertrain design is achieved by reliable measurements across every stage of the development cycle. Compliance testing in particular requires adherence to standards such as NEDC and WLTP for efficiency and emissions.

This places greater demands on inverter motor powertrains and drivetrains. Testing them requires greater precision, wideband measurements and a versatile set of voltage and current input ranges often aided by compatible sensors.

Testing the powertrain requires multichannel electromechanical measurements at high accuracy to ensure compliance with standards while extracting efficiency. A single power analyser connected to inputs such as the battery, booster converter and the three-phase motor along with mechanical measurements from torque and speed sensors is a suitable test set-up.

This allows simultaneous measurement of torque, rotation speed and direction, along with electrical parameters such as voltage, current and power to give a holistic evaluation of charging, discharging and powertrain efficiency.

Measurements of conversion efficiency, harmonic content and the battery charge-discharge process in compliance testing should not only be highly accurate but also be repeatable and stable over the specified ranges.

Simultaneous measurement of normal values with harmonics is essential for over-modulation analysis of pulse width modulation waveforms and high-speed measurement of power fluctuations.

Evaluation of inverter signals needs to account for the harmonic superimpositions from the switching circuit. Minimising the interference from this switching noise in the measurement requires isolated inputs and high-speed sample rates in combination with advanced filtering capabilities.

A ScopeCorder can provide analysis of electrical and physical performance parameters together with control bus signals such as CAN or LIN bus data transmitted by the powertrain management system. This also provides waveform trend calculations and analysis of relationships between different system components.

The flexible modular inputs combine electrical and physical (sensor) measurements with input via CAN or LIN serial buses in a single overview. This includes measurement of frequency, temperature, distortion, acceleration and other signals, and allows real-time signal analysis by capturing and analysing transient events and trends for up to 200 days.

ONLINE PARTNERS