Paradigm shift in gear control

Hyundai has developed an Active Shift Control (ASC) transmission technology for hybrid electric vehicles that it says is the world’s first (writes Nick Flaherty).

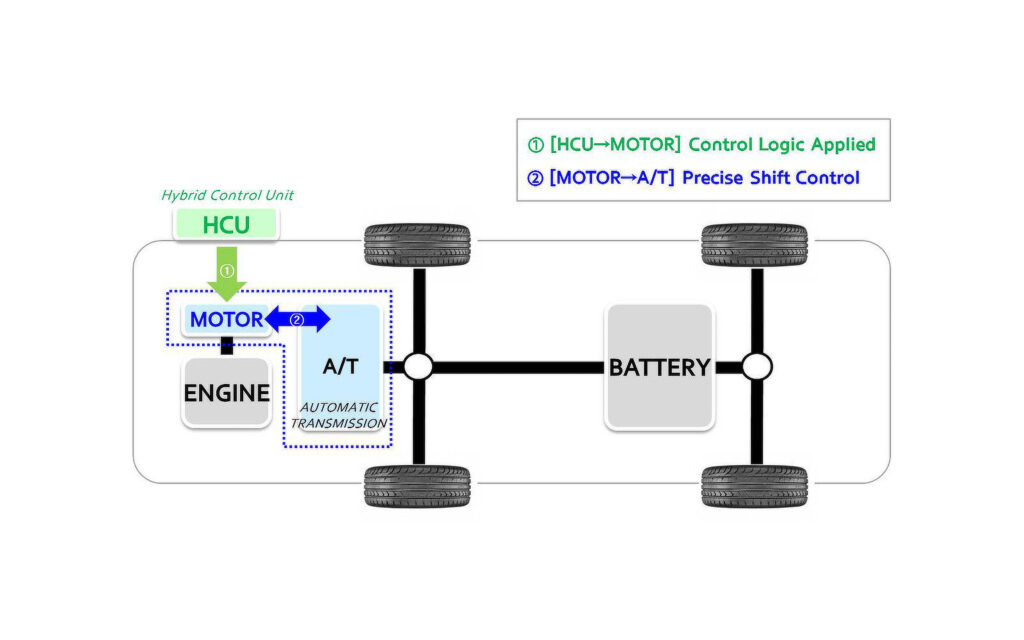

The system uses software in the Hybrid Control Unit (HCU) to monitor gearshifts 500 times per second, adjusting the transmission rotation speed for faster shift times.

New control logic software in the HCU then controls the electric motor to align the rotational speeds of the engine and transmission to reduce gearshift time by 30%. This also provides smoother gear changes despite quicker shift times, saving fuel.

Conventional hybrid vehicles do not have torque converters, as they lose energy during the shift; instead the ASC technology allows the hybrid’s electric motor to take control of the shifts. The monitoring comes from a sensor installed inside the electric motor sampling at 500 Hz to synchronise the rotational speed with that of the engine.

This reduces shift time from 500 to 350 ms, improving the acceleration and fuel economy. The shorter shift time also increases the durability of the transmission by minimising friction during shifts.

The technology will be used in the upcoming Sonata Hybrid and Hyundai and Kia hybrids.

ONLINE PARTNERS