Inverter doubles as a charger

Bel has developed a three-phase wide range bidirectional inverter that can be used as an onboard charger as well as a power source for external equipment (writes Nick Flaherty).

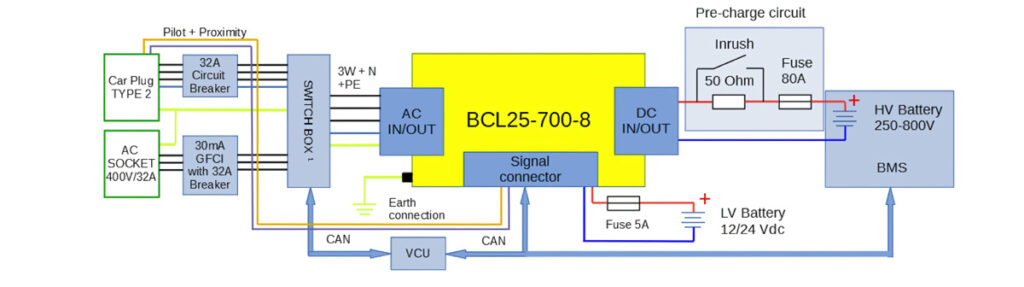

The key innovation for the BCL25-700-8 is a wide DC output range from 250 to 800 V, with a constant current of 60 A across the voltage range and both single and three-phase inputs and outputs.

The multi-phase bidirectional capability comes from the conversion topology, which is a proprietary design. The inverter uses 1200 V silicon carbide (SiC) MOSFET transistors that have a 96% efficiency in three-phase operation at 400 V, and 97% at 480 V. It is the MOSFETs that allow the 250-800 V output range.

The output is 6.6-7 kW in single phase and 22-25 kW in three phase. In DC-AC output mode it allows a vehicle to create its own local grid for powering motors, air conditioning or power tools.

The inverter would typically be charged from a single- or three-phase AC source with Mode 1, 2 or 3 charging. However, it has been tested with the vehicle control units from Vector and would support DC Mode 4 charging. Future versions will include DC charging.

Supporting the different phases requires different pin configurations in the connector. The single-phase connection pins used in the EU are different from those in the US, which use a split phase. The 240 V (not 120 V) US variant input uses pins 2 and 4.

The inverter can also support a softstart function for induction motors that have a high inrush current. The function needs a slow ramp-up of the voltage to full power, and there are specific pins on the connector (pins 7 to 10) to carry the signal from the CAN bus to activate it.

The liquid-cooled inverter also includes the EMC filter inside it. That makes the inverter larger than one with an external filter but allows it to be qualified to IEC 61851 for electrical safety.

The unit can also be installed upright or horizontally in a vehicle; a U-shaped cooling system covers the SiC transistors on the input, which are the main source of heat regardless of the orientation. The U-shape ensures that bubbles of coolant rise to remove the heat from the system, and the system requires a relatively low flow rate, of 10 litres/minute.

The inverter also has active HV DC interlock monitoring, which is part of the functional safety requirement. When the interlock is activated it switches off the current immediately. This interlock is triggered by a switch in the HV connector. Four of the inverters can be used in parallel, for an output of 100 kW in a truck or bus, but it can also be used in light commercial vehicles, delivery vehicles, construction and mining equipment, tow tractors and marine applications.

ONLINE PARTNERS