Bus is on route to the future

Daimler has developed an electric bus platform that will accommodate the next generation of batteries and fuel cells (writes Nick Flaherty).

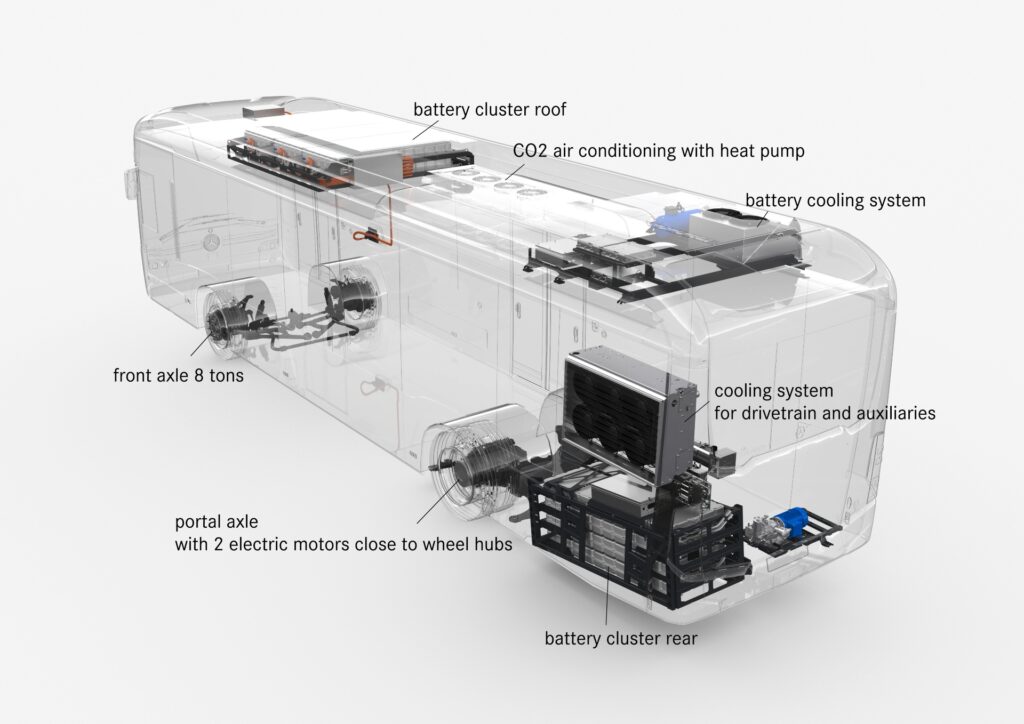

The powertrain of the eCitaro bus is based on the proven ZF AVE 130 electric axle, with 125 kW electric motors at the wheel hubs providing 485 Nm (358 lb-ft) of torque. They also act as alternators during braking, transforming the kinetic energy of the vehicle into electricity.

The bus can house up to 243 kWh of nickel manganese cobalt oxide (NMC) lithium-ion batteries, split across up to 10 modules, each supplying around 25 kWh. Two modules are on the vehicle roof while four in the rear take the place of the IC engine and transmission. Another two or four modules can be mounted on the roof to provide as much space as possible for passengers inside.

Each battery consists of 15 modules as well as a control unit for monitoring and balancing the charge in the 12, 37 Ah cells in each module.

The system is designed to use the next generation of NMC cells that will be available in two years’ time. These cells will provide 33 kWh per battery module with a total capacity of up to 330 kWh, to be introduced on an eCitaro G articulated bus.

Operators can trade off the range and weight of the bus using between six and 10 of the modules. Using 10 maximises the bus’ range for a weight of 13.44 tonnes, while six reduces the weight as well as the cost of purchase but means the bus may have to be charged during operation.

The current version of the eCitaro uses a Combo-2 charging plug above the front wheel arch on the right-hand side of the vehicle in the direction of travel, to meet the requirements of the German Association of Public Transport Operators (VDV).

There will also be an option to charge the eCitaro via a pantograph from the top of the bus. This will use either an integral pantograph on the roof for charging while in use or charging via a stationary pantograph at a charging station.

Thermal management has been a key part of the design. At an outside temperature of -10 C, the energy consumption of a city bus doubles compared to daytime temperatures, cutting the range by half as energy is needed for heating the passenger area.

The designers have reduced the energy requirement for heating, ventilation and climate control by about 40% to compensate for that.

The batteries also need to be cooled, however, especially during charging. So a separate battery cooler mounted on the roof keeps the battery packs at the correct temperature, although at high outside temperatures, the passenger climate control system is used to boost the cooling.

In the driver compartment, a power meter replaces the rev counter, displaying the state of power demand and/or energy recovery rate. The driver also receives information about the state of charge of the batteries and can access the range, available power and a charging indicator on a central display.

The design of the roof, with integrated heavy-duty rails for the batteries, is derived from the system used for the tanks in the Citaro NGT gas-powered bus and is segmented so that individual sections can be removed for servicing.

Alongside the NMC cells, Daimler is also planning to use solid-state batteries. These will provide a total capacity of about 400 kWh in the eCitaro and even more in a larger, articulated bus.

They have a different-shaped cell from the NMC version, so the two are not interchangeable and they are not suitable for fast charging. As a result, city buses equipped with them will cover different types of routes.

To provide a longer range than either NMC or solid-state battery packs, Daimler also plans to use a hydrogen fuel cell to generate electricity to drive the motors, but the company has not specified whether it will use a solid oxide source or biogas.

ONLINE PARTNERS