‘Hairpin’ ambition for motors

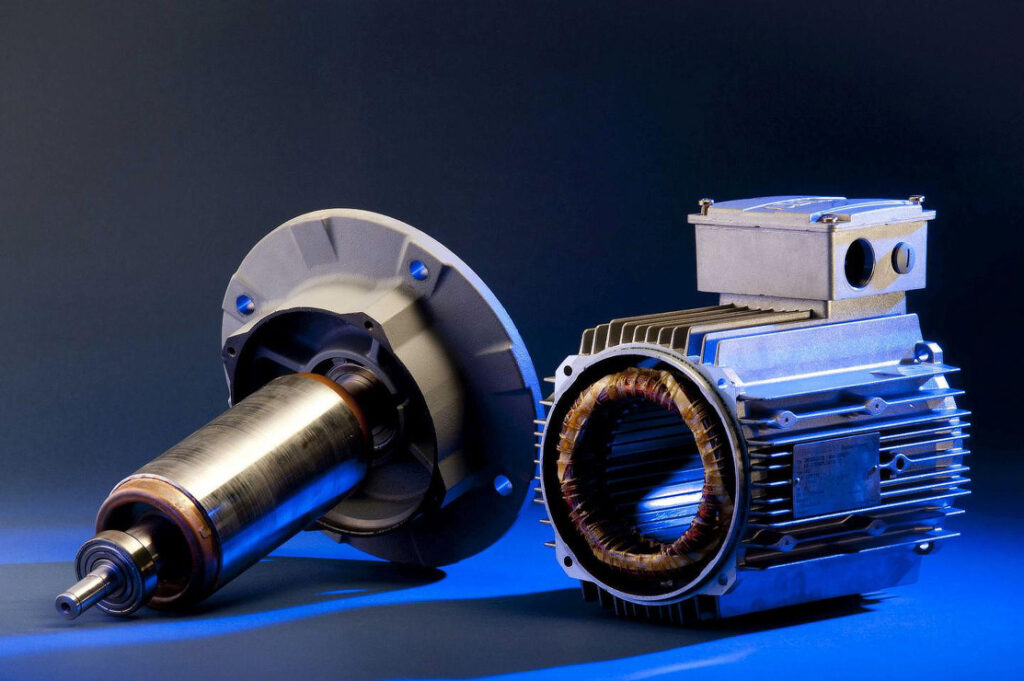

(Courtesy of Martin Lober/KIT)

Researchers in Germany are developing new automated production techniques for electric motors for cars, whether they are powered by batteries or fuel cells (writes Nick Flaherty).

The €1.2 million Plant Engineering for the Production of Stators by Hairpin Technology project brings together teams from the Karlsruhe Institute of Technology (KIT) and the Fraunhofer Project Group for New Drive Systems in Karlsruhe.

The stationary element that acts as the field magnet – the stator – is manufactured from a coil, which can require complex manufacturing techniques. The team is looking at using a technique called ‘hairpin’ technology, where the individual segments of the stator coil are formed like hairpins, for high-volume production of motors.

The project aims to develop detailed process knowledge around the technology with production systems for medium-sized companies supplying components into EV producers.

ONLINE PARTNERS