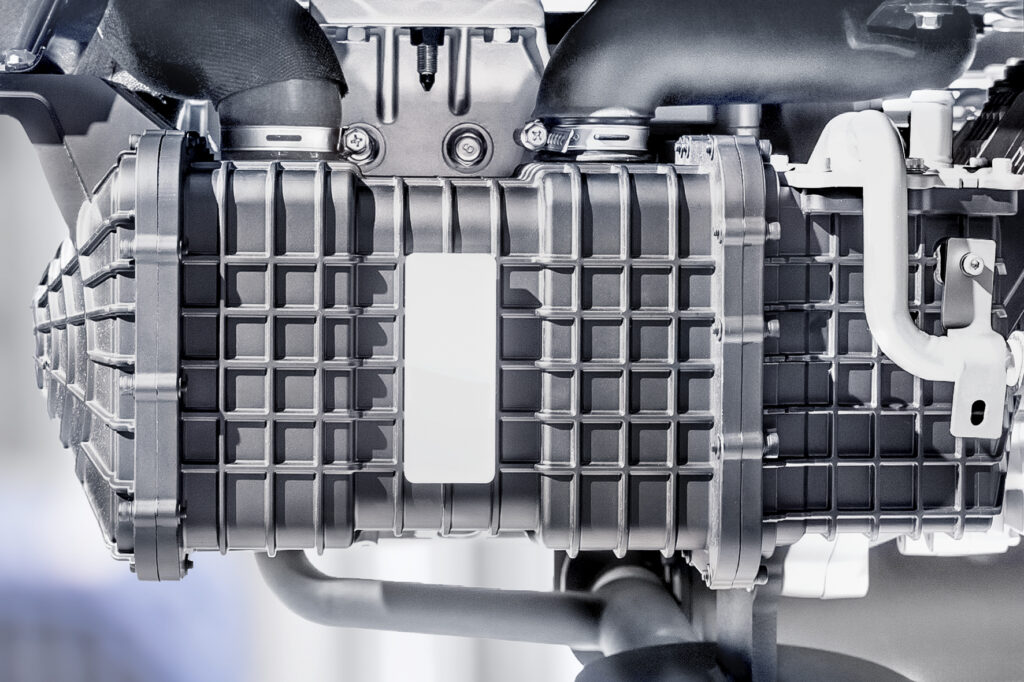

Hydrophobic adhesives advance PEM fuel cell humidifier durability and production

(Image courtesy of Wevo-Chemie)

Maintaining optimal humidity levels in PEM fuel cells has become a critical engineering challenge as the technology scales toward mass production. The membrane depends on precisely controlled moisture to maintain ionic conductivity. Small deviations compromise performance or durability. Humidifiers rank among the most demanding subsystems, facing high humidity, elevated temperatures and chemical exposure. The materials holding these components together must stay stable, flexible and impermeable over thousands of operating hours.

Wevo-Chemie has developed adhesives, sealants and potting compounds tailored for this application. Built on polyurethane, epoxy and silicone chemistries, these formulations meet demands in both flat-sheet and hollow fibre humidifiers. They deliver gas-tightness and hydrolysis resistance with low ion content and minimal VOC emissions. These traits preserve membrane integrity and avoid electrochemical degradation.

Flat-sheet membrane humidifiers stack several hundred alternating layers of membrane and spacer materials into a single module, then seal into a housing to prevent gas leakage. Wevo’s hydrophobic polymer systems repel water at the molecular level to enhance hydrolysis and temperature resistance. Their low glass transition temperature keeps them elastic rather than brittle. This proves critical during cold starts with severe temperature differentials.

These systems also bond effectively to challenging substrates like polyolefins, polyphenylene sulphide and fluorinated membranes. This compatibility opens design possibilities and supports automated assembly, where consistent adhesion across diverse materials drives high-volume manufacturing.

Hollow fibre membrane humidifiers pot bundles of fine tubular membranes into support structures at both ends, similar to water filtration cartridges. The resin must penetrate narrow spaces between fibres, wetting the bundle without clogging tubes or excess heat that damages membranes. Wevo’s potting compounds control the exothermic reaction during curing, preventing oxidative degradation while ensuring complete penetration. Their hydrophobic polyurethane chemistry blocks reactions with residual moisture, eliminating bubbles that weaken joints or reduce efficiency.

These materials integrate with standard mixing and dosing equipment for semi- or fully automated lines. Viscosity and pot life adjust to specific workflows, with room-temperature curing or thermal acceleration via ovens or infrared for faster cycles. They also seal housings, water inlets, bypass valves and internal zones, reducing qualified materials in the supply chain for easier validation.

Wevo works closely with fuel cell and electrolyser manufacturers to refine formulations. Tuning gas permeability, hydrogen resistance and substrate adhesion at the molecular level supports higher power density, durability and cost targets. As hydrogen systems scale from demonstration to deployment, these materials deliver real-world reliability alongside electrochemical advances.

Click here to read the latest issue of E-Mobility Engineering.

ONLINE PARTNERS