Parker Chomerics launches high-performance THERM-A-GAP GEL 120 for advanced thermal management in electric vehicles

Parker Chomerics has launched THERM-A-GAP GEL 120, a thermal interface material designed to meet the rising thermal management demands in e-mobility systems. Its thermal conductivity of 12.0 W/m-K sets it apart from typical interface materials, enabling more efficient heat transfer in critical applications like EV battery thermal management, power electronics cooling, and automotive control units where maintaining low junction temperatures is vital.

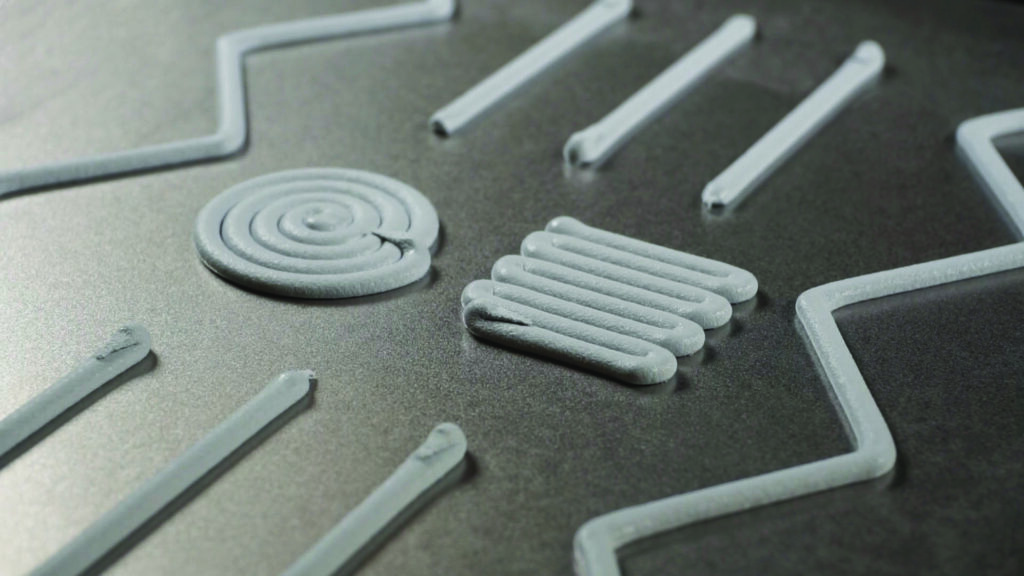

This gel fills air gaps from 0.5 mm to 4 mm, accommodating common assembly tolerances and surface irregularities between components, PCBs, heat sinks, and enclosures. Being a one-component, fully cured gel, it requires no secondary curing and conforms with very low compressive force, which reduces stress on sensitive electronics and solder joints during assembly.

It operates reliably across temperatures from -50°C to +200°C, suitable for the thermal cycling in automotive and energy storage environments. Electrical insulation is assured with a dielectric strength of 5 kVac/mm and volume resistivity of 10¹³ Ωcm, essential for high-voltage EV systems. The gel supports high-volume manufacturing with precise robotic dispensing at 25 g/min flow rate and is available in various container sizes from 10 cc to 2500 cc.

As power density in e-mobility platforms increases, materials like THERM-A-GAP GEL 120 that combine high thermal conductivity with easy application are crucial to maintaining performance and reliability of electronic components.

Click here to read the latest issue of E-Mobility Engineering.

ONLINE PARTNERS