Wax works well for conducting heat

Researchers in the US and China have developed an economic but efficient battery thermal management strategy using paraffin wax (writes Nick Flaherty).

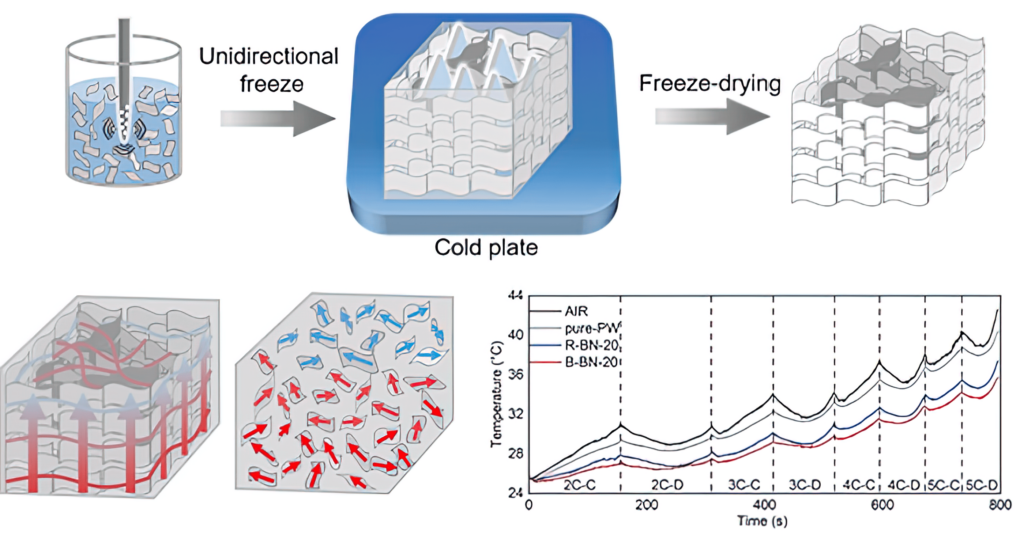

The 3D, interconnected, thermally conductive boron nitride network greatly improves thermal conductivity compared to random distribution.

“We designed a 3D network of boron nitride, and systematically studied its effect on the thermal management performance of power cells,” said Professor Bing Zhang of Zhejiang University in China.

The sheets of hexagonal boron nitride (h-BN) were homogeneously dispersed in an aqueous solution of polyvinyl alcohol to form a suspension. The suspension was then poured into a square mould with a copper bottom surrounded by polymethyl methacrylate to achieve unidirectional growth by freezing the mixture using liquid nitrogen.

The h-BN sheets were then squeezed by the growing ice crystals to form an ordered and interconnected network. After further freeze-drying to sublimate the ice, an h-BN aerogel with rich pores and a highly ordered structure was obtained where the connected h-BN sheets form a continuous heat transfer path.

This ice-template method is simple, environmentally friendly and cost-effective for large-scale production.

The structure of the h-BN aerogel varied a lot according to the amount of h-BN, with a 20 wt% loading leading to a condensed layered structure with shorter distances between layers compared to a 10 wt% h-BN loading. At a loading of 30%, the parallel layer structure changes to a honeycomb structure that is less effective at thermal management.

“We found that the h-BN constructed by the ice-template method with varying temperature gradients showed structural differences in different directions,” said Prof Zhang. “Generally, structure determines performance, and different structures in different directions mean a greater spread of performance. By creating a composite with paraffin wax [h-BN/PW], we could achieve excellent anti-leakage performance and ultra-fast heat dissipation performance in lithium-ion batteries.”

The composite with a 20 wt% loading of h-BN can guarantee a highly ordered network, and exhibited high thermal conductivity of 1.86 W/m/K – four times greater than that of random dispersed h-BN involved PW and nearly eight times greater than that of bare PW.

The optimal thermal conductive composites demonstrated ultra-fast heat dissipation as well as leakage resistance for lithium-ion batteries. The heat generated by the batteries can be effectively transferred under the working state and the surface temperature kept 6.9 C lower with a continuous charge-discharge rate of 2 to 5 C compared with that of bare one which illustrated great potential for industrial thermal management.

ONLINE PARTNERS