Third-generation e-power powertrain boosts efficiency

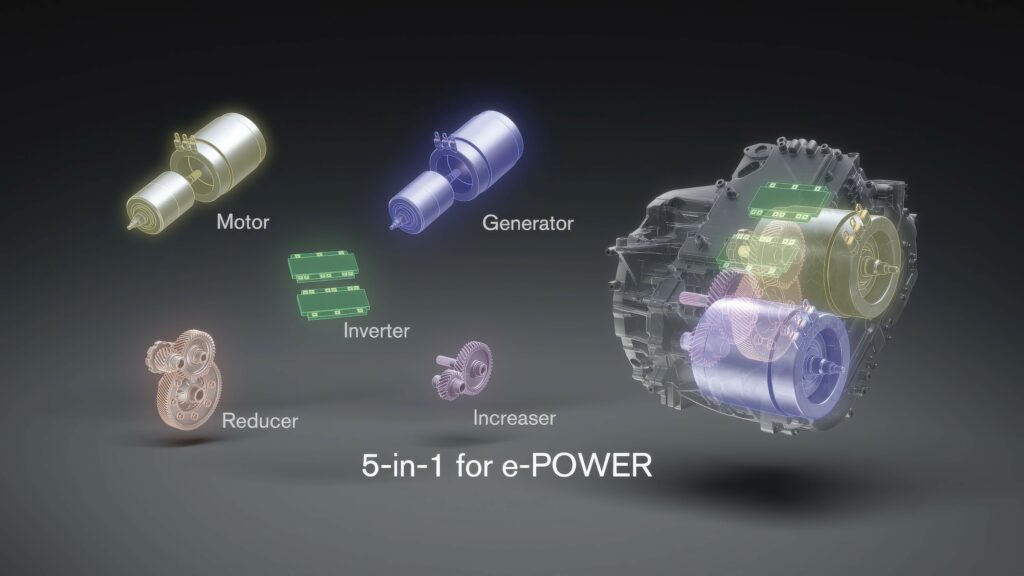

Nissan has launched its third-generation hybrid electric powertrain, combining five functions in one unit, writes Nick Flaherty.

The e-power platform uses a petrol engine as a generator for the electric motors with a 2.1 kWh battery. The third-generation design optimises the packaging of the motor, inverter, electric generator and reducer and increaser gear systems.

Nissan has also redesigned the combustion engine to increase the fuel efficiency because it can run at a constant frequency.

The 5-in-1 powertrain has been designed for more rigidity at the fixed frequency, minimising vibrations at the key resonance points. This reduces cabin noise and boosts the efficiency of the engine, particularly at higher speeds.

Combined with improvements to engine calibration and sound insulation, vibration is reduced under load. Overall, power is up by 11 kW, at a maximum of 151 kW. The battery capacity is unchanged at 2.1 kWh.

The three-cylinder 1.5 litre turbo engine has also been redesigned using a principle Nissan called Strong Tumble & Appropriately stretched Robust ignition Channel (STARC). The ‘tumble’ refers to the in-cylinder gas flow – the way the air–fuel mixture swirls inside the cylinder. By making this flow ‘strong’, Nissan can more effectively mix the fuel and air using the fixed rpm rate. The ‘appropriately stretched robust ignition channel’ is an improved ignition process that reliably burns a more diluted air–fuel mixture at a high compression ratio, improving combustion efficiency that raises thermal efficiency by 42%.

A larger turbo brings efficiency gains and allows a 200 rpm reduction in engine speeds during highway driving, contributing to the lower overall noise level. It also means that the variable compression ratio technology used on the previous version has been rendered redundant, helping to reduce size and weight.

Click here to read the latest issue of E-Mobility Engineering.

ONLINE PARTNERS