Munro Series-M 4×4

(All images courtesy of Munro Vehicles)

It’s a kind of magic

Peter Donaldson reveals the wizardry behind a tough 4×4 utility EV platform that promises unlimited variation

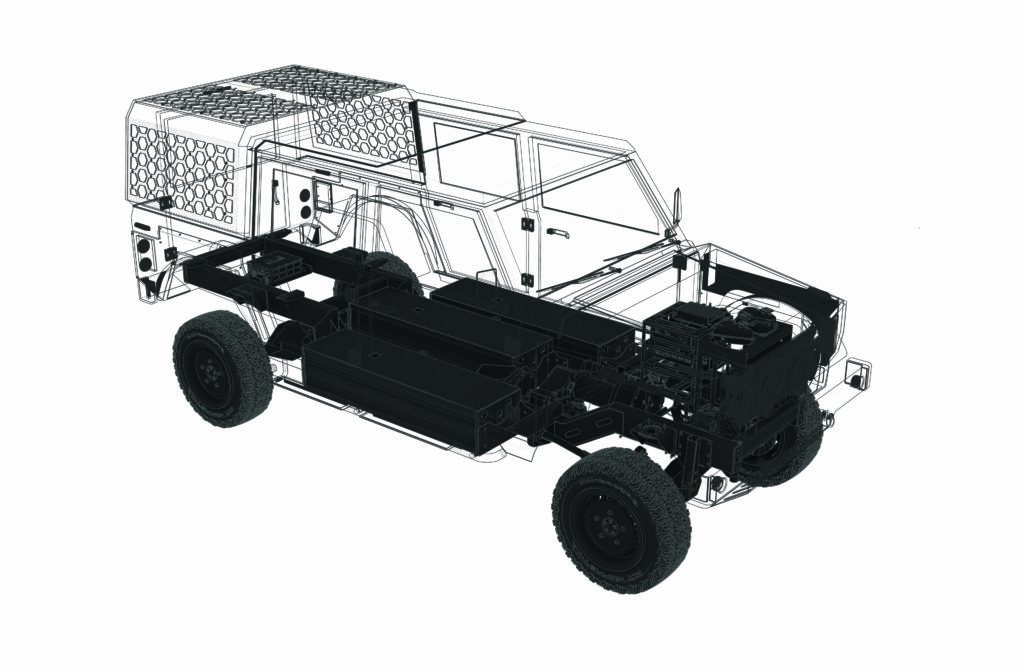

Munro Vehicles’ Series-M is a family of rugged 4×4 EVs emphasising high off-road performance with on-road manners good enough to be accepted in polite company. However, the use of 24 V bus and truck ancillary components reveals that it is intended to be more industrial equipment than status symbol by nature. This impression is reinforced by a design service life measured in decades along with the characteristics of ease of maintenance, upgrade, customisation and refurbishment. These attributes are instilled through battery chemistry, modularity, component selection and positioning, all underpinned by heavy-duty construction using extremely durable materials.

Russell ‘Russ’ Peterson, who co-founded the company with Ross Anderson, takes us through the key engineering choices that shaped the Series-M vehicles, which are available in utility, truck and custom-body-ready chassis cab styles. They also offer a choice of either 170 or 280 kW e-motors, which define the M170 and M280 models respectively, both with a maximum payload of 1050 kg, 1600 L of cargo capacity, and towing capacity of 3500 kg.

Body-on-chassis reasoning

Regardless of body style and motor output, all Series-M vehicles are based on a ladder frame chassis made of 5 mm thick steel, to which all the driveline and body components are bolted.

“Originally we were going to go down the monocoque route, but the biggest driver behind going for a body-on-frame design was serviceability,” Peterson says. “We took the approach that everything on the vehicle should be serviceable, it should be field repairable, it should be modular and it shouldn’t be beholden to any particular component.”

Even with a truck that has taken six or seven years of beating in a mine or a quarry – probably the toughest of all industrial environments on vehicles – it should be worthwhile refurbishing it simply by dropping a new body onto the original frame, he emphasises.

Another key issue that favoured a body-on-chassis architecture, he says, was mitigation of noise, vibration and harshness (NVH). The Series-M vehicles have live axles front and rear, and the body mounts provide an extra opportunity to isolate the cabin from the drivetrain. “This, surprisingly, has been a big focus in our target market because there’s an expectation now that these vehicles should have Range Rover levels of NVH isolation – so that was also a driver for us.”

The main design goal for the chassis frame itself was torsional rigidity, hence the thickness of the steel. Such rigidity is critical for off-road performance, preventing the frame from acting as an unwanted spring, while also contributing to its longevity over years of demanding use.

“We could have gone for a slightly less rigid frame and relied on the body to provide extra stiffness, but we decided not to do that, just for basic flexibility with the design in the future,” Peterson adds. “If we want to go to a single cab layout or a cab-forward layout, we’re not then sacrificing torsional rigidity; we made sure that the frame could stand on its own.”

The chassis also has to contribute to the vehicle’s crashworthiness, enabled by impact-absorbing crushable modules that can be removed and replaced. These elements can also be left off vehicles built purely for off-road use, making way for solid elements that allow the truck to push heavy, hard objects out of the way, which might be vital in an emergency down a mine or to escape from an ambush in military use, for example.

Modular focus

Modularity is a central aspect of the design, and Peterson emphasises that the Munro team took “a very conscious approach” in the Series-M development to make it as modular as possible for ease of maintenance, among other goals. He says that a power unit can be removed from below in about 45 minutes, or the body can be taken off so that the power unit and other components can be taken out from the top, while a battery pack takes about 30 minutes to remove. There are three packs on the vehicle: one on each side and one in the middle of the frame, he explains, and they can be disconnected, unbolted and dropped down with a forklift.

“That hot swap capability in the field is pretty unusual. Most cars have to have a significant tear-down to be able to do that, whereas with a forklift, a flat area and a couple of field techs, it would take an hour or an hour and a half to replace a pack,” he says.

“The whole architecture is modular. There’s very little amalgamation of components, and for repairability we can break down every system,” he notes. With the batteries, for example, the pack lids can be removed to give access to the modules, the modules can be opened to reach the cells and the other components can be unbolted. They also decided not to use potting compound because it would make removing cells more difficult. Everything can be broken right down to its lowest level and repaired, he emphasises.

“This is all driven by the commercial focus on total cost of ownership (TCO). If you have a battery failure and you need a new pack, that blows the TCO out of the water, whereas if you’ve got this repairable architecture, then you start to see the benefits of that in a commercial environment.”

Design for repairability

Repairability was also the driver behind the Series-M vehicles’ removable body panels. “The first question insurance companies ask is how much it costs to repair a corner and how much it costs to repair a side impact. So, the cheaper you can make that, the more attractive it is, the easier it is to insure and the better it is in terms of TCO.”

Ease of refurbishment is also a key consideration here, with vehicles for use by utility companies particularly held in mind. After several years of service, these vehicles are often mechanically sound but let down by their aesthetics, with not a straight panel left on them and ruined interiors, he notes. Making them easy to refurbish at relatively low cost to lengthen their service lives and improve their resale value was an early design goal.

Removable body panels also ease maintenance, as does the positioning (‘stacking’) of components that may have to be removed and replaced. “We have been very careful about choosing the order we stack things in. So, the components that we know have a really high mean time between failures go at the bottom of the stack, and then likely service items go further up,” he explains. “For example, the inverter for the motor is right at the bottom of the stack because there is a very slim chance that it will ever need to be replaced, while water valves with moving parts are put towards the top of the stack.”

Munro’s decision to use batteries based on lithium iron phosphate (LFP) was driven by safety, particularly in harsh operating environments in which the pack could be damaged. “Even with as much protection as we can put around the battery pack, there are still potential scenarios that present risks of catastrophic failure through the environment alone or a mishap and we wanted to make that risk as low as possible,” he says.

While underground work is far from Munro’s only focus for the Series-M vehicles, it feeds into the high levels of ruggedness they want, and they are not facing tight limits on weight and volume. “For us, the energy density doesn’t matter as much as safety or longevity. An LFP battery pack, when managed correctly, will outlive an NMC [nickel manganese cobalt] pack; it’s a much more stable chemistry.”

Munro builds its own packs based on prismatic cells; a form factor chosen because it eases repair of the pack. The cells come from China’s Envision AESC, which also supplies Nissan. Using a standard size and shape also improves security of supply because alternative manufacturers can be found more easily, Peterson points out. “We wanted prismatics of a standard size and shape from manufacturers whose cells are used in EVs all over the world and are well regarded for their high standards.”

Voltage choices and thermal management

Both the M170 and the M280 have the same 85 kWh battery pack and, for the moment, a 400 V architecture. The latter is a conservative choice that could change eventually. “The whole industry is going to 800 V, and when we talk about energy density, charge speed, discharge power and cable weights, and the rest, it’s inevitable,” he says. “We picked 400 V for two reasons: one is compatibility with legacy charging infrastructure and the other is the supply chain. We were first designing the vehicle three and a half years ago, and the supply chain wasn’t quite there yet for 800 V. It was cutting edge then, whereas now it is becoming the norm and supply is getting easier.”

Future iterations of the Series-M could be 800 V machines, and the company may even support upgrades to the higher-voltage architecture down the road. “If there is a pathway to do that, then we will do it, but it will come down to cost as to whether customers will go for it, and that depends on how many components will have to be changed, but it’s definitely a consideration.”

Any battery pack intended to operate in extremely hot (or cold) environments needs a powerful and robust thermal management system. As Peterson describes, each of the three packs of the system has a contact heat exchanger in the bottom though which a water-ethylene glycol (WEG) mix flows, which is heated/cooled using a bidirectional heat pump supplemented by an auxiliary high-voltage resistance heater for use in extremely cold climates. Both the heat pump and the auxiliary heater are in the front of the vehicle.

In developing the thermal management system, Munro also wrote its software, which includes a state machine with 12 modes that can heat and cool the cabin, battery, power electronics and drivetrain, for example. “We can harvest drivetrain heat and pump it into the battery pack, for example, for efficiency, and that system is designed to operate in a full range of ambient temperatures.”

Not only is the air conditioning system very small, with only 450 g of refrigerant circulating, but also the refrigerant loop is not used to manage the temperature of either the cabin or the battery packs directly. Instead, it simply moves heat in and out of the WEG loop that cools/heats all the other components.

Almost all the thermal management components are supplied by Webasto, with only the cooling fans supplied by another big-name company, SPAL. All these parts are designed for trucks and buses, chosen for their very high mean times between failures.

The BMS itself is an automotive-grade system from an external supplier, which consists of a main controller within the vehicle’s power distribution unit and subsidiary boards in each pack that monitor key parameters such as voltage, resistance and temperature of the cells to calculate state of charge (SoC) and state of health (SoH) using Munro’s own algorithm.

“We feed our data about the battery pack in, it calculates the values and then SoC is transmitted to the driver with a little bit of manipulation just to create a buffer,” Peterson notes. He explains that the system has a top buffer and a bottom buffer, making its full capacity slightly greater than its 85 kWh usable capacity at about 87 kWh.

At the time of writing, SoH isn’t communicated to the driver because the company’s diagnostics are currently based on bespoke software that runs on laptops that plug into the vehicle, but they are working on an app that will allow customers to see basic diagnostic information, including SoH,

Central motor drivetrain

Converting the electric current to mechanical power is performed using a single, large permanent magnet alternating current motor. This drives a conventional mechanical off-road 4×4 powertrain with a transfer box, centre differential and differentials on the front and rear live axles.

“We do the hardware and software integration of that motor into the drivetrain, and we have done it in a modular way so that if motor technology progresses and we get more cost-effective motors or motors without rare-earth magnets at the right price point and maturity level, then we can swap to a new motor easily.”

Munro’s priorities that led to the selection of this motor were high torque at low speed combined with compactness and low weight. The motor lives in the transmission tunnel where a conventional clutch or torque converter and gearbox would be in an ICE vehicle. “There is a widespread assumption that you don’t need gears if you’ve got an electric motor, but the industry is starting to realise that gearing is critical for efficiency and for getting the most out of a small motor, and multi-speed EV gearboxes have come on a long way.”

The Series-M vehicles feature a two-speed transfer box. “It’s basically a dog clutch, so you have to stop or drive very slowly to change between high and low range – just like an old Land Rover – and it has an electronically controlled locking centre differential, so you can split the drive between the front and the rear,” he explains. “The front and rear differentials are optionally lockable as well, so you can get equal torque and speed at all four wheels.”

Munro made this choice after examining ostensibly higher-tech alternatives, particularly individual in-wheel and hub motors. “The biggest challenge for us with them was the maturity of the technology and limited supply chain options,” Peterson says. However, traction was also an important consideration, he adds. “Say you’ve got hub motors with 100 kW at each corner, so 400 kW total. Once you lose traction on three wheels, you’ve only got a quarter of your torque and power available,” he explains. “You need to be able to deliver all the torque to whichever wheels have the traction.”

The Series-M’ regenerative braking system can use the motor’s full torque to slow the vehicle, blended in by a dynamic torque controller that takes into account the battery’s SoC, how far the brake pedal is pressed and other parameters, making it very flexible and dynamic, he emphasises. The vehicle also has multiple drive maps that enable it to adapt to the terrain and the driver’s demands. “When you select low-range, you get a torque conditioner that is more focused on controlling the speed, controlling the grip, so we blend the regen in and out based on what the driver is trying to do. On the road, people are more accustomed to lighter ‘engine braking’ off the throttle and they want a sharp brake pedal, whereas off the road you want hill descent control all the time.”

Conservative suspension

The suspension system is based on coil-sprung live axles front and rear. Peterson notes that Munro experimented with many different types of suspension before settling on this familiar and well-proven concept, eschewing the more radical layouts used in off-road and desert racing machines built for series such as the King of Hammers. “It really boiled down to specifying off-road-ready suspension and an axle layout that has a solid supply chain,” he says.

“We’ve got progressive coil springs all round, so we can tailor it for different load cases and tune it to be flexible. It’s a fine balance, and it’s also again something we’re not going to live or die by – we’re constantly evaluating what the right solution is off-road, but this is what we think is achievable now.”

Munro uses a blend of in-house and bought-in suspension components, for example sourcing trailing arms and radius arms from Adrenaline 4×4, a small company from the English Midlands that has built a solid reputation among serious off-roaders.

One major challenge in engineering the suspension of an off-road capable EV is weight, which makes striking the balance between axle articulation and roll control difficult. Munro is exploring a mixture of conventional and innovative solutions here. “We are able to control a lot of the roll just with the suspension geometry and the spring and damper rates, but we’re looking into extra control using what is basically a variable torsion anti-roll bar,” he says. “We are looking at some unique ways to have the best of both worlds on and off road, or to make it adjustable from inside the car.”

Munro also has an air suspension system currently under development and testing to ensure its reliability, particularly as far as the airbags and the compressor are concerned. The biggest consideration here is finding a compressor that is both quiet and robust enough. “With a combustion engine you can get away with a loud compressor because you probably won’t hear it, whereas in an EV, a loud compressor is pretty annoying. So, we want a compressor that is nice and quiet, that we know is not going to take in dust and water and will last a long time with very little maintenance.”

Customisation and production scaling

Munro is prioritising customers that really need the Series-M’ off-road capabilities and have demanding, public environmental, social and governance targets. This includes utilities, mining, infrastructure projects, defence, fire, and search and rescue that all present problems for which specialised and customised vehicles built with partners can provide solutions.

Fire and rescue services, for example, increasingly have to deal with wildfires, making the robustness and reliability of vehicles critical features. That means any software mode that could stop the vehicle from driving out of a fire if the battery gets too hot is unacceptable. “We are looking into a keyed switch that overrides such modes in a life-and-death scenario to get the vehicle moving. We’re not quite there yet, but that’s the kind of thing those industries are asking for.”

On the customisation front, the company has already partnered with a specialist company, which takes the base vehicle and puts a fire truck body and firefighting systems on it; a task made much easier by Munro’s pre-installation of the correct wiring loom.

Peterson notes that Munro also has a mature scaling plan that will progressively take them from hand-building one or two prototypes per month in their workshops to a factory set up around bays that will allow them to turn out 15 to 20 vehicles per month. Beyond that, their ‘stretch’ goal is to get to 2000 or 3000 per year. “That plan is less mature, but we have the concepts around what is required to go to that volume.”

Click here to read the latest issue of E-Mobility Engineering.

ONLINE PARTNERS