Multi-kilowatt superconductors

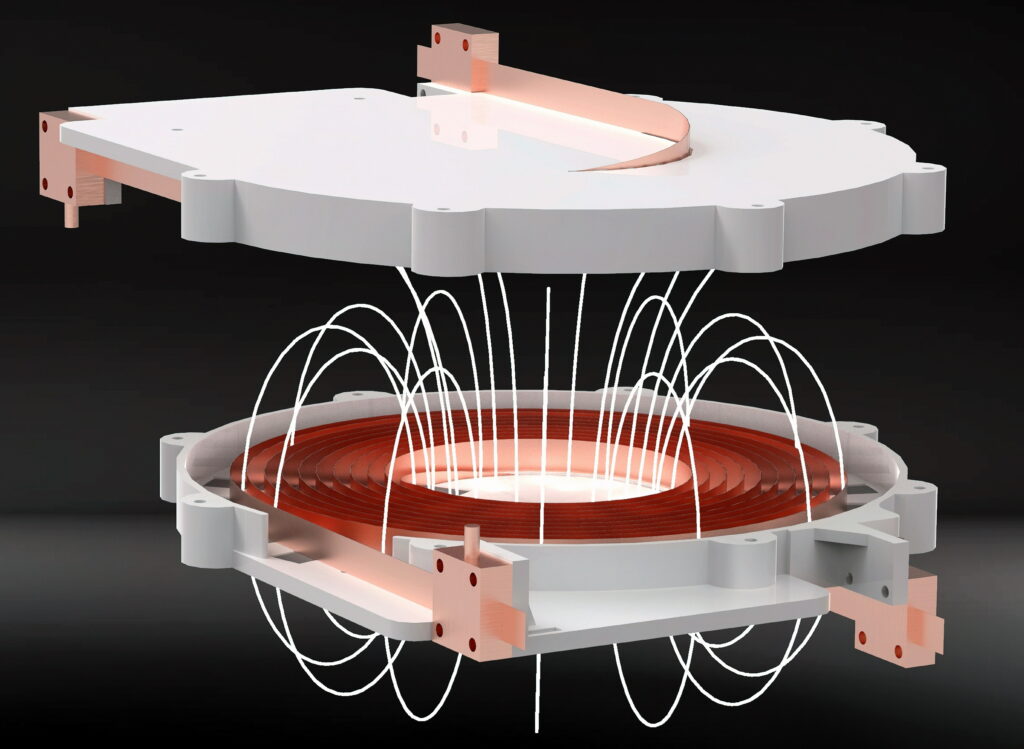

(Image courtesy of Technical University of Munich)

Researchers in Germany have developed a coil with superconducting wires that are capable of transmitting up to 5 kW of power with minimal losses (writes Nick Flaherty).

The team, at the Technical University of Munich, worked with Wurth Elektronik eiSos and superconductor coating specialist Theva Dunnschichttechnik on the design of a coil which they believe could be used for fast charging of electric aircraft.

Superconducting coils are a key area of research, as they have minimal resistance and therefore high-efficiency power transfer. The main problem with superconducting coils is that as the power increases, so do the losses, which causes heating. When the temperature rises, the superconducting properties collapse.

So the researchers have developed a special coil design in which the individual windings of the coil are separated from one another by spacers. This reduces the AC losses in the coil and allows power transmission as high as kilowatts.

This called on the researchers to resolve a fundamental conflict. If they made the distance between the windings of the superconducting coil small, the coil would be very compact, but there would be a danger of superconductivity collapse during operation. Larger separations on the other hand would result in lower power density.

The team chose a coil diameter for their prototype that resulted in a higher power density than is possible in commercially available systems. The aim was to achieve the lowest possible AC resistance in the smallest possible winding space and so compensate for the reduced geometric coupling from the spaces.

The distance between the individual windings was calculated using analytical and numerical simulations. The separation is equal to approximately half the width of the superconductor.

However, even a ‘high temperature’ superconducting coil needs cooling with liquid nitrogen, and the cooling vessels used cannot be made of metal. That is because the walls would heat up considerably in the magnetic field used to transfer the 5 kW of power.

ONLINE PARTNERS