MAHLE Powertrain’s Mike Bassett explains advances in hybrid and EV innovation

Finding the right direction

Mike Bassett, Head of Engineering at MAHLE Powertrain, speaks to Will Gray about hybridisation, EV innovation and why the future of vehicle propulsion has many routes

Mike Bassett leads approximately 180 engineers and technicians tasked with innovating the technology behind MAHLE Powertrain’s advanced propulsion systems. Having initially been schooled in the thermodynamics of ICE engines, his route has followed a fascinating path as the world pivots from petrol, via hybridisation, to a currently EV-focused future.

Accelerating developments in synthetic and zero-carbon fuels, advances in hydrogen fuel cell technologies and continued queries over battery resources, efficiency and range, however, all mean that while electrification might represent the most efficient solution, innovation in the areas of hybridisation, vehicle dynamics and even ICE technology could still be of huge value.

Over the past 18 years, while at MAHLE Powertrain, Bassett has worked with one common focus in all these areas of technology, and he explains: “The projects I really enjoy are the most technically challenging ones, where perceived wisdom breaks down and you go back to the core principles, look in detail at the fundamental workings of things and find out how to improve them.

“Most of the work we do with clients is confidential, but we’ve also done a lot of our own research projects over the years to demonstrate technology, and we’ve achieved innovation in many different areas. Some of our work is on particularly niche applications, and they really do drive some unusual requirements that then make you stop and think.”

During Bassett’s career, priorities have changed from his initial work on innovations to create ICEs that deliver more powerful performance cars to his more current-day work on the creation of hybridisation and battery solutions, which make vehicles more efficient and effective in an era where emissions are taking increased priority.

Back in his PhD days at the University of Manchester Institute of Science and Technology, his work involved modelling the gas dynamics in ICE intake and exhaust systems, and that led him to a job at Lotus Engineering, where he helped develop code that simulated intake and exhaust pressure waves. He also spent time looking at whole-vehicle efficiency and simulating fuel consumption over drive cycles in various vehicles.

At the time, Lotus was developing a Proton Gen 2 hybrid demonstrator vehicle for its parent company, which led Bassett to make his first foray into hybridisation. Working on simulation of the vehicle drive cycle, he defined the specifications and sizes of components across the vehicle’s drivetrain and evaluated how best to use the electrical energy.

The lessons he learned then still serve to this day, because the efficiency of the entire vehicle remains one of the many impactors on the performance and range of all hybrid and electric vehicles, and he explains: “Whole drive cycle analysis gives you an understanding of total vehicle efficiency and how any parasitic losses will really cost you over that cycle.

“Of course, it also varies depending on use case. If you’re driving at high speed, the dominating factor is aerodynamic drag; at low speeds, auxiliary systems, the power of pumps, fans and air conditioning systems really make a big difference to the range. Understanding those different trade-offs is hugely relevant to EVs.”

The move to MAHLE Powertrain

When financial instability led to uncertainty over the future of his role at Lotus Engineering, Bassett made “a sideways move” to join MAHLE Powertrain, working on engine thermodynamic analysis for various customer projects.

Shortly after his move to MAHLE Powertrain, the parent company (MAHLE) instigated a project to develop a Stirling engine for solar power generation. Sitting at the focal point of an 11 m mirror, it used a solar collector to generate 30 kW of power. The project made it to running hardware and was tested using a gas burner on one of MAHLE’s engine test cells before market forces brought it to an end.

“Applying my thermodynamics knowledge to that engine was really quite interesting,” Bassett recalls. “We achieved 42% thermal efficiency, which as far as we know makes it one of the most efficient Stirling engines ever built – but at the time we were developing it, the price of photovoltaics dropped and it became financially less attractive.”

During his first few years, he also began to instil his experience of full-cycle fuel economy analysis into exploring the impact of the company’s engines on vehicle efficiency. This proved to be very valuable in 2010, when the company began research on EV range extenders and formed a hybrid product group. Bassett was placed in charge, and he and his team were tasked to develop a fully functioning C-segment passenger car as a demonstrator vehicle.

“That was a career highlight for me,” he reflects. “It involved developing a range extender unit, putting it in a vehicle and developing the strategy for running it for the best efficiency, while also maintaining good noise, vibration and harshness (NVH) levels. I still look back on that project with fond memories.

“We received a lot of interest from vehicle manufacturers who were considering range extenders. So, we developed the engine in 2010, created the vehicle in 2012 and for the next five years we were still getting regular inquiries about the possibility of buying that engine, but we struggled to turn that into a commercial reality.

“Recently, though, we saw interest rekindled with a Chinese engine manufacturer, and we have literally just finished developing a high-efficiency range extender for them. I was surprised that it didn’t get more traction originally, so it’s good to finally see market pull for that. Sometimes, it just takes time for some of these things to come through.”

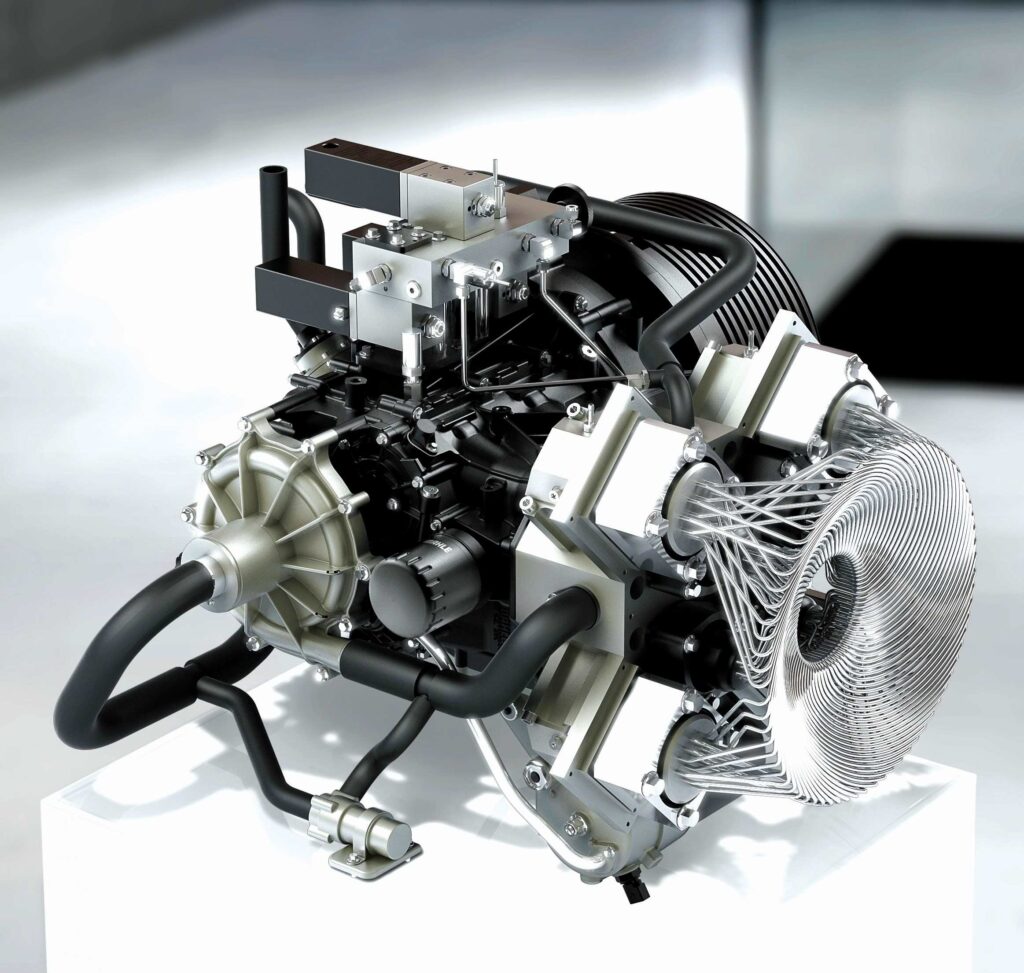

The design that MAHLE Powertrain has developed for the Chinese market is a 60 kW, two-cylinder, turbocharged engine weighing around 80 kg, plus its generator. Very high efficiency is achieved through use of a high compression ratio, low-pressure exhaust gas recirculation and a pre-chamber-based combustion system. Bassett says with that amount of power, the electric car it is supporting can cruise at motorway speeds without depleting the battery, creating a seamless approach to hybridisation.

“The vehicle characteristics are always the same whatever it is doing,” explains Bassett. “You are always driving with the electric motor and because the engine is totally decoupled from the wheels, that enables a more extreme approach to optimising engine efficiency. The extra range capability simply depends on the size of the fuel tank you put in the vehicle.

“The engine achieves a brake thermal efficiency of around 40% with quite a low technology package designed to run on local fuels. So, in terms of CO2 intensity in grammes per kilowatt-hour, it is probably achieving something similar to the Chinese electricity grid. On that basis, it’s not an unreasonable approach, certainly for the time being.”

Exploring innovation

Bassett’s career progression at MAHLE Powertrain led him to become head of research in 2016, a post that he held for six years before moving into his current role as engineering director. During that period, he continued to lead on many innovative projects including traditional hybrids, fast-charging batteries and even fuel cells.

One of the most interesting battery innovation projects was the application of a unique fast-charging lithium-carbon battery produced by Allotrope. The cell has relatively low energy density but extremely high-power density, enabling extremely fast charging whilst being robust enough to charge time and again with minimal deterioration.

The research project analysed the applicability of cell technology to the use case of a pizza delivery moped, and Bassett recalls: “You could put in a decent charge in the space of 30 seconds. So, you could return to the shop, charge while you collected another load of pizzas, then go out on more deliveries. The technology was really interesting and it’s still being developed, so hopefully we’ll see it in an application soon.”

Another bike project, partly funded by the Advanced Propulsion Centre and developed with White Motorcycle Concepts, considered development of an electric version of the Yamaha Tricity bike – the WMC3000e+ – for use by first responders and emergency services. MAHLE Powertrain’s role was to design and produce a bespoke battery pack with a premium placed on charging. The resulting, more conventional, 11 kWh lithium-ion battery delivered a beyond-industry-standard time of 15 minutes for a 20% to 80% charge.

The team also explored fuel cell EVs in a project with Bramble, developing a Renault Kangoo van as a demonstrator. The team developed the balancer plant for the fuel cell stack, a controller and the vehicle integration, and it showcased this approach as a potential solution for certain powertrains that are difficult to electrify.

The company’s work has, on many occasions, been supported by collaborative funding and third-party projects, much of which Bassett helped secure. He believes it is essential that investment in research from governments and innovative companies continues as we push to achieve our net zero goals.

“It helps us to increase the amount of research work that we do, and it certainly alleviates some of the burden of undertaking that type of research,” he explains. “It’s quite challenging for us in the nature of the work we do, because we’re developing skills and capabilities rather than a physical product.

“We offer a service, we don’t manufacture things, and the research funding tends to be targeted toward product development. Even so, having something we can point to and say ‘we’ve got this capability and you can see it in that’ is extremely valuable to us.”

Looking into the future

Bassett’s position as the technical lead at a company offering solutions across the entire vehicle powertrain gives him a strong understanding of industry trends, and MAHLE continues to research and develop ICE, hybrid and electric systems, with the goal of optimising each solution to work more efficiently, economically and with fewer emissions.

So, what does the future of the vehicle powertrain look like? “That’s a really good question and I wish I had a really succinct answer,” smiles Bassett. “It depends on the timeframe. In 2035, the European passenger car market is set to be all EV and there won’t be a place for hybrids, but that path from now to then will be interesting and I think over the next decade we’ll see more range extenders.

“If you look at China, their roadmap still has engines out to 2060. They’re taking massive strides into vehicle electrification – in some cities, all their taxis are electric, and these are cities of 15–20 million people – but then there’s lots of vehicles on the road and it is a country with developing infrastructure, so hybrids will be there for a long time to come.”

Bassett suggests that the advance of plug-in hybrids over range extenders has been driven, in part, by tax breaks that have skewed design specifications in the wrong direction and he explains: “Historically, the platforms the manufacturers had led them down the hybrid route, rather than range extenders, but I think also some early range-extended vehicles didn’t help.

“One particular product used a range extender that was a bit underpowered and if the battery got distressed, it revved at high speed, giving it a bad reputation for NVH. At the same time, plug-in hybrids were pushed onto company car users, but these users also often get free fuel, so they’re not incentivised to plug them in as often as they should.

“It’s all about driving the right behaviour. I think that at the moment, 48 V mild hybridisation, from a cost–benefit perspective, makes great sense. If you were producing a conventional vehicle, that type of solution would give you a 5–10% fuel economy improvement for a relatively modest on-cost. So why wouldn’t you?

“On EVs, there are still range limitations, particularly where there is limited infrastructure and accessibility to charging points isn’t guaranteed, and I think that even with established EV infrastructure, there will be occasions – around busy events – where there are going to be pinch points.

“Range extenders can help that; it’s just a simple difference in thinking. A hybrid is an ICE vehicle with electrification to make it more efficient, but as you get toward the plug-in hybrid end, you start defining which system dominates and you can look more to drive the car electrically. Then, in the case of the range extender, it is just an EV with a generator.”

Improving electrification efficiency

Ultimately, however, the efficiency of electrification and the need for emissions elimination means hybridisation, and range extenders are merely means to an end. When it comes to the future of private transportation, the challenge now is to determine those areas of the powertrain that offer the biggest opportunity for improvements in range and performance.

“I think there’s most scope with the battery,” offers Bassett. “Typical motor efficiencies are already 95% and upwards, and while there are improvements to be found in whole-vehicle efficiency, these are only fractional gains because generally modern vehicle drive systems are already quite efficient and we are now nibbling at the edges.

“The trend for bigger SUVs creates aerodynamic drag and also adds vehicle mass, which increase rolling resistance and directly determine how much energy is required to accelerate the vehicle. When it comes to optimising vehicles, it is all about minimising parasitic power consumption from things like ECUs, pumps or fans that consume power, and maximising regeneration.

“Braking regeneration is already pretty efficient, but wheel motors are quite an interesting technology because they offer packaging advantages but they are quite challenging from a torque delivery perspective. You don’t have any gear ratio between the motor and the wheel, so there will definitely be some developments in motor topology.

“Ultimately, though, the battery is still a large, heavy and expensive part of the vehicle, so there is lots of opportunity for improvement. There are big strides being made in this area, but there are still questions around recycling and how efficiently we can recover the materials out of the battery at end of life. That’s really challenging at the moment.

“I think with some cell technologies, fast charging will also see a big advancement, but the bigger the vehicle, the harder it becomes. Charging in seconds could be realistic for scooters, mopeds, power tools, those kinds of things, but once we get to trucks and buses it becomes more and more challenging due to the power levels involved to recharge large packs quickly.”

The resource question around the use of batteries as a long-term solution remains a big question for Bassett. His efforts are clearly focused on a desire to reduce emissions across the board, using whatever means available – and there is now an ever-increasing range of options on the table.

Bassett sees a place for many different propulsion technologies in the vehicles of the future and his work at MAHLE Powertrain continues to explore all avenues. “We have to be open to these different technologies and assess them all in an even way,” he concludes. “We shouldn’t overlook any opportunities to reduce environmental impact.

“Renewable fuels and electricity are both mechanisms for transporting energy, but with renewable fuel, there’s a whole conversion chain and losses there. So, if you are using a renewable fuel, why wouldn’t you hybridise as well? There is also a space for fuel cells and hydrogen ICEs in cases where the amount of energy and the duty cycle just don’t fit.

“Several companies are looking at hydrogen for the off-highway heavy duty sector, for example, and I think we will also see that for machines like combine harvesters, which are used intensively in a remote location for a few weeks of the year, as well as the marine and aviation sectors. Ultimately, when you put it simply, what you are after is the most efficient use of renewable energy to propel your vehicle – whatever that solution might be.”

Click here to read the latest issue of E-Mobility Engineering.

ONLINE PARTNERS