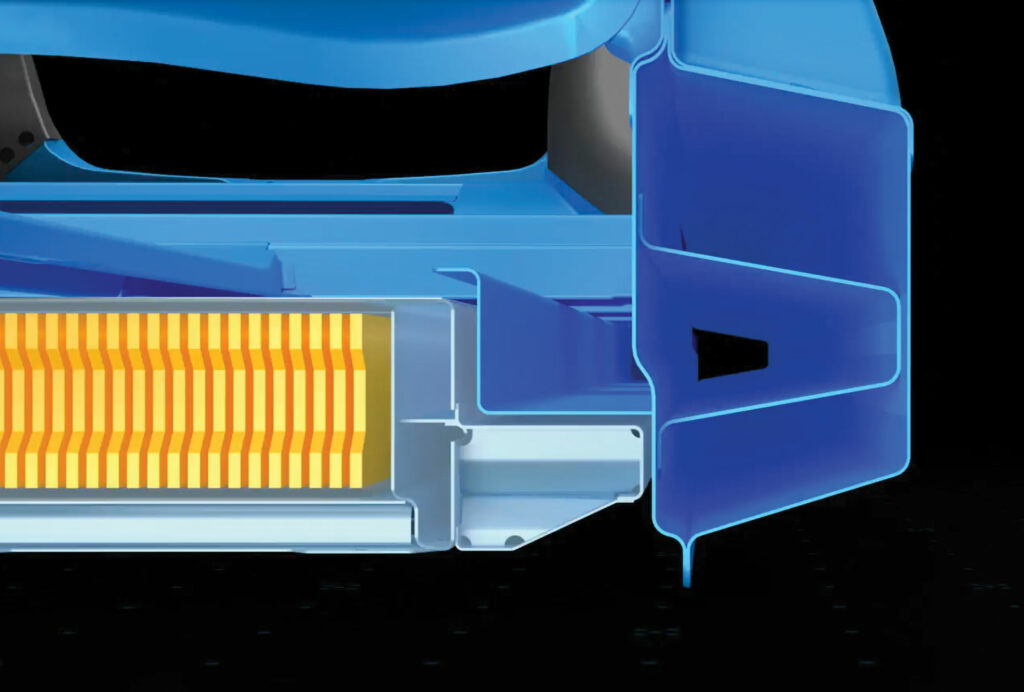

Battery pack materials

(Image courtesy of Kautex Textron)

Lightweighting the battery pack

New materials are fighting to reduce the weight of the battery enclosure in an EV, as Nick Flaherty explains

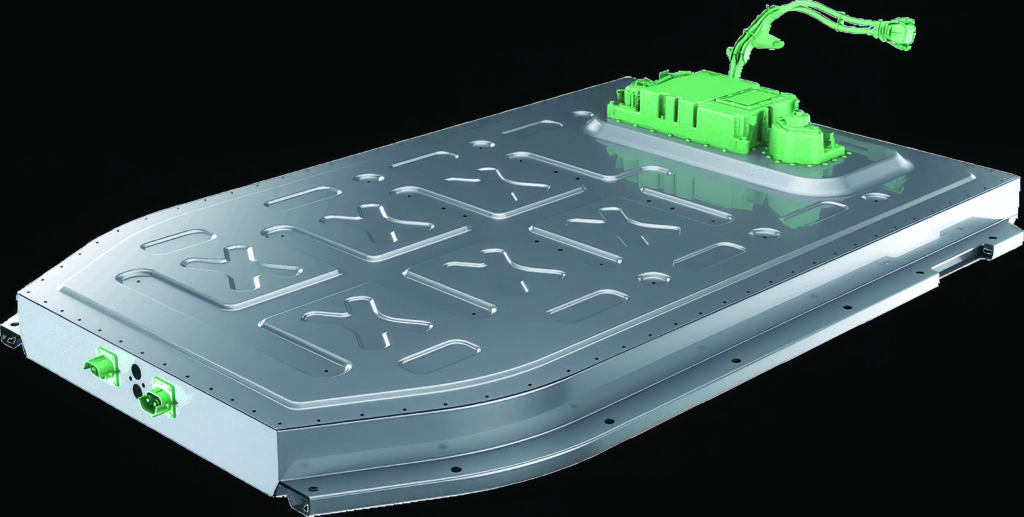

Around 80% of battery pack enclosures today are constructed from aluminium, with the rest built from steel. A new generation of materials is being explored for reduction of the weight of the pack, which can be considerable. A typical battery pack can weigh 500 kg, with 100 kg of that wrapped up in enclosure materials.

At the same time, there are increasing requirements for fire protection and structural performance to be part of the vehicle and for protection to be offered against foreign objects. The pack material also increasingly has to be sustainable, reducing the overall carbon footprint of the vehicle, and it needs to be recycled in the end-of-life process of the vehicle to meet the latest European legislation.

All of this must be achieved while meeting the crush and crash safety requirements to protect the battery and by hitting cost targets because car makers expect the battery pack to account for 30–50% of the vehicle cost. This is pitting the latest recycled aluminium materials against high silicon steel and a new generation of composite thermoplastic materials that can now be used to produce large components such as lids and bottom panels quickly and easily.

Materials

Aluminium enclosures are lightweight and corrosion-resistant and can be extruded into complex cooling channel designs with good thermal conductivity for passive/active cooling. Adding existing aluminium into virgin material significantly reduces the carbon footprint without impacting performance.

However, the lower stiffness than that of steel means reinforcement might be needed for crash loads, both fatigue and crack propagation can be a concern if not designed carefully, and the material is more expensive than steel for equivalent strength.

Steel enclosures have high strength and excellent crash protection with reasonable cost-effectiveness for structural parts, and they are easy to weld and form into rigid enclosures. A high silicon content reduces the carbon footprint and allows thinner structures to compensate for the fact that steel is heavier than aluminium. Steel also has lower thermal conductivity, which reduces passive heat spreading, but it is susceptible to corrosion unless treated or coated.

Composite materials, particularly thermoplastics, can have a very high strength-to-weight ratio, are corrosion-proof and can be moulded into complex shapes with excellent fatigue resistance. But they also have poor thermal conductivity unless hybridised with conductive inserts. However, despite these issues and irrespective of their high cost and more complex manufacturing process, composites have been used in high-end designs and can now be used in mid- and even low-end designs.

Steel

Steel has been fighting back against aluminium. With the same crash safety performance and roughly the same weight, the high silicon steel design for a 70 kWh battery is up to 50% cheaper to fabricate compared with an aluminium alternative.

This was the finding of analysis based on a scenario of 200,000 vehicles/year over a period of seven years. It included material and manufacturing costs, tooling investments for parts manufacture, and body-in-white production including leak testing and corrosion protection.

The melting point of a 0.8 mm sheet of steel is 1410 C. In fire tests, the temperature of the steel battery housing cover barely exceeds 1000 C, even after 20 minutes, demonstrating the impressive safety reserves of steel. By contrast, a 1.1 mm thick sheet of aluminium reaches its melting point of 610 C after just 15 seconds in a fire test; after 30 seconds the material collapses.

High silicon content allows thinner material with the same strength to be used to make slim and thin-walled crash structures, saving packaging space and freeing up room for large batteries. Battery housing with multi-chamber profiles made from high-strength steels can support very high loads in side-on collisions and prevent contact being made between the housing parts and battery modules.

Life cycle assessments show that steel is more sustainable, with up to two thirds lower greenhouse gas emissions in the production of a steel battery housing compared with those associated with an aluminium design.

(Image courtesy of Windform/CS Energica)

Aluminium

However, aluminium producers point out that recycling aluminium uses only 5% of the energy required for primary aluminium production and reduces CO2 emissions by more than 90%.

Modern manufacturing techniques, such as hot stamping and adhesive bonding, enable significant weight reductions with aluminium without substantial cost increases. As less material is required to achieve the same structural integrity, the reduction in material usage can offset the per-unit cost of aluminium compared with that of steel, leading to overall cost savings. Additionally, lighter vehicles benefit from secondary weight savings. For instance, replacing 400 kg of steel with 240 kg of aluminium results in a primary weight reduction of 160 kg, which can lead to an additional 40–60 kg reduction in other components, such as brakes and suspension systems.

Beyond production scrap, aluminium can be recovered from end-of-life vehicle recycling initiatives. Through scrap sorting and segregation, specific aluminium alloys can be captured from decommissioned vehicles to feed back into the production process.

A lighter aluminium battery pack means a car can use smaller parts, including brakes, suspension parts, batteries and motors, yet achieve the same acceleration, performance and range with lower emissions.

Aluminium also absorbs more energy that steel per kilogram. Therefore, a lightweight aluminium battery pack can be safer for the occupant than a comparable steel-based vehicle. When kinetic energy is absorbed in a controlled manner, aluminium means that vehicle occupants will be better protected from intrusion.

Automotive grades of aluminium alloys are also less prone to corrosion because of the self-healing, protective barrier that forms in milliseconds when they are cracked, dented or deformed. Unlike automotive steel grades, which are inherently susceptible to rust and rely on protective systems for durability, aluminium does not need a protective coating, even in severe environments.

Steel is recyclable but needs higher processing temperatures of 1400 C, whereas aluminium melts at less than half that temperature (650 C). Typically, vehicles are manufactured with 600 kg or less of aluminium for every metric ton of steel; therefore, the energy savings associated with aluminium are noteworthy.

(Image courtesy of SABIC)

3D printing

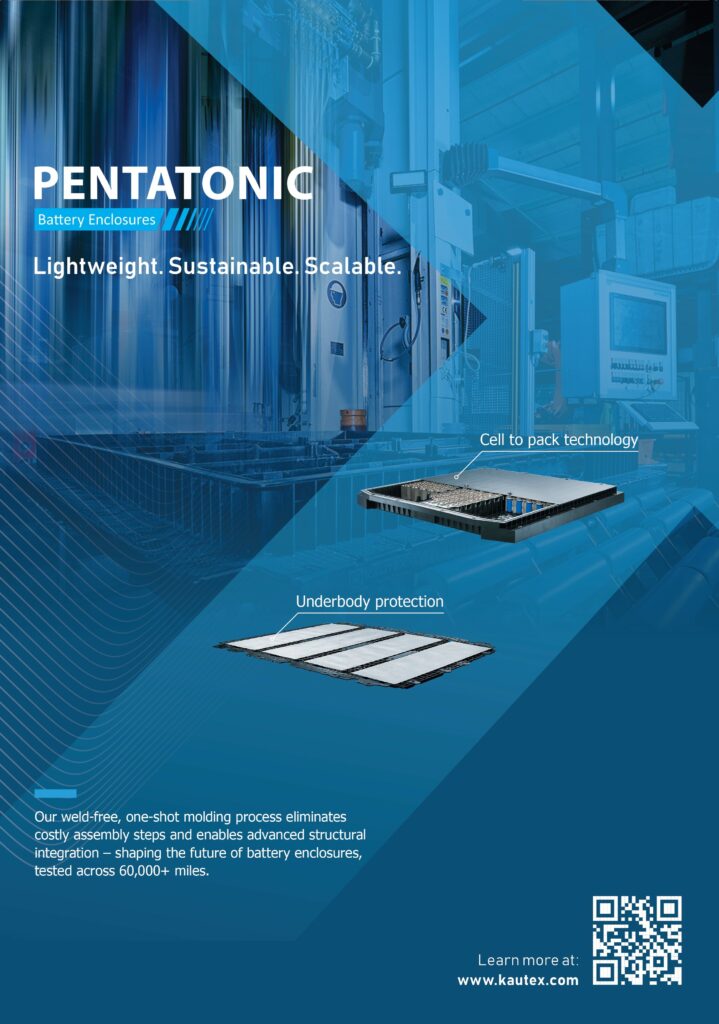

Carbon reinforced plastic (CRP) has also been used for the battery housing of an electric motorcycle using a multi-phase approach combining 3D printing, CNC machining and casting to optimise the thermal management, safety and reliability.

The process combined CNC machining and sand casting with a CRP material to create a prototype via 3D printing. This was then used to create the aluminium casing for production.

The unit had to perform under acceleration and fast charging, while remaining electrically safe, thermally stable, mechanically strong and ready for EMC testing. It also had to be brought into series production on a tight schedule.

The development began with a full-scale prototype produced by selective laser sintering using a glass fibre-reinforced polyamide. The high temperature resistance and electrical insulation allowed direct r&d and testing on a working component.

The 3D build volume of 550 x 550 x 450 mm allows the entire prototype to be printed in one piece, including the central septum. This is an aluminium plate that directs airflow to prevent battery overheating during acceleration or fast charging.

The second step was rapid casting of the battery housing in aluminium, followed by CNC machining. The structure – made of two shells – had to maintain dimensional accuracy, resist distortion and be safe in case of motorcycle impact.

For production, the process evolved into traditional sand casting, using the same aluminium alloy. The refinements made during the prototyping phase meant that no rework or delays occurred.

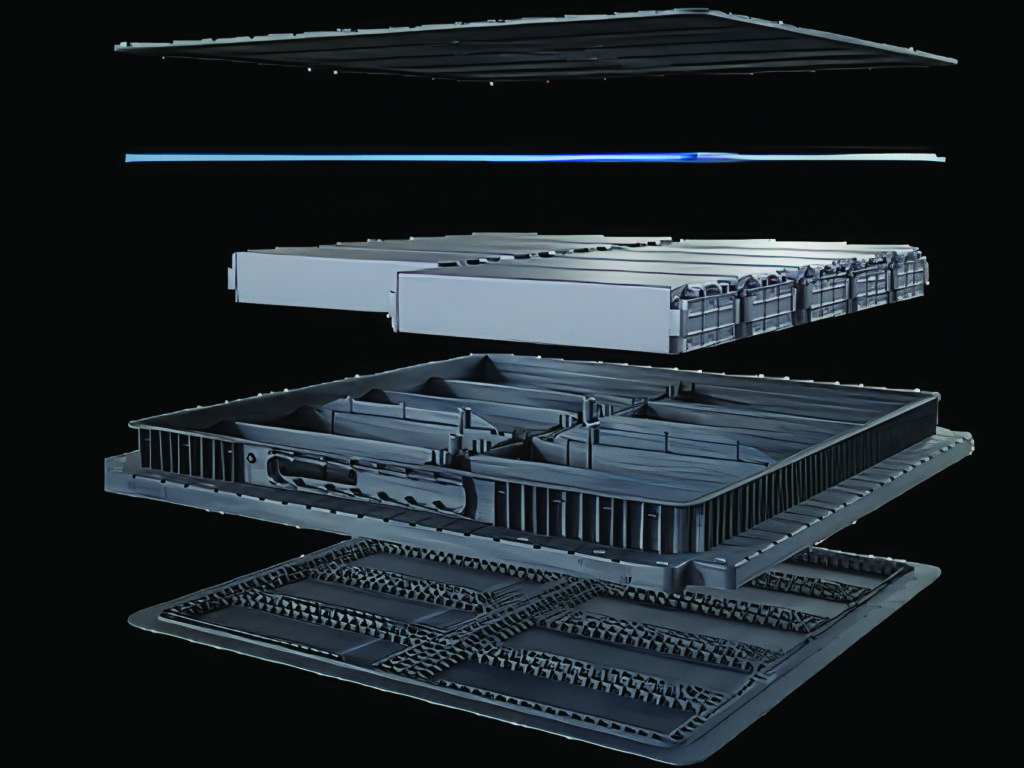

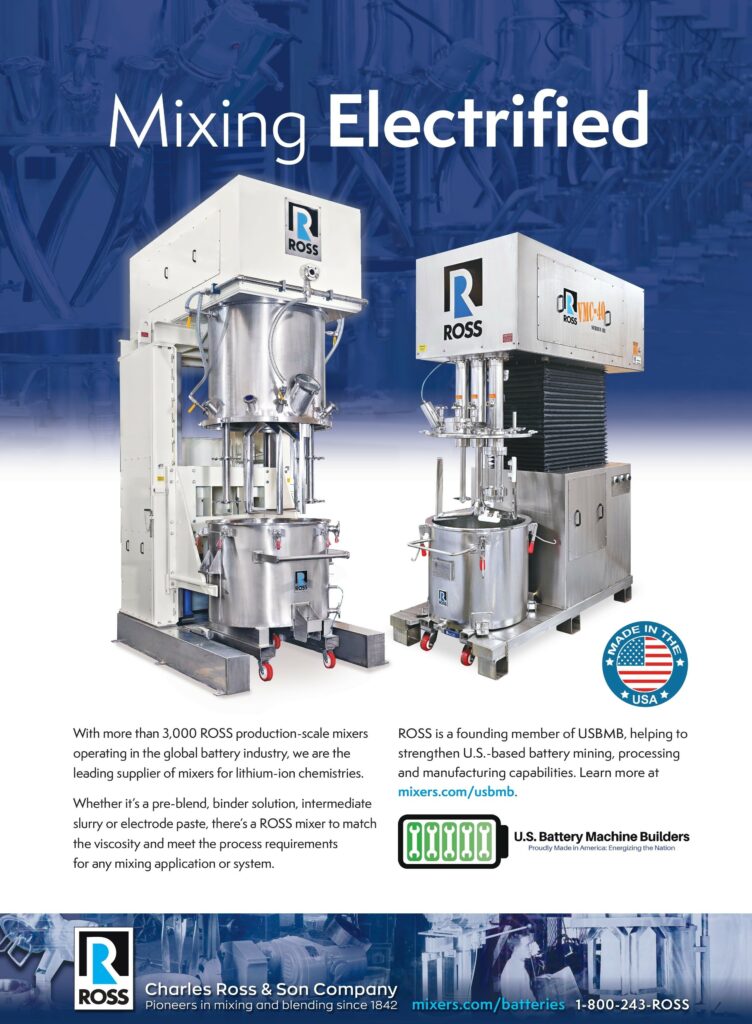

Thermoplastics

Thermoplastics present a very interesting option for battery enclosures owing to their unique combination of mechanical, thermal and environmental advantages. One of the benefits is the lightweight nature paired with a strength-to-weight ratio greater than that of other approaches. By overcoming traditional cost and processing barriers, the latest thermoplastic casings offer manufacturers a scalable alternative to metal and thermoset materials.

However, this requires expertise in materials, tool design and process optimisation, in addition to materials and process modelling.

While thermoplastics have long been used in manufacturing, the cost, complexity and processing challenges have limited their application to large components. Improvements in advanced materials, coupled with the machinery, moulding, tooling design and processing expertise across the value chain, make thermoplastic moulding of large parts more feasible for more components, and battery casings and trays are the first areas to exploit such technology.

Using thermoplastic moulding allows for cost and process efficiency by using competitive tooling, consolidating parts and simplifying manufacturing, post-processing and assembly steps. It has faster injection moulding cycle times compared with metal casting or thermoset processing, as well as greater design freedom to achieve more complex geometries and functional integration that are difficult with metal stamping or casting. This enables simplified product architecture with better designs for disassembly, sorting and recycling as well as weight and mass reduction while meeting strength and stiffness requirements.

The strength in thermoplastic materials is typically achieved using reinforcing agents such as glass fibres or talc, combined with thermoplastic polymers such as PP, PC, PBT, PET or blends of these. This combination delivers the desired strength at the material level before being moulded into large battery enclosures.

For fire retardancy, various flame-retardant ingredients are integrated into the thermoplastic compounds to meet specific safety requirements. While the exact formulations are proprietary, these include halogenated, non-halogenated, intumescent and options for non-intentionally added PFAS (per- and polyfluoroalkyl substances). These are selected based on resin type and customer requirements.Some suppliers use a database of materials through internal research and extensive prototyping of large battery components. To enable large-scale production, materials with a low viscosity or high flow are needed to fill the larger dimensions using existing injection moulding equipment in the supply chain.

A key advantage of thermoplastics is that the materials can be optimised for the process conditions, allowing these components to be manufactured without significant new capital investment. A large battery enclosure prototype demonstrates proof-of-concept across multiple manufacturing methods for plastics, including injection moulding, compression moulding and thermoforming.

Using the thermoplastic approach cuts weight by 20% versus that of an all-aluminium design.

Thermoplastic enclosures have been proven in both virtual and physical impact tests to meet and exceed customer requirements, even in the critical side-pole crash scenario.

The high impact toughness makes the material resilient against mechanical stress and external forces. This is particularly valuable in crash scenarios or harsh operating environments, where structural integrity must be maintained.

Another key advantage is the design freedom and flexibility thermoplastics offer. Unlike metals, they allow for the creation of complex geometries and integrated features in a single moulded piece. This not only simplifies assembly but also reduces part count and associated costs. For example, thermoplastics can achieve tight radii and intricate contours that are difficult or impossible to replicate with metal stamping or machining.

Additionally, thermoplastics are non-corroding, which enhances the longevity of battery enclosures and reduces maintenance needs. Their inherent electrical and thermal insulation properties also contribute to safer battery designs by minimising the risk of short circuits and thermal runaway.

From a sustainability perspective, thermoplastics support a reduced CO2 footprint through lighter weight and recyclability. Many formulations are compatible with closed-loop recycling systems, aligning with broader environmental goals and regulations.

Thermoplastics also enable fast cycle times – often under 120 seconds – and high-volume production within a lean manufacturing footprint. This makes such materials suitable for scalable automotive applications where speed, efficiency and repeatability are essential.

Material selection

The selection of PP or PA resins for enclosure material is derived from a system-level approach that must balance structural and functional performance, material availability, global supply, CO2 footprint and system cost. In many cases, the resins are supplemented with up to 50% glass fibre to provide a robust material for battery enclosure design.

One of the key benefits of composites is the ability to integrate components during the one-step moulding process to address areas of high structural loading. Endless or continuous glass fibre profiles can be integrated as local reinforcements. During the moulding process, these profiles are heated to melting temperature and placed within the mould, creating a bond with the base resin material.

Glass fibre plays a crucial role in enhancing the structural integrity and performance of battery enclosures without compromising on cost and sustainability for high-volume automotive applications. At the same time, glass fibre improves the thermal stability, particularly in the case of thermal runaway events. Extensive thermal runaway testing of the materials includes a variety of cells and cell formats with characterisation of specific cell thermal runaway events, including temperature, pressure and gas composition. These data ensure that thermoplastic material systems can meet and exceed legal and customer requirements for thermal runaway protection.

The process of evaluating the materials with the various additives includes quasistatic and dynamic coupon level tests, including failure calibration, to develop basic material ‘cards’. To ensure good correlation at a full system level and achieve the highest material card level, called ML6, system-level testing with both quasistatic and dynamic loads, including failure calibration, is necessary.

Use of composite material not only has to consider strength but also other factors.

Electromagnetic shielding capability is typically lacking in composites, but multiple additives have been developed that can be integrated into the moulding process or assembled in downline processes. One in-mould example is an aluminium film that can be draped within the mould and formed/moulded to the final shape. Solutions like this have been tested to meet typical automotive electromagnetic interference (EMI) standards such as CISPR A4.

(Image courtesy of ThyssenKrupp)

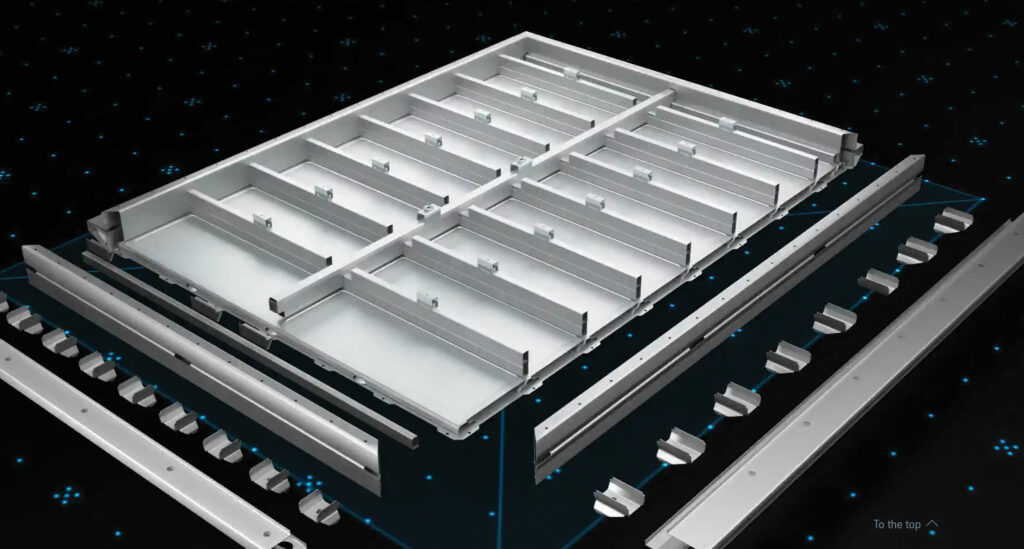

IM versus CM

The choice between injection moulding (IM) and compression moulding (CM) depends on specific project requirements and whether there are impact requirements such as bottom bollard, vehicle crash and crush.

The integration of steel and aluminium sheets, strips and beams is possible and already in use in mass production applications today. This makes the designs highly customisable to specific requirements while providing a sustainability advantage because the carbon footprint of the base material is over half that of aluminium, and it is significantly lighter with a 30% reduction in weight. It also allows for tight radii and inherent leak tightness owing to the one-shot process, which means that there are no bad welds that could leak.

Using a one-shot process allows for integration of multiple components into the design, reducing the need for secondary process steps. This reduces costs by reducing the bill of materials and amount of equipment required.

The carbon footprint also drives other choices. Some providers chose not to use duroplastic because of its high footprint. This is a type of thermosetting plastic, similar to Bakelite, made from a mixture of synthetic resin and a renewable resource like cellulose or cotton waste that hardens permanently under heat and pressure.

Instead, up to 50% recycled plastic material can be used with up to 20% biomass such as cellulose to reduce the carbon footprint and help to meet the end-of-life vehicle directive from the European Commission. This requires at least 25% recycled plastic materials in a newly produced vehicle.

The base materials are sourced from suppliers with long-term contracts to ensure global coverage as well as sufficient availability. Sources range from post-consumer recycled (PCR) materials, for example, with granulate recycled from fishing nets discarded in the ocean.

Investigation

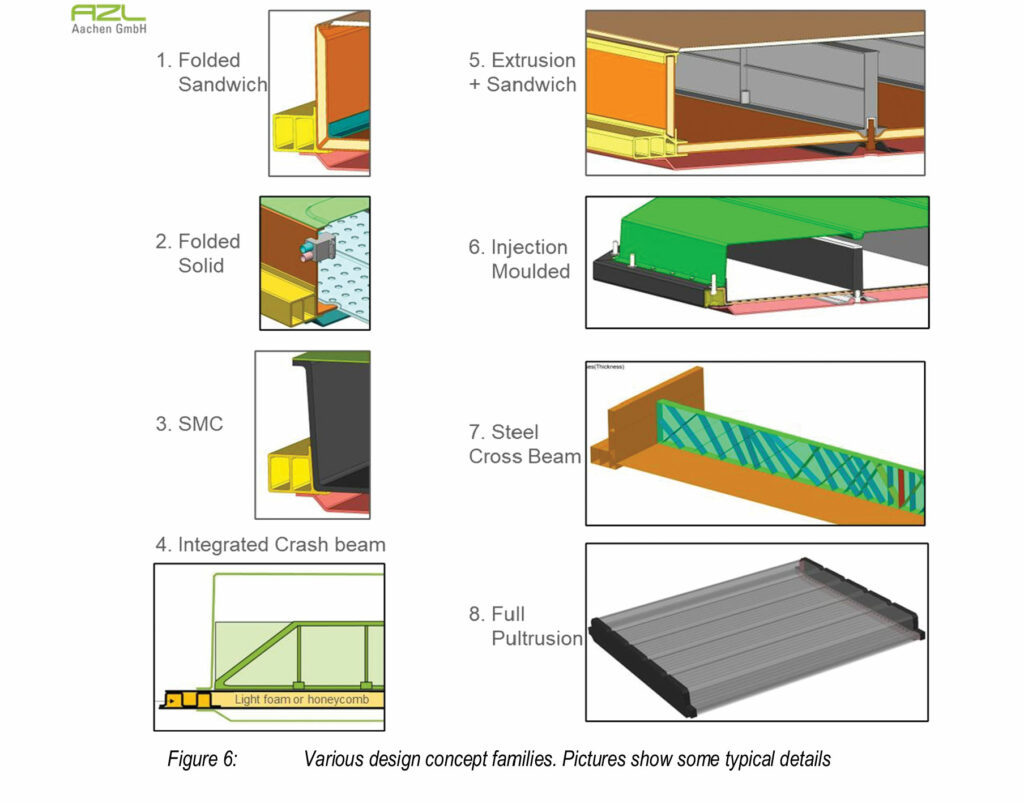

To explore the different material options for battery enclosures, a consortium in Germany investigated several alternative multi-materials.

Alternative materials included both thermoset and thermoplastic materials, solid laminate or sandwich designs, short fibre overmoulded structures as well as steel and aluminium, and combinations of all these materials were compared with a reference welded aluminium battery casing.

All relevant load cases were considered in the CAE analysis, as defined by safety regulations, in combination with specific OEM requirements. In total 20 different multi-material concepts were optimised on weight and cost and then compared with the aluminium reference design.

All the production steps were cost-modelled in detail to obtain reliable cost estimates for each variant. Consequently, each concept resulted in different weight savings of up to 36% and cost savings of up to approximately 20%.

Weight is key because an average 70 kWh battery pack can weigh as much as 500 kg with the casing weighing as much as 100 kg, including bottom protection or skid plates.

Eight design families were developed. The material choices were varied in each family, and CAE optimisation analysis was performed to find the lightest possible designs. Some components could be considered individually in the optimisation process, such as the lid, which could be applied to many different box concepts. The same applies to the bottom protection plate.

Each design was also developed to comply with EMI shielding, ranging from the simple application of aluminium foils or using aluminium-coated glass fibres as an integral layer in a composite layup.

Tests are still underway on fire resistance, but researchers expect composites to compare favourably in comparison with aluminium because a five-minute thermal runaway flame exposure will melt a hole in aluminium quite quickly, while long or continuous fibre material will survive much better.

Many concepts, both in thermoset and thermoplastic material, were shown to be cheaper than the aluminium reference part. This has partly to do with the high cost of aluminium, such as in the form of extrusions, while glass fibres are still relatively cheap. A key finding was that the choice of the right alternative geometries has much more impact on weight saving than using high modulus materials. For example, for the same glass composite material, deep bead stiffeners can reduce the weight of a lid from 14 to 5 kg, while maintaining the same stiffness. High modulus materials will also reduce weight but typically at extra cost. For relatively flat components, such as the lid, a sandwich solution can also be very light but will require a few millimetres extra height, which in turn will reduce the available space for battery modules in a given battery pack design space below the vehicle.

The most important conclusion is, however, that there are many opportunities to save both cost and weight at the same time, and even when using various material systems.

Sandwich constructions typically result in lighter designs while taking up more space. These yielded typically about 5% less internal space for battery modules. Whether that may be an issue depends on the particular car design, and the magnitude may also vary when considering more detailed requirements regarding thermal insulation, noise, vibration and harshness (NVH) and other issues.

An advantage of the sandwich is the better thermal isolation, which may have advantages in battery performance by keeping cell temperatures at a more desired level when the car is parked overnight in winter, but also in fire resistance and heat shielding during a thermal runaway event.

Despite the predicted weight and cost advantages for various multi-material concepts, today’s battery pack structures are predominantly made from aluminium and/or steel.

As a first step, OEMs have been replacing the less-complex components, such as the lid and bottom protection plate – parts that don’t affect the battery pack internal design very much. These are low-risk parts during the development phase of the complete battery pack, and it is expected that experience with composite solutions in lids and protection plates will promote further use for more structural parts in future.

Conclusion

Taking advantage of new geometries enabled by composite materials can be a benefit to designers of e-mobility systems, but this must be supported by a manufacturing systems approach. The design and manufacturing guidelines need to be coupled with a rigorous design review process that can drive zero scrap and zero downtime through close collaboration between the design and manufacturing teams. Collecting real-time machine data prevents breakdowns and enhances uptime. By linking this data-lake information with machine learning, product performance specification moves toward predictive part quality. This enables the production process to deliver the optimal battery enclosure.

Acknowledgements

With thanks to Boris Meisterjahn at Kautex Textron, Sami Al-Osaim at SABIC, Daniel Kern at Novelis and Warden Schijve at AZL, Aachen.

Some suppliers of materials for EV battery enclosures

Steel & Aluminium

Constellium

Hydro

Magna International

Novelis

Outokumpu

Speira

ThyssenKrupp Steel

Thermoplastics and composites

Celanese

Covestro

Kautex Textron

Mitsubishi Chemical Group

Nexeo Plastics

SABIC

SGL Carbon

Solvay

Teijin Automotive

Windform

Click here to read the latest issue of E-Mobility Engineering.

ONLINE PARTNERS