Scansonic’s laser welding optics enhance precision in EV battery enclosure manufacturing

(Image courtesy of Scansonic)

Laser welding is taking on an increasingly critical role in the series production of battery enclosures for electric vehicles as vehicle manufacturers accelerate the transition to fully electric drive systems. With the mechanical sensitivity of lithium-ion batteries and the structural complexity of enclosure assemblies, welding technologies must deliver high repeatability, precision and strength while maintaining short cycle times and consistent quality under mass production conditions.

The enclosure performs several key functions: it ensures mechanical protection, contributes to crash safety, manages thermal loads and keeps out moisture. As the enclosure is typically integrated into the underbody structure, its rigidity directly influences both safety and handling. Weight remains an equally decisive factor, leading most OEMs to adopt aluminium as the preferred material. Aluminium-magnesium-silicon alloys from the 6000 series are frequently specified for their favourable strength-to-weight ratios, but their susceptibility to hot cracking creates added challenges for joining processes.

Laser welding offers clear advantages over traditional arc-based technologies in this context. With its focused energy input, the process achieves high travel speeds with minimal distortion, enabling precise and repeatable seams. The ability to localise heat reduces thermal deformation, thereby simplifying overall assembly tolerances and enhancing dimensional stability. However, one longstanding limitation has been the lack of optics suitable for every welding position inside complex battery housings, forcing manufacturers to rely on mixed process lines that compromise throughput.

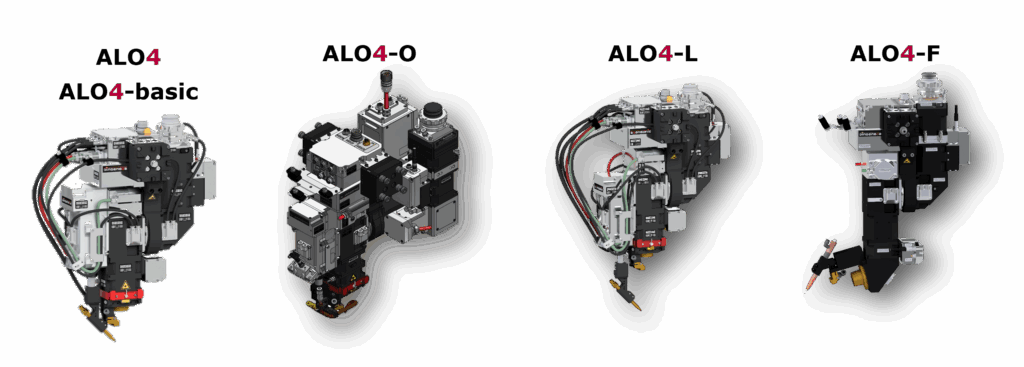

To address these challenges, Scansonic has developed the ALO4 series of laser welding optics, engineered specifically for the production requirements of battery enclosures. The system integrates tactile seam tracking and wire feed to maintain alignment accuracy and stabilise the welding process. The added filler material strengthens the joint and provides crack-preventing support for aluminium alloys prone to hot cracking. Gaps up to one third of the material thickness can be bridged reliably, ensuring consistent seam integrity even in the presence of component tolerances.

For applications with larger joint gaps, the ALO4-O variant incorporates programmable beam oscillation using two synchronised scanner axes operating at up to 1,000 Hz. Oscillation amplitude, frequency and waveform can be freely configured, allowing the molten pool to incorporate additional material from the upper sheet together with the filler wire. This enables gap compensation of up to 50% of sheet thickness, while the oscillating beam produces a wider weld seam with reduced overall heat input — particularly advantageous for thicker cover sheets on enclosure lids.

Geometrically constrained areas within the battery pack call for additional mechanical reach and flexibility. The ALO4-L optic extends the working distance by roughly 70 mm to access deeper weld positions inside the housing. For vertical seams in enclosure corners, the ALO4-F version employs an additional 115° deflection mirror, allowing the laser beam to reach weld seams that are otherwise inaccessible.

All optics within the ALO4 family use a shared control architecture that detects which variant is connected and automatically loads the appropriate parameters, simplifying changeovers and ensuring process consistency. The standardised design reduces maintenance requirements and streamlines the management of spare parts. Compatibility with all commonly available industrial laser sources further improves integration into existing production environments. Scansonic also supplies complementary components, including wire feeders from Dinse and laser sources from Brightlight Laser Systems, providing manufacturers with a complete, harmonised welding solution from a single supplier.

Each version of the ALO4 series is available with Scansonic’s SCeye process monitoring system, which supports full documentation and real-time quality evaluation. Using AI-based detection algorithms, the system identifies pores and spatter from the melt pool while continuously recording process and machine parameters. The resulting datasets form the basis for automated quality assurance and traceable production control – essential attributes for the large-scale manufacture of EV battery systems where safety and reliability are non-negotiable.

Click here to read the latest issue of E-Mobility Engineering.

ONLINE PARTNERS