Kindred Motorworks EV Bronco

(All images courtesy of Kindred Motorworks)

Bronco goes electric

Kindred Motorworks has reimagined the legendary Ford Bronco as an electric icon for the 21st century, modifying this popular classic from the frame up to create a machine with performance streets ahead of the original, reveals Will Gray

Few vehicles define the classic ‘American dream’ more than the Ford Bronco, a 1960s icon with rugged charisma that became a symbol of outdoor freedom, capability and off-road grit. Its boxy big-wheeled looks are legendary, but its gas-guzzling heritage is no fit with modern sustainability – precisely why Kindred Motorworks gave it an overhaul.

The outcome is a machine that preserves the soul of the original Bronco while eliminating well-known flaws such as leaky engines, unreliable components and outdated handling. In their place are dual electric motors, regenerative braking, modern suspension systems and cutting-edge thermal management.

The San Francisco firm is one of a growing number of businesses in the classic electrification game, but the employment of a sophisticated Manufacturing Execution System (MES) for mapping and documentation has made their development process – for the Bronco and a growing number of other reimagined classics – similar to that of an OEM vehicle.

The approach is the brainchild of software entrepreneur Rob Howard, who developed the plan while travelling with his family and pondering his next business move following the sale of his second company. Having restored cars in his garage for years, he came up with the idea of using software to perfect his passion.

Howard’s focus was on developing a process to reliably and repeatably refurbish petrol-powered classics and the Bronco was one of three vehicles initially chosen to develop at a prototype stage, alongside a VW bus and a Chevrolet Camaro – although the latter was later dropped from the schedule.

The company’s first prototype electric powertrain was fitted not to a Bronco but to a 1964 VW Bus and Seth Friesen – who was originally brought in as a contractor to oversee its development and is now director of EV operations – recalls: “It was a crusty old panel bus and it took us two or three months to put it together as a test vehicle.

“The EV system was just motors and batteries, really basic, and it was incredibly fast and dangerous! It had no interior but it was a good proof of concept. Rob showed it to some investors and it was so unique it got their attention. We then built another bus with a proper interior and all the systems as an early show car.”

As development continued, the team put in 25,000 hours of EV-specific r&d, building and testing three prototypes and advancing the sophistication of their control systems into a second-generation platform. At the same time, the company had been developing its MES approach for the petrol-powered Bronco.

When the first petrol Bronco rolled off the line, every nut, bolt, mechanical and electrical component, colour, finish and material had been specified and refined, and everything was in place to scale-up production of that model, rather than the VW Bus – therefore, the Bronco got the nod, and Friesen and the team set about adapting it for the EV drivetrain.

Efficiency in development

The MES production process mapped the genome of the original Bronco, split it into 100-150 different subsystems and created detailed step-by-step instructions to build Kindred’s much-improved version, with information on part sources to screw sizes, and even YouTube videos to enable any technician to come straight in and pick up the job.

Friesen explains: “It’s relatively easy to build a one-off prototype, but we’re not wanting to just build one at a time, we’re wanting to design cars to be built over and over again. That’s a different mindset and a different engineering approach, and that is where the technology and software come into play to create a scalable solution.

“Managing labour and having the supply chain down is important so we can get parts when we need them, and a major part of that comes from laying out and documenting that whole process for the build from start to finish. A ton of our time initially was spent writing all the extremely detailed work instructions for every part of the manufacturing process.”

The Bronco is well known as a sturdy beast and, having originally been used as a low-cost labour vehicle, plenty of donor cars exist. Their typical employment as farm vehicles and heavy-duty workhorses, however, means that many of those examples are not in good enough condition to refurbish.

Consequently, the company made the decision to strip almost everything from the original car and rebuild from the ground up. In fact, the need for precision in the manufacturing process means that pretty much the only part of the original vehicle left is the stock frame, which is what allows the car to retain its original VIN number.

“We’re unique in building up these vehicles pretty much from scratch,” explains Friesen. “We use completely new sheet metal and assemble that all in-house, and that means we restore a lot of cars that typical automotive restoration shops or individuals don’t want to restore because their bodies are rusted or damaged. We’re really just after a frame.”

Once a donor car comes into the shop, it is given a full strip down, disassembled and the frame prepped for the process. Every vehicle is then rebuilt from the ground up to meet stringent design, performance and safety requirements, with the aim of creating a very different result to a typical restoration or EV conversion.

The consistent and repeatable approach, however, does not mean that all EV Broncos are the same. The car is available in different colours, with two package options: Heritage and Trail. Keeping to that strict formula enables the team to keep costs down, maintain efficiency and get more Broncos through the production line.

Electric drive

Kindred’s EV Bronco looks just like its gas-guzzling equivalent from the outside – boxy, bold and off-road ready. But beneath the new steel skin is a fully modern machine that has been innovatively engineered to fit a variety of high-tech systems onto a frame that was never originally designed to carry it.

To create the 4WD drivetrain, the company opted for a pair of Cascadia Motion IDM 190 motors located front and rear. Manufactured in the US, these units are familiar to the EV conversion world and come as a well-packaged integrated unit containing a motor, gearbox and inverter all in one.

Each of the units is mounted on three vibration-isolating bushings to minimise noise, vibration and harshness and extend component life. Additional sound insulation in the chassis further reduces motor and inverter whine, although some wind noise remains because of the design of the Bronco’s body.

The twin motors run on a single high-voltage (HV) bus with independent operation, and each unit features its own fault detection system, processed by the central vehicle control unit, which issues torque and direction commands without synchronising motor speeds. This architecture offers both simplicity and fault tolerance.

Each unit is paired with a fixed gear reduction ratio of 8.28:1, which would typically be too high for vehicles with 32 in tyres but works effectively in this case owing to the ample torque output. It ensures optimal torque delivery during low-speed off-road manoeuvres and maintains peak motor efficiency around 45 mph – a sweet spot aligned to average usage patterns.

Individual CV axles connect the motors to the wheels, replacing the original solid axles and creating the opportunity for improved suspension geometry and handling. Wavetrac limited-slip differentials (LSDs) are integrated to assist with traction, and while there is no mechanical or electronic torque vectoring between front and rear, they ensure consistent traction.

This all delivers a flat torque curve from 0 to 60 mph with a fixed torque distribution of 30% to the front and 70% to the rear. These specifications were chosen deliberately to deliver brisk acceleration and predictable handling characteristics both on the road and on challenging off-road terrain, with immediate availability of maximum torque, even at zero rpm.

Battery packaging

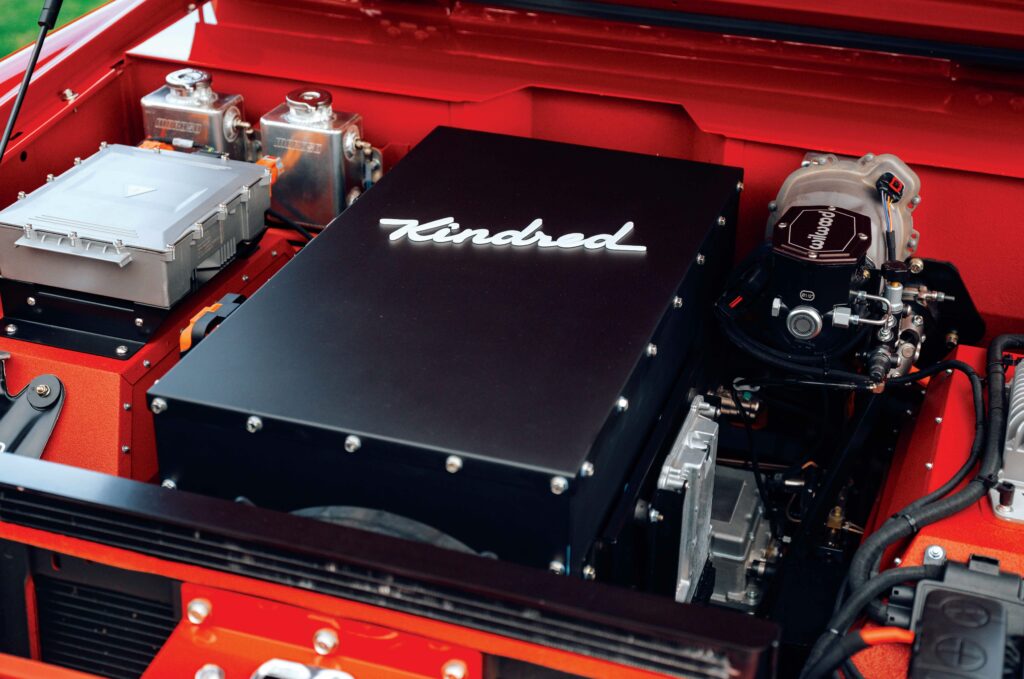

Power is provided by an 80 kWh battery, which comprises three separate Kore Power VDA modules, all wired together into one unit. The largest sits in the centre of the vehicle, between the two drive units; a smaller one replaces the original fuel tank, behind the rear axle; and the third is housed in the engine compartment, above the front drive unit.

The additional electrical plumbing and connections needed to piece together the three sections is not ideal, but the layout enables the battery and chassis to be a single fully integrated platform, retains a significant amount of functional interior space and spreads the weight around to create excellent balance while also lowering the centre of gravity.

“It was a real challenge to get that size of battery in the frame,” says Friesen. “Some folks who are doing EV Broncos are putting batteries in the rear cargo area, raising the rear floor, but we didn’t want to do that. It’s not ideal to do three separate battery sections, but it means we don’t have to compromise interior space.

“Also, when we’re building the car, all the batteries are on the frame, so we can build a chassis system that’s complete. It’s not a skateboard, but it’s like a skateboard, and you can just lower the body on top. You’re not trying to connect batteries between the two, which actually adds a lot of manufacturing ease.”

The battery pack employs Nickel Manganese Cobalt chemistry in a VDA 355 form factor, which was chosen to optimise energy density while ensuring effective thermal management. The modules are mounted directly onto chill plates, allowing for precise temperature control during both driving and charging conditions.

The cells support a peak discharge rate of 2.7 C and modular construction is used to further enhance safety, with each VDA module housing 12 isolated cells to limit propagation in the event of a failure. An air gap between modules, combined with a multi-pack layout, provides additional thermal isolation.

Given the vehicle’s off-road focus, the battery packs are shielded by rugged skid plates and designed to meet the IPX6 ingress protection standard. They are mounted using rubber isolation bushings, which decouple them from the chassis and prevent frame flex transmitting damaging forces to the enclosures during extreme manoeuvres.

The batteries are charged using the well-supported Combined Charging System, although the team plans to switch to the North American Charging System in the longer term. The Level 3 DC fast charging is battery-limited up to 80 kw but efficient battery thermal management enables higher charge rates in various conditions.

“Charging is battery-limited,” Friesen explains. “The battery we have just doesn’t have a real fast charge rate on it, but we have also been pretty conservative. We’ve created a charging system that can work dynamically. So, depending on the state of charge and temperatures, our system will allow the rate to change.”

The dynamic charging strategy is based on cell temperature and state of charge (SOC) and employs a Constant Current–Constant Voltage charging profile. This allows the system to maintain 60-80 kW during the bulk of charging, with a gradual taper in current above 80% SOC to protect battery health and prevent thermal runaway.

The vehicle control unit dynamically calculates safe charge and discharge thresholds based on SOC and thermal data. Safety during servicing is also a top priority and the design includes a prominently located MSD fuse in the engine bay, which, once removed, breaks the HV circuit and disables the external terminals, making the vehicle safe to work on.

Cool innovation

Kindred has developed a highly sophisticated in-house battery thermal management system for the EV Bronco, which constantly monitors and manages cell temperatures. When needed, it circulates water-ethylene glycol coolant through two separate cooling loops to separate sets of chill plates.

This is one of the most important and innovative aspects of the vehicle, and a significant amount of time was spent on its development. Friesen explains: “There are EV conversion kits out there for different cars, but one thing that they have never really included is a battery thermal management system that actually works.

“During testing, we found that a passive system that circulates water around the battery, just through a radiator, doesn’t really work. If it’s really hot outside, you can’t cool the water lower than that. So, we’ve integrated a refrigerant chiller system in the Bronco and we can also apply that to all of our models in the future.”

The system takes the traditional HV water heater, which was fitted for cabin climate control, and turns it into a double duty system that can also heat the battery, and Friesen adds: “This is now what many OEMs are doing for range control, but In the EV conversion world, it’s pretty advanced.”

One of the two circuits is dedicated to the motors and inverters, but the other is shared between the battery system and cabin HVAC. The motor/inverter loop continually circulates coolant through an air/water radiator, with an electric fan triggered when needed, and the cabin/battery system employs an HV A/C compressor and positive temperature coefficient heater.

This enables precise temperature regulation based on sensor data during both the drive and the charge cycles. Sensor feedback plays a critical role in the real-time thermal and system management, with sensors monitoring air temperature, water temperature, refrigerant pressure and coolant flow to ensure efficient operation across diverse driving conditions.

“The system allows us to ensure the battery remains within ideal temperature ranges, which is especially important during fast charging – to maintain both performance and longevity – and in extreme conditions,” explains Friesen. “Cold weather driving can have a particularly big impact on range, and this gives us better efficiency and consistency of range.”

Kindred has developed its own software to manage the system, which takes the battery temperature, ambient temperature and even predicts how the car is being driven, to try to stay ahead of the battery’s temperature fluctuations and maintain it at the optimum operating temperature.

The team even took it down the road to Death Valley to test it, and Friesen explains: “That’s where all the automakers go because it gets up to 120 degrees Fahrenheit there. We went there to punish the car as much as we could, making sure we could keep the motor inverter system, the batteries and the cabin cool, all at the same time.”

The entire system is designed to meet rigorous functional safety standards, including HV interlock and isolation monitoring, comprehensive fault detection across the powertrain and BMS, and strict validation of Controller Area Network (CAN) messaging and sensor data. Before any HV switching or drive engagement, multiple safety checks are performed.

In fact, the entire old fuse and relay wiring system has been replaced by a power distribution module (PDM) and new electrical harnesses to manage and distribute all the electrical power across the different components, with the software programmed to carefully manage the entire process and allow greater control, reliability and flexibility.

A bespoke Kindred 12 V harness, which funnels 12 V power and communications throughout the vehicle, was originally developed for the petrol-engine Bronco and optimised for the EV version. The HV wiring harness, which is specifically for the EV system, does a similar job, efficiently routing the power for charging and the drivetrain.

The old approach to wiring harnesses involved having a wire for each function, whereas the more modern system uses networks to communicate with different components. This allows messages to be sent wirelessly from one device to another, without huge amounts of cable, and has enabled the team to create the best possible layout and components.

“There are so many functions added onto these cars over the originals that there’s just no way to keep the original system,” explains Friesen. “There’s a lot of information running around on the CAN bus and although it makes it much more complicated, it also makes for a really modular platform with an expandable feature set.”

Modern refinement in traditional form

The EV Bronco interior is filled with retro details, the most notable being its beautiful range indicator. Unlike modern vehicles, which typically have displays of bright digital numbers and waves of green, orange and red that move to indicate economical driving, this vehicle’s range read-out looks just like a simple analogue fuel gauge.

To place such an important piece of information in the hands of a very basic looking readout is indicative of Kindred’s approach to this restoration – because behind the simplicity and original detail is an extremely sophisticated system that ensures unwavering accuracy of the needle.

One of the big challenges in the development of the EV Bronco was the need to integrate all the functions expected in a modern luxury vehicle – air conditioning, satnav and a touchscreen system – into a vehicle that originally came with wind-down windows for cooling, a map book for navigation and a rudimentary dial-tune radio for entertainment.

In doing this, the team was determined not to lose the original feel of the Bronco and Friesen smiles: “Putting a motor and a battery in is actually the relatively straightforward part. If you want a really refined car, it’s the interface points the driver experiences that really need to work right and be reliable, so that’s where a lot of our focus went.

“The Bronco is a unique driving experience, the way you sit in it, the way it feels inside, and we have tried to maintain that throughout the vehicle. We didn’t want something that looked super modern. It had to keep the same aesthetics – and the range gauge is a great example of how we’ve really tried to follow the original design.

“It’s really hard to get accuracy on range – even the OEMs have challenges having accurate countdowns – so the gauge is a great solution. We also use the original shifter as a state selector. Things like that, we just tried to have a nice tactile and mechanical feel because that’s what people want in a modern classic car.

“With the 12 V electrical system, the electrical PDMs are totally programmable. So, we can hook an old light switch up to it, run it through the system and make it do whatever we want – so we can keep some of those neat original features, but instead of physical controls, they are all connected through a modern CAN.”

The car has four comfortable leather bucket seats, cut and sewn in-house, with the rear bucket seats providing extra comfort compared with the original rudimentary bench seat. Even shoulder-style seat belts were not part of the original vehicle, so obviously these have been added into the modern construction.

Owing to the updated wiring system, there was no longer need for a cable to drive the speedometer. Therefore, the team worked with industry leaders in gauge clusters to develop a bespoke cluster that has a modern networked connection, yet retains the classic aesthetics of a true Bronco gauge.

Similarly, the centre console has a run of analogue-style toggle switches to control all the power windows, power door locks and even heated seats, while an aluminium centre console between the front seats contains two cup holders and a wireless phone charger – two ideas that were not widely adopted when the original vehicle was created!

The flush-mount car charger access door is designed to be reminiscent of the 1977 fuel filler door, while the car also keeps the quirky traditional Bronco feature that allows owners to take the doors off and drive open sided – although Friesen is not sure whether any customers have actually done that yet.

Modern additions are seamlessly blended with classic style, notably in the electrically retractable step, which makes climbing up into the high-sitting vehicle a far less ungainly process. The interior layout also provides good road vision, while the traditional open top comes with a fabric shade to allow open-air driving, protected from the sun.

The one interior element that had to give, however, was the in-car entertainment system. Now, in place of that beautiful old radio in the boxy centre console, surrounded by chrome turn switches, is a high-resolution touchscreen. “That was a tough one,” concedes Friesen. “If you want Apple CarPlay and modern convenience, it doesn’t particularly look vintage.”

Mechanically, the car has been stripped of its original 1960s-designed link steering system and braking system, as neither was adequate for today’s exacting standards. In place, it gets rack and pinion steering with electric hydraulic assist, four-wheel disc brakes and a regenerative braking system that puts power back into the battery.

Independent front suspension and a multi-link coil-spring rear suspension transforms the way the car drives on the road thanks to the help of a significant amount of multi-dynamic CAD modelling, which helped optimise the new suspension to the vehicle’s weight distribution.

“That was an engineering challenge, trying to fit modern components on a chassis that was never designed for them,” continues Friesen. “The new steering system offers a more refined ride and driving experience, and there is regen braking on all four wheels, although it’s calibrated to mimic a conventional automatic transmission.

“Regenerative charge currents are kept well below the battery’s peak input capabilities and it’s not like a one pedal drive, where the car slows down when you take your foot off the accelerator. We wanted it to be at the level where if you step out of an ordinary car and drive this one, you can feel some braking but it still has a similar feel.”

Tuned for performance

The re-imagined petrol-powered Bronco is heavier than the original by between 350 and 450 kg, with the electric version adding another 120 kg on top of that figure. Much of that is down to additional equipment, including the air conditioning chiller unit for interior comfort, the modern braking and steering systems and the integrated rollbar.

Despite this, the performance is a step-change beyond the original and Friesen explains: “Back in the day, the Bronco didn’t handle good, didn’t stop good and even the V8 version was pretty underpowered! They were really a cheap mid-sixties car, but they’re so special and uniquely designed, they’re kind of the first SUV, so people love them.

“It was pretty easy to improve on the performance of the original, but the question was more how far did we go with it because with the EV drivetrains that are available now, the sky’s the limit for power. We wanted something the average driver can handle, so the tuning approach we’ve taken is to improve horsepower and torque, but not gratuitously.

“It’s a short wheelbase, four-wheel-drive car, so if we ran the drive units at full power, it would overwhelm the chassis. It would just create too much power and the handling then becomes a little sketchy. So, the first thing we did was just wind back the power and set the front and rear bias so that it’s fast, but it’s also safe and predictable.

“There’s nothing actively changing the power bias front to rear, each drive unit has a limited-slip differential so they keep good power from left to right axles and we just tuned it to be driveable. The set-up of the battery also means that we can’t run all the power all the time and keep the battery cool; you simply wouldn’t want to, so we did some tuning there too.”

In the new electric world, everything has to be efficient to maximise range and battery usage, and that presented a significant challenge when it came to the Bronco. Its high-drag square-front body shape is not designed to cut through the air, and its original rugged but loss-filled mechanical set-up added plenty of rolling resistance.

Friesen concedes: “It was a really tough starting format for efficiency because I don’t think any thought was given to aerodynamics when they designed it! The fact that it’s heavy, tall and four-wheel-drive doesn’t help either – but we wanted to maintain that aesthetic, so there are lots of things that are all fighting for range and it’s all a careful balance.”

The company targeted a 200 mile range for the EV version, based on the belief that this distance is plenty for the daily use cases most owners would require. However, with the aforementioned challenges, it proved a tough target to achieve owing to the diminishing returns of bigger batteries when it comes to weight and handling.

“We have gone 200 miles in it, but as with any EV, it really is dependent on how you drive it,” says Friesen. “I think on any EV conversion, it is much more pronounced than, say, on a Tesla. If you’re driving really aggressively, that range number fluctuates a lot because of the baked-in inefficiencies like the aerodynamics and drag, which get bad when you go faster.”

The team explored all aspects of the vehicle performance to seek efficiency improvements without changing the look and one of the most successful changes was in terms of the tyres. The team tested many different makes and types, and managed to find a solution that maintains the rugged look but extends the range significantly.

The car comes with one fixed drive mode that aims to suit all comers, but Friesen says his team is currently evaluating options to offer different settings for the regenerative braking, investigating the addition of traction control and actively developing some potential driving modes, all of which are currently running as r&d projects for future versions.

Although over-the-air software updates are not currently supported, easy servicing is ensured through XCP diagnostic protocol compatibility. This interface allows technicians to access real-time data across thermal, powertrain, BMS, HV charging and auxiliary systems using widely available third-party tools.

Right now, the aim is to keep things simple and Friesen adds: “These cars are just meant to be driven and for a car shaped like it is, it handles really well. Switchable modes can add a lot of complexity, so we tried to make it simple, so that if you hop out of a modern car and into this it doesn’t drive much differently – and I think we’ve achieved that.

“We have a bunch of people here who are all real serious about their cars and we all fight over what it should drive like. Is it torque steering too much? Is it spinning the front wheels? Is it accelerating smoothly? Over time, we’ve got it tuned to a point where it’s very nice to drive and the handling is so much better than the old trucks.”

Friesen says many people feel the EV version actually drives better on road than the petrol version, mainly because of its independent front suspension and rack and pinion steering. In contrast, the petrol car has a more traditional solid axle, which, while exceptional off-road, makes things a little rougher compared with modern cars on the road.

The EV, however, is still highly capable off-road, with full-length skid plates to protect the underside from rocks and some careful throttle mapping to keep the immense torque of the twin electric engines in balance. Friesen adds: “EVs are great for off-roading because there’s just so much torque and so much control of the throttle.

“When we put it through its paces off-road, we found there really wasn’t much of a need to control the torque front and back. Maybe in really extreme off-road conditions it might need some management, but for the kind of stuff that we pushed it through, which is probably beyond what the people who buy these cars might do, it works great.

“In fact, we’ve taken the gas cars and the EVs off-road together and people really like the EV because it is so controllable, it’s quiet and it manages the obstacles really well. The gas car is capable of more hardcore off-road, because we’ve designed it to have all the 4WD trickery with big axles, lockers and all the traditional stuff, but the EV more than holds its own.”

Future evolutions

Kindred has now fully completed more than 50 of its petrol-powered Broncos and produced six EV Broncos, all of which are still currently at the company’s headquarters: one being used as an engineering development car, one as a prototype marketing car and four that have been built with production intent for potential customers.

The current production line, which enabled the team of technicians to build around four vehicles per month at the start of 2025, is projected to rapidly scale up so that as many EV Broncos can be produced as demand and capacity allow.

The carefully built EV team is filled with engineers who are following their personal passion. It includes a former Tesla employee working on thermal management systems; a controls expert working on the air conditioning system; a restomod company founder; and six engineers who build their own EVs at home in their spare time.

This deep knowledge has helped Kindred develop reliable sources for all the EV components and efficiently integrate them into a fully functional EV powertrain. Its philosophy is to never simply take the ‘easy option’ – an example of which is the decision to fit entirely new suspension, rather than simply retain the original, to achieve better performance.

The company’s impressive facility is an old submarine base on Mare Island, and its exciting pipeline of vehicles has attracted a number of staff from the nearby Tesla plant. This has enabled the company to extract some valuable insights from a much bigger OEM company, and apply those to building their custom classic cars.

“We’ve learned a lot of interesting things from that,” says Friesen. “We’ve understood just how important good fixtures and jigs are to make things totally repeatable, and also how important it is to manage the supply chain, bringing all the parts here and ensuring they are good quality by inspecting them all as they come in from vendors all over the world.

“In the EV world particularly, that has been a huge challenge because there’s this whole new cast of characters for EV suppliers that are not the typical automotive suppliers. Just getting those parts onto our site can be tough; some of them have very long lead times, and the importance of getting everything staged and ready to go is one of the biggest takeaways.”

Thanks to the evolving MES, the development process for the EV Bronco is improving month by month. Whenever a process is identified that is taking too much time or is suffering a quality issue, the team will go back and revisit it, improve it and programme a new, repeatable solution into the software.

That efficiency is something that will become increasingly important as new models are added to Kindred’s roster and there are plenty in the pipeline. The company says that every year it is now aiming to introduce three or four new models, expanding a portfolio of new machines all based on popular classic vintage cars.

The VW bus is well down the development schedule, with its second iteration learning from the first and the third version benefitting from the EV development on the Bronco. A ‘test mule’ has already been on the road accumulating miles to evaluate the new systems, which although not exactly matching those on the EV Bronco, do follow similar principles.

Although they are tight lipped about what is coming after the VW bus, they have hinted that a sports car is on that list of future models. The challenges will be largely the same for all these different upcoming vehicles, so the EV team will now continue to take their findings from prototypes and production designs and apply them to future models.

“The VW bus is really special because it has a really unique interior and it’s going to be a great car,” smiles Friesen. “We’ve done a lot of development on that one; we built three prototypes leading up to the version we’re building now, so I’m really happy with how it is developing and I’m excited about what’s coming next.

“We’re just at the tip of the iceberg of the whole automotive industry making a huge changeover to electric, and we’re at a point where we can now really start to make the most of this new EV technology and create classic cars that are environmentally friendly, and also deliver really quite dramatic performance gains.

“These cars all have really interesting design features that people love and we want to keep all that, but we want to eliminate the stuff that nobody likes, like the terrible braking, or the 40 bhp of power, or the breaking down all the time. If we can get rid of that, modernise the performance and still maintain the car’s character, we’ve done our job.”

Specifications

Performance

Horsepower: 402 bhp

Torque: 492 lb-ft

Technical

Vehicle origin: Ford Bronco 1966-1977

Motor: Twin Cascadia Motion IDM 190

Battery: 80 kWh in Kore Power

VDA modules

Differential: Front and Rear Wavetrac limited-slip diff

Charging: Level 3 DC Fast Charging

Brakes: Four-wheel power discs and regenerative braking

Suspension: Independent front, multi-link coil rear

Click here to read the latest issue of E-Mobility Engineering.

ONLINE PARTNERS