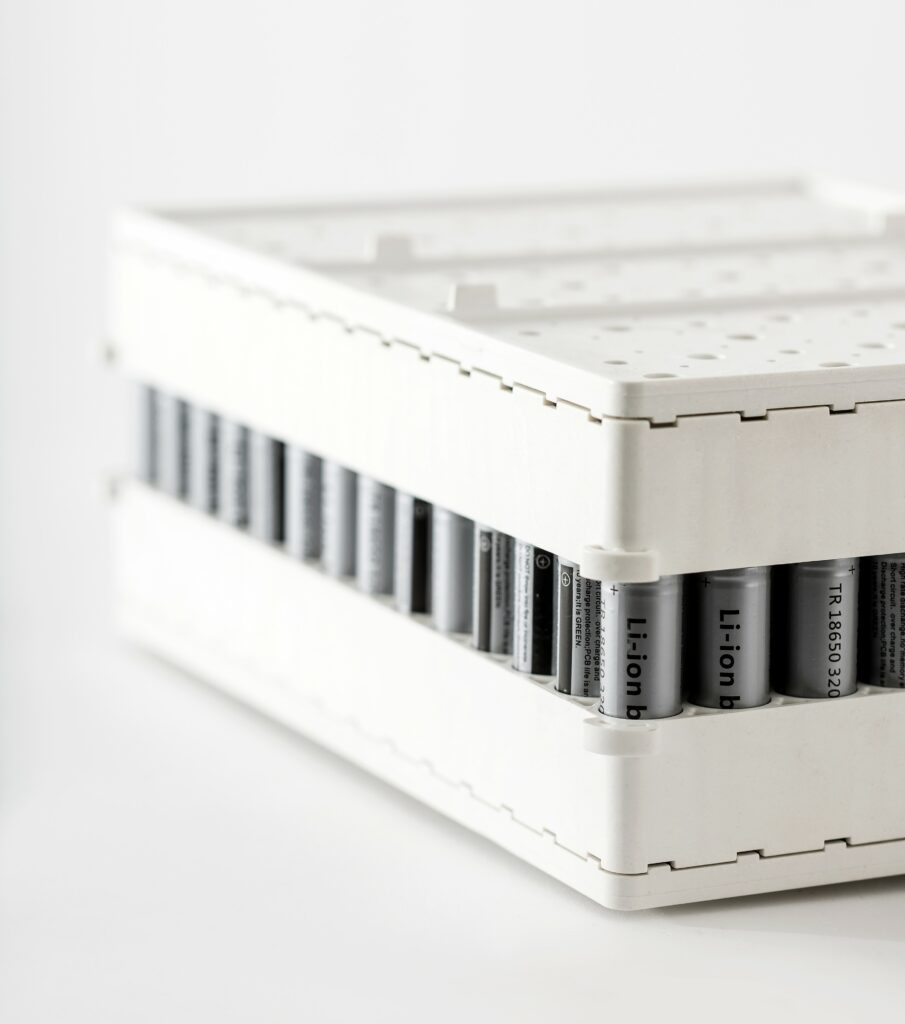

Pyrophobic Systems develops moldable intumescent thermoplastics for battery thermal runaway protection

(Image courtesy of Pyrophobic Systems)

Fire safety is no longer a secondary design consideration for e-mobility battery packs, but an integral component at every stage of product development. The growth in high-density energy lithium-ion battery packs has highlighted the need for thermal runaway propagation mitigation.

Designers need to create passive fire protection systems that isolate dangerous thermal events, confine them, and prevent them from igniting adjacent cells or spreading to the rest of the facility.

Traditional solutions have included coated metals, fire-resistant plastic enclosures, and layered composites such as fibreglass-laminated panels. However, the rapid changes in regulations and the surge in demand for more robust, space-saving, and cost-effective passive fire protection solutions have driven engineers to consider new materials and solutions.

Pyrophobic Systems has developed a patented engineered intumescent thermoplastic called LithiumPrevent specifically for lithium-ion battery fire protection and thermal runaway containment. This can be molded into busbar caps, cell holders, spacers, or entire pack lids, delivering a single material with fire resistance, heat absorption and the ability to contain and prevent thermal runaway.

The material expands when exposed to high temperatures or direct flame. This expansion of 2 to 3x forms an insulating layer that helps thermal runaway containment by creating a char layer that protects the substrate and contains the thermal events.

Intumescence occurs when certain additives within the polymer begin to degrade at a specific trigger temperature, decomposing into water vapor, and gas. These gases expand within the polymer, swelling into a foam-like char that acts as an insulating barrier. The expansion of the polymer also reduces the amount of oxygen available, slowing or extinguishing the fire.

Various formulations can be injection molded or extruded into complex geometries such as busbar caps, battery cell holders, or poke-through electrical firestop devices. They also go beyond UL 94 V-0 classification for self-extinguishing behaviour with time-temperature curves that are representative of real-world thermal runaway events.

Click here to read the latest issue of E-Mobility Engineering.

ONLINE PARTNERS