Marlen Valverde of H.B. Fuller explains advances in adhesives and coatings for EV batteries

(All images courtesy of H.B. Fuller)

Developing a special chemistry

Marlen Valverde, global technical manager ePower and energy storage at H.B. Fuller, speaks to Will Gray on the importance of adhesives, sealants and coatings in EV batteries

The development of battery technology is vital for EVs to break further into the mainstream. As the chemistry and architecture of the packs evolve, however, there are increasing demands for advances, quite literally, in the glue that bonds them together – and Marlen Valverde is one of the people at the forefront of that work.

“This industry is still in its infancy,” she explains. “We have created a lot of know-how around what makes a successful battery pack, but that’s still evolving, and while the materials that have been supplied until today have been successful, to varying degrees, there’s still a lot more fine-tuning that needs to happen.

“The core technology itself, the cell chemistry, is still changing, and that dictates everything else, including the design and geometry. That, in turn, changes the requirements of the adhesive and sealants. So, it is all about active learning and we’re not done yet; it’s still evolving and we’re still trying to react as fast as the battery industry requires.”

Valverde grew up amidst the stunning wildlife of Costa Rica, so it was inevitable that her career would be heavily focused on sustainability. However, when she first started out, the EV world was very much in its infancy. So, after earning a PhD in the US, she joined the Renewable Energy Group to work on organic chemistry synthesis for bio-fuels.

“I was always interested in learning how to use chemistry as a tool to find ways to do things more efficiently and more sustainably; to reduce environmental disruption and potentiate the use of resources we have at hand,” she recalls. “At the same time, I have always had a passion for cars because my dad instilled in me a love for engines and how they work.

“At that time, EVs weren’t a thing and bio-based materials were the future. That was perfect for me, as it involved using readily available materials to create better sustainability than the fossil fuels used in engines – but there was always a question mark over whether the growth of these vegetables should be dedicated to feeding humans or making fuel.”

Her work there was cut short, however, owing to the fragility of the US economy, with the company unable to support her young international graduate status. She returned to Costa Rica and began working as a senior r&d scientist for H.B. Fuller, where she was given the dual role of plant chemist and head of architectural and industrial coatings.

This wide-reaching remit involved developing materials for metal applications in the marine, architecture and automotive industries and – crucially – gave her an early insight into the regulatory requirements in the automotive industry and how chemical development plants need to operate to supply that market.

Into the world of adhesives

After almost two years, an internal transfer within H.B. Fuller took Valverde back to the US, where she began working on reactive adhesives for automotive interior trims. The new role brought her focus backonto sustainability, with one of her aims being the reduction of scrap and contamination in the manufacturing process.

She was also tasked with trying to increase the amount of bio-based material within the formulations as well as the recyclability at the end of life and how the components can be harvested and reused. These requirements continue to be a priority in her current role – but when it comes to adhesives, recycling efforts bring with them a very unique challenge.

“It’s an interesting balance,” she begins to explain. “We have to provide adhesives with the strength to survive 20 years inside that car without any problems – no delamination, no movement, no tearing, ripping or detaching – but then one day, when we want to recycle this car, it should pose zero problem for harvesting the component!

“That action looks different for every different application, every different customer, every different market. It is important to generate extremely deep knowledge of what we’re trying to do, so that when the material gets formulated, it fulfils the expectations through its life. That is something I have been doing for many years now!”

Over time, her role grew into covering other applications within a car – headlamps, exterior trims, under the hood applications. Eventually, she became the technical manager for automotive and transportation and travelled all around the world to better understand the automotive world from many different angles and in many different regions.

“These were highly regulated, highly controlled markets and you learn quickly that you cannot do a single change in any single formula without full clear communication,” she explains. “It has to be documented and you have to prove the change is not causing any issues to the performance of the material.”

Arriving in the EV space

It was in 2020 when her role radically changed following a leadership meeting focused on the growing EV market. Recognising the importance of adhesives and coatings in the battery space, the senior management team wanted to know if the company was aligned and had the knowledge to start formulating the materials needed in the market.

“We looked at each other and nobody knew what to answer,” she recalls. “So, I came out of that meeting and one of the vice presidents of the business chased me down and said: ‘Hey, do you want to be that person; to be the scout out there in the market?’ So, soon after that, I became business development manager for the entire electric battery space.

“The target was not just for EVs but for everything electric – handheld tools, energy storage systems, vacuum cleaners, lawnmowers, anything with a battery. They basically gave me a map of the United States and said: ‘Go for it! Go find this business.’ It was a daunting task, but at the same it was a privileged one.

“I focused on targeting the customers that I knew and had been working with, those I knew already were working on battery projects. I slowly started to get communication with them, build relationships with the key stakeholders in those companies and start learning about the application at the same time as my customers.

“We entered this space at a time where everybody else was also learning. So, I helped them learn, they helped me learn, and together we developed the definition of what is important for the performance of a material in this space, and the knowledge required to successfully formulate those materials.”

Valverde’s scope involved anything immediately outside of the cell, identifying applications where there was a need for an adhesive material and understanding how it could enable better battery functionality and optimisation. The focus quickly evolved into sealants, encapsulants and coatings as well, to meet the advancing requirements.

As the market grew, Valverde became so successful in harvesting all the information and learning what new materials would be needed to meet global demand that the company’s innovation portfolio became vast. It needed managing and she was the obvious choice to take the role, adding it to her ongoing work scouting the market for new opportunities.

Developing the next generation

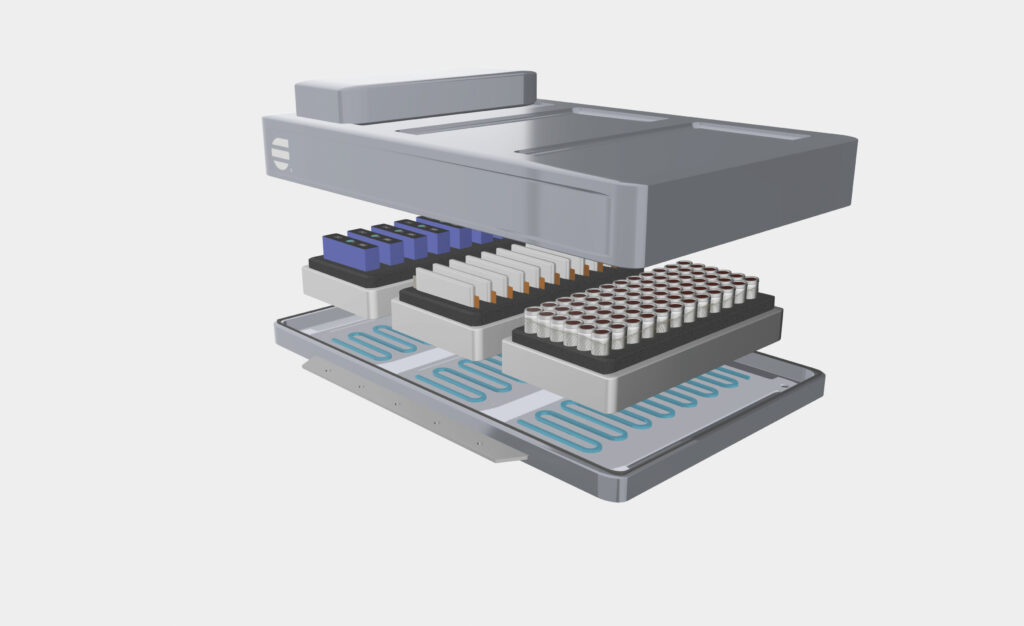

One of the biggest influences on the work of Valverde and her team has been changes to battery architecture design. In an endeavour to deliver ever-higher energy density, better battery efficiency and extended range, designers are having to pack increasing numbers of cells into the same space – and that has led to a revolution.

“There has been a change from ‘cell-to-module-to-pack’ architecture to just ‘cell-to-pack’ designs, skipping the whole module approach,” explains Valverde. “Losing the intermediate metal box protection of the module has had a tremendous effect on the requirements for the adhesives that now bond the cells to the pack.

“We now need to create materials that are far more structural and far easier to apply and with the added demand for faster production, a lot of the steps have to happen very quickly. Thousands of units need to be produced per day so there’s now very little time for the adhesive to build up strength, and that has definitely influenced our latest innovations.”

In the EV industry, time is money and Valverde’s team is working hard to introduce new materials that can lower costs by reducing the application complexity; reducing the application time; reducing the length of curing needed before the process can move to the next step; or reducing the overall amount of material that is needed.

“We want the electrification of transportation to take place and if consumers cannot afford to buy an EV, it is either never going to happen or it is going to happen very slowly,” explains Valverde. “That’s no good for anybody, but making materials cheaper is not always possible, so we try also to reduce the cost of the overall process by making things more efficient.

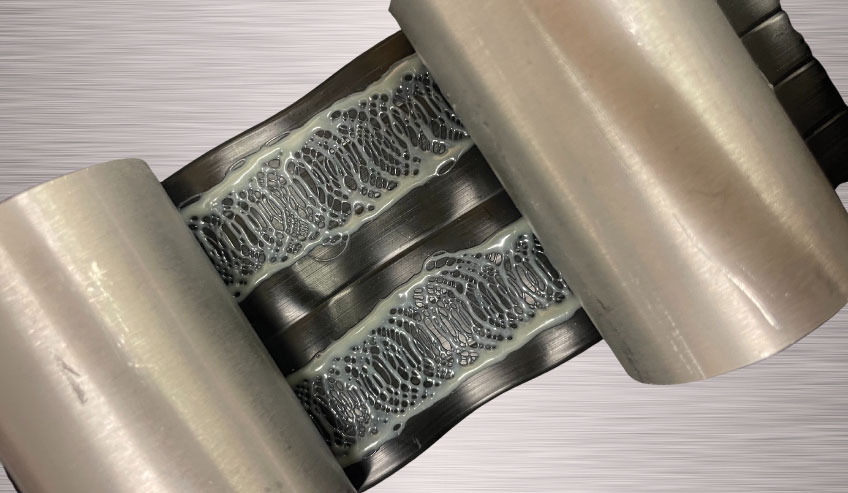

“One good example is our EV Bond 775 hot melt reactive adhesive, which is formulated to be applied in a molten state. You melt it, apply it, and as it cools down and gets compressed between two surfaces, the molecules of the polymer have been deliberately formulated to arrange themselves in a way that immediately starts generating strength.

“The ultimate performance still requires the material to fully cure, but for the manufacturing steps, we can design materials that generate enough strength to allow the next process to occur without having to wait for the full curing time. That reduction in process time can achieve big savings for the customers.

“We are also working on reducing the number of adhesives required across the whole battery manufacturing process. To do that, we are developing the robustness of materials so they can bond to multiple substrates and under multiple geometries, and that is another one of our main focuses at the moment.

“We cannot claim we invented all these new approaches; they are often just chemistry tricks you learn at school and are already in use for other applications, but we connect the dots and make them work at a commercial scale for the EV industry. That’s achieved through lots and lots of formulations and r&d by an extremely talented team of experts.”

Into the future

Global electrification is not solely consigned to EVs, so neither is the work of Valverde’s team. The company is supporting companies that are developing space rockets, satellites, submarines and weather buoys, among many other applications, and the criteria for the bonding performance and surface materials involved are similar for all.

“There are slight differences, but for the most part I would say 90% of the requirements are the same,” says Valverde. “Just that last 10% may change from application to application – for example, if the battery is going into a military application or it’s being submerged, there are additional requirements such as ballistic strength and corrosion resistance.”

Solid‑state batteries are soon to enter limited commercialisation, driven by breakthroughs in ceramic and sulphide electrolytes. These have the potential to deliver two- or three-times higher energy density, dramatically faster charging and enhanced safety owing to the use of non‑flammable solid materials.

Meanwhile, second-wave chemistries such as sodium‑ion (Na‑ion) and silicon‑anode enhanced lithium‑ion are also gaining traction, with highly packed cells that promise greater power density, faster charging, low temperature capabilities, higher cycles and lower cost, with some designs slated for production by the end of the year.

These new technologies and chemistries, added to improvements in battery management systems with AI‑optimised charging, advanced thermal control and more robust recycling frameworks, are driving a holistic transformation in EV battery systems – and this is all leading to advancements of new adhesive, sealant and coating technologies.

Valverde explains: “Safety is a particularly important area. There is an intrinsic issue with the chemistry of battery cells, in that if there’s an error in manufacturing or in the environment of the cell and how it operates, it could reach a situation where it gets overheated – and batteries can do so in a very dramatic and catastrophic way.

“As the energy density of batteries increases, the need for zero problems and zero errors increases, so our materials need to provide behaviours and performance that help prevent catastrophic outcomes. That includes flame retardancy, fire-fighting activity, smoke absorption, efficient cooling and many other properties.

“If you’re bonding a big heavy cell to a cold plate – which is there to draw heat away from the cell so it never gets too hot to get to the danger zone – we need an adhesive that will create the bond but that does not block that heat transfer efficiency. We need to formulate a material that enables effective heat transfer and we do that in a molecular way.

“We have also developed a new dielectric coating that reduces electrical losses to improve efficiency. There are lots of metal structures around the cells and if they touch there will be current leakage, draining the energy of that cell at a moment when it’s not necessary. This coating renders those metal surfaces non-electrically conductive.”

As well as advancing the capability of the materials, Valverde is also using past experience to make them more sustainable. She says there is a big pull in the market for adhesives and sealants that are more environmentally friendly and offer long-term recyclability – but, just as she found with the interior trim adhesives, it is not easy to achieve.

“There’s a term, ‘on-demand’ bonding, which is all to do with controlling how and when materials join together,” she says. “These are hard technical hurdles, holding components together for 20 years then, one day, clicking your fingers and everything falls apart! It’s one of the most complicated things to formulate – but we’re happy to take on the challenge.”

When asked to identify the biggest drivers in modern battery development, Valverde picks out two key areas: the continued use of lithium as the main ion for electricity generation, but at the solid-state level; and a longer-term switch to more abundantly available sodium as the chemical ingredient.

“My day-to-day work is focused on formulating for tomorrow and two years from now, not for the longer term, but if I answer as a consumer, I would love to see both those technologies become mainstream,” she concludes. “That would make everything safer and cheaper and open the door for the mass adoption of the electrification of everything.

“It’s a slow, step-by-step process and there are many issues that have to be considered, so I will give the scientists in charge of that enough time for them to figure it out! My main concerns today are enabling the reduction of manufacturing costs and improvements in safety – and we are constantly finding more and more ways of achieving that.”

Click here to read the latest issue of E-Mobility Engineering.

ONLINE PARTNERS