24M Technologies’ Impervio separator targets EV battery safety with dendrite-deflecting technology

While EV batteries are statistically less prone to fires than their combustion-engine counterparts, the rare incidents that do occur can be catastrophic. Over the last year or so, 24M Technologies has developed an innovative response to this challenge: the Impervio separator, a new battery component designed to prevent internal short circuits, monitor cell health, and isolate faults at the source, writes Peter Donaldson.

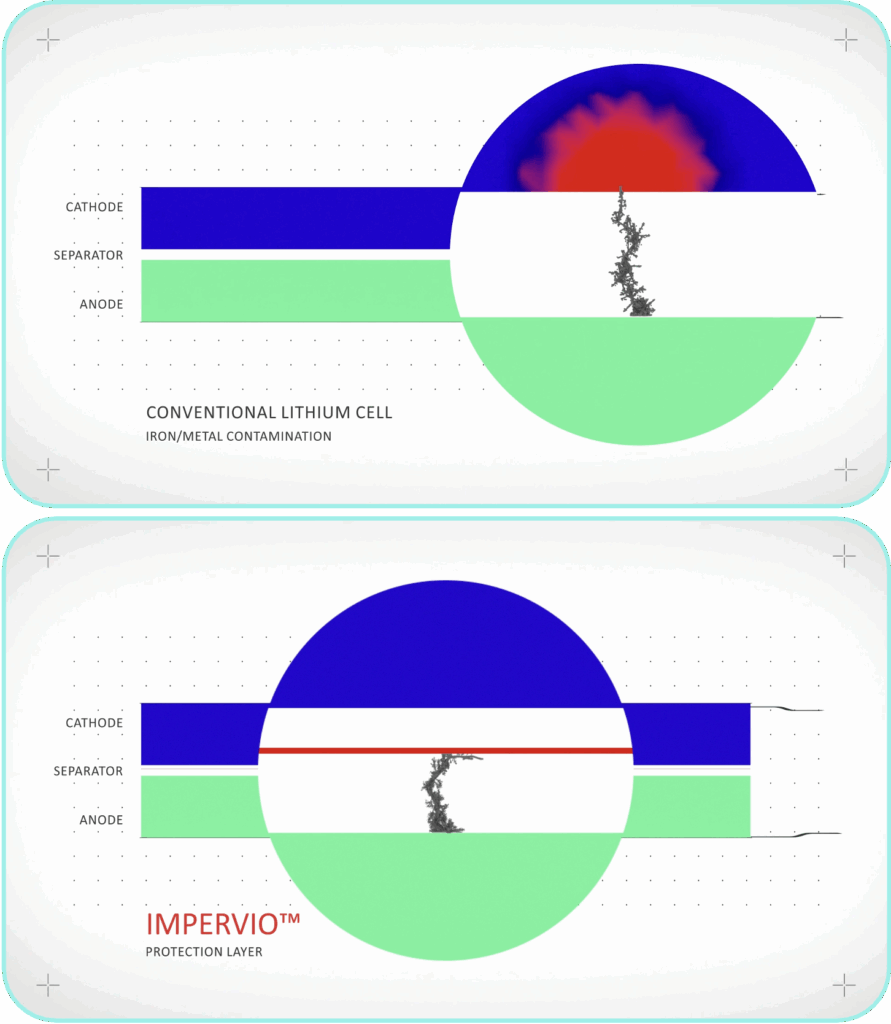

At the core of lithium-ion battery safety concerns lies the phenomenon of dendrite growth—tiny, conductive filaments that form within the cell over time. These structures can penetrate the separator between the anode and cathode, causing internal short circuits and potentially leading to thermal runaway.

“Dendrites can be caused by lithium itself or by production contaminants such as copper and stainless steel,” explains 24M’s President of European Operations Ulrik Grape. “Their growth is especially accelerated under stressing conditions—fast charging or low-temperature charging, for instance.”

The standard approach across the industry has been to reinforce containment and suppression mechanisms at the module or pack level to reduce the likelihood of fire propagation. Impervio, however, addresses the problem at its origins within the cell.

Dendrite deflector

Impervio is designed to tackle safety at the cell level through three key functionalities. First, it introduces a proprietary treatment to the separator, acting not just as a physical barrier but as a kind of deflector. Grape explains that the treatment makes the separator into something more than a tough membrane, as it actively suppresses dendrite growth by redirecting them away from the separator, preventing internal shorts even under extreme contamination conditions.

Second, Impervio takes monitoring beyond standard voltage and temperature sensing, incorporating diagnostics that can detect early signs of cell failure. While specific metrics remain proprietary, Grape emphasised that the system monitors cells “on a very detailed level,” far exceeding conventional battery management parameters.

Third, should an anomaly develop, Impervio’s monitoring system can interface with the BMS to isolate and permanently disable the compromised cell without affecting the rest of the pack. This enables “surgical” repairs, potentially eliminating the need for replacement of the entire battery or a recall of a complete vehicle model.

Ease of integration is another of Impervio’s advantages, Grape notes. The separator is a drop-in replacement designed to be compatible with standard production processes and to work in pouch, prismatic, and cylindrical cell formats.

Furthermore, it is chemistry-agnostic in that it has been shown to work well with high-energy-density NMC materials and more stable but lower-energy-density LFP chemistries, says Grape, who has been working with lithium-based chemistries since the 1990s. “I’m an old battery guy, and I know that any of these chemistries can go into a thermal event. This is about reinforcing safety regardless of the cell type.”

Wider application

The technology is also compatible with emerging solid-state batteries, where dendrite formation remains a challenge despite the improved safety profile of solid electrolytes, he emphasises.

While the initial application is clearly focused on automotive electrification, Grape was quick to point out the broader relevance of the technology. Electric motorcycles, stationary energy storage, and portable electronics—including the increasingly scrutinised power banks on commercial airlines.

Grape adds that the technology could play a pivotal role in aerospace electrification, where low weight and high energy density must be combined with safety. Lithium-metal batteries, highly promising for eVTOL and electric aircraft, are prone to dendrite formation. Impervio’s suppression effect could be key to unlocking commercial viability for these applications, he argues.

Rather than entering mass manufacturing directly, 24M follows a technology licensing model, partnering with OEMs and cell manufacturers to implement its solutions at scale. That said, Grape noted the company is exploring limited in-house production for some newer innovations.

Impervio is currently undergoing testing and evaluation with several OEMs, predominantly in Europe and the U.S. Given the automotive industry’s adoption cycles, a realistic timeframe for commercial deployment is between 2027 and 2029, depending on the aggressiveness of individual manufacturers.

Click here to read the latest issue of E-Mobility Engineering.

ONLINE PARTNERS