HV SiC MOSFET switch ships for EVs

Power Integrations (PI) has launched its first high-voltage switch chips for automotive battery packs that use a SiC MOSFET (writes Nick Flaherty).

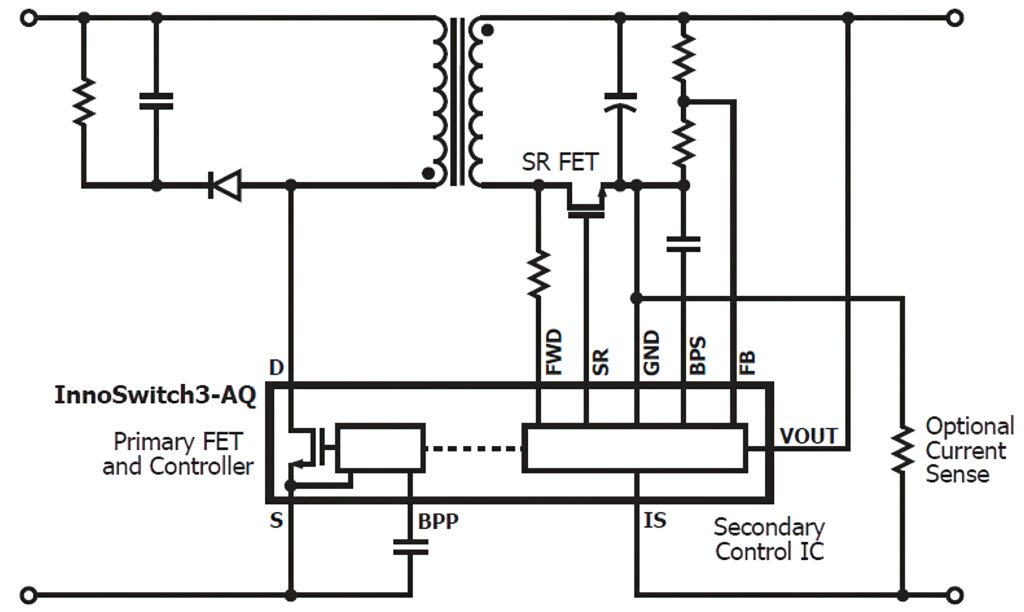

The package for the InnoSwitch3-AQ integrates a 1700 V SiC MOSFET for 800 and 1000 V battery packs where a 1200 V device would not be able to handle the peak voltage that can come from regenerative braking.

The switch allows the power of the pack to be used to power other parts of the system, such as driver chips, rather than relying on a separate 12 or 48 V power distribution network. Previous devices have used silicon or gallium nitride MOSFETs that could not reach the 1700 V requirement and needed additional MOSFETs in an 800 V design.

The device includes PI’s FluxLink magnetic isolation in the 24-pin package This provides isolation between the high side of the battery pack and the low side, with reinforced isolation up to 5000 V for secondary-side control. FluxLink also includes feedback across the isolation for direct sensing of the output voltage, providing benefits such as accurate regulation and extremely fast transient response.

The package also integrates a synchronous rectification and a quasi-resonant continuous conduction mode flyback controller. This has an efficiency of more than 90% and consumes less than 15 mW at no load, which helps to reduce self-discharge in BMSs.

However, that means the chip has to include safety features, for isolation and to safely power down devices if the pack fails.

As a result, the chip includes 30 V start-up circuitry, so there is no need for additional high-voltage components such as a linear regulator. This this can cut the number of components required for a power supply by as much as half, saving significant circuit board space, enhancing system reliability and reducing the challenges of sourcing components.

“The inverter has a large internal capacitance, and there’s a requirement for starting, stopping or in a crash that means the inverter has to discharge to less than 60 V in less than 2 seconds, even if the 12 V system fails,” said Peter Vaughan, director of automotive business development at Power Integrations. “The 30 V operation is to guarantee that the control electronics stays alive to discharge the capacitance, starting at 40-45 V in the specification.”

There are two versions of the chip that support DC-DC converters with outputs of 50 and 70 W.

Click here to find our more about Power Integrations and the InnoSwitch3-AQ

ONLINE PARTNERS