Henkel unveils new thermal potting solutions to boost electric vehicle power electronics reliability

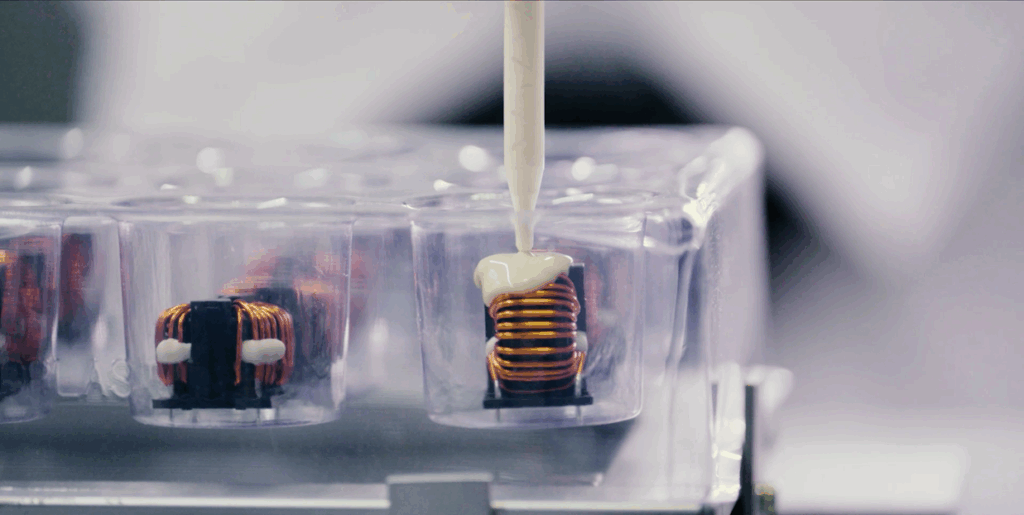

(Image courtesy of Henkel)

Henkel has announced two new additions to its thermal potting portfolio for electric vehicle powertrain systems, responding to the increasing demand for integrated x-in-1 architectures that combine inverter, on-board charger, e-motor, and DC-DC converter functions. As OEMs pursue compact, more efficient units and higher operating power densities, the challenge of managing heat and maintaining reliability intensifies.

Henkel’s latest silicone potting compounds, Loctite SI 5643 and Loctite SI 5637, are engineered to address these evolving requirements. Each material is a dual-component, fast-curing formulation with low viscosity that flows easily into narrow gaps and hard-to-reach spaces, enabling automated manufacturing and complete encapsulation of sensitive components. The compounds are pourable and self-leveling, which ensures uniform thermal contact and consistent physical protection against shock and vibration. Both maintain very low Shore hardness and a high degree of flexibility after curing, essential for minimizing stress during repeated thermal cycles in high-performance applications.

These advancements are the result of collaboration and feedback across Henkel’s teams and automotive partners, supported by the company’s global Battery Engineering Centers and network of specialist dispensing equipment suppliers. Loctite SI 5643 and Loctite SI 5637 offer different options for thermal conductivity, allowing designers to optimize for specific power conversion and battery integration scenarios. The company highlights their function in real-world EV integration, where next-generation thermal management materials are critical to delivering on system longevity and efficiency targets.

Henkel’s focus remains on accelerating the roll-out of new materials that meet the technical and operational priorities of global OEMs, battery manufacturers, and Tier 1 suppliers. The speed at which these products have moved from development to production underscores Henkel’s commitment to supporting zero-emission mobility and driving progress in e-mobility power electronics and battery design.

Click here to read the latest issue of E-Mobility Engineering.

ONLINE PARTNERS