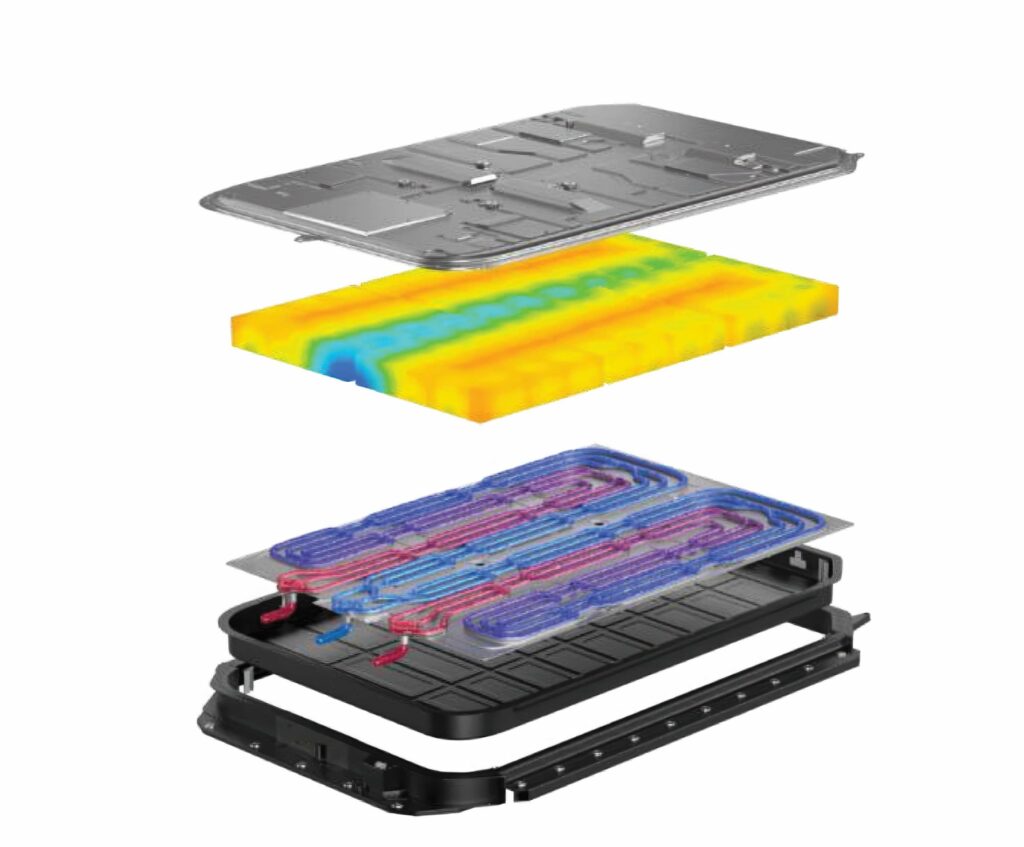

Digital twin for material optimisation

(Image courtesy of Henkel)

Henkel is launching digital twin modelling and simulation capabilities combined with real-world validation of structural materials used in e-mobility designs, writes Nick Flaherty.

Henkel is combining its expertise in material application with in-house testing and validation to close the loop between digital and real-world design and testing.

“Henkel’s simulation can optimise electric vehicle (EV) battery designs with greater speed, accuracy and efficiency,” says Dr. Stefan Kreiling, global head of innovation for automotive components at Henkel. “By integrating material simulation with real-world validation, we help accelerate innovation cycles, reduce development costs and bring safer, high-performance battery systems to market faster.”

The digital twin technology provides a closed-loop battery and materials development process using models of the battery systems and the adhesives, thermal interface materials and battery safety coatings. This allows OEMs and battery manufacturers to optimise designs at the earliest development stages, by simulating and testing the battery systems virtually before physical prototyping.

Henkel offers four key types of battery simulation for structural integrity, thermal management, fire safety and material application.

Structural simulation evaluates battery pack durability and crash resistance, optimising designs for weight reduction, robustness and performance under mechanical loads such as impact, crushing and vibration.

A thermal management simulation models the heat dissipation and cooling efficiency to analyse the battery performance, lifespan and fast-charging safety in extreme operating conditions.

Thermal event simulation predicts heat propagation pathways during a thermal runaway event to enhance battery safety measures and material utilisation, thereby reducing risks for passengers and critical components.

The material application simulation models the application of adhesives and sealants used in EV battery production. This reduces risks such as void formation, excessive squeeze-out and component stress.

This end-to-end digital twin modelling capability complements Henkel’s Battery Test Centre in Düsseldorf, Germany, which hosts the material and battery testing that provides the underlying data for the digital twin models.

Click here to read the latest issue of E-Mobility Engineering.

ONLINE PARTNERS