Henkel opens battery engineering and testing centre in Germany

(Images courtesy of Henkel)

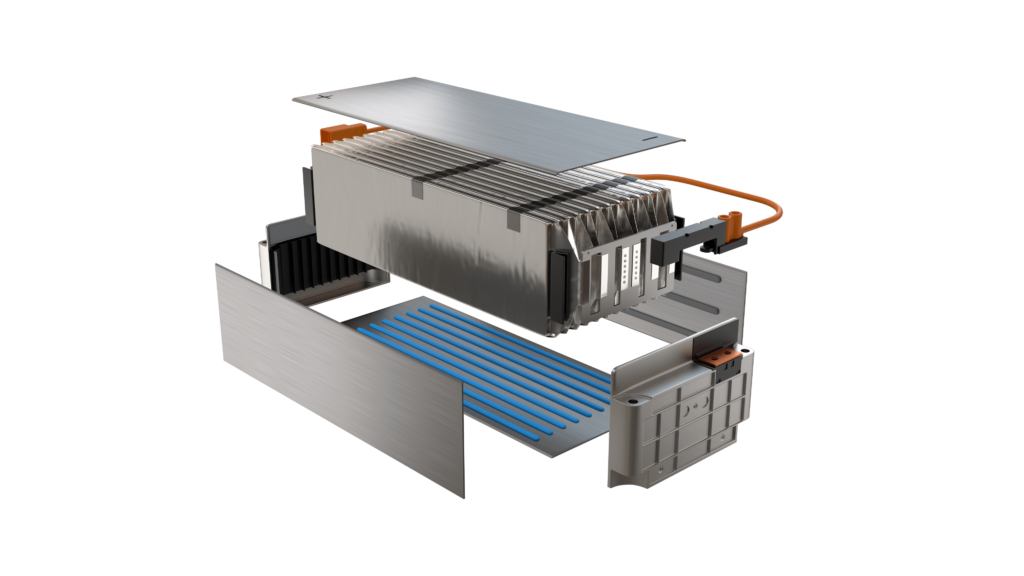

Primarily known as a producer of chemical solutions across several different industries, German multinational group Henkel has launched the Battery Engineering Center (BEC) within its Inspiration Center Dusseldorf, aimed at providing strategic partnerships with battery developers (and others in the e-mobility space).

Dr Olaf Lammerschop, global technology lead for e-mobility at Henkel, explains how the BEC came about: “E-mobility is a fast-changing industry. New battery designs appear on a monthly basis, which, in turn, has motivated us to strategically respond by developing new solutions for thermal management, such as thermal interface materials, and for battery safety, such as functional coatings, and also for structural integrity.

“That has led to Henkel having a large and growing portfolio of battery adhesives, sealants, thermal management products and other solutions, and all those have a major influence on the functionality of batteries. So, we became concerned about making sure the correct solution is chosen for the physical and performance specs of any given battery, and that the solution can be applied in the right way for serial production.”

After some internal discussion, it was agreed that planning and establishing what is now the BEC was the best way of not only ensuring the appropriate selection, use and integration of Henkel products into customers’ battery modules and packs, but also validating that this had been achieved, through exhaustive testing.

The customer’s journey

The first BEC is now operational, having been built with automotive OEMs and Tier 1 suppliers in mind – as well as battery manufacturers – who have a battery product for which the design is not yet fixed or complete, and wish to research how Henkel’s solutions may optimise their idea.

Such customers, when taking their battery concept or prototype through the BEC, will find their journey divided into three broad stages: first, the simulation and modelling phase; second, the assembly or application; and last, the testing and validation stage.

“We can help them find their optimal battery module or pack design through our range of intermediary components, and our large stores of data for modelling which components could be ideal for hitting their product targets, before taking it through to product development, application and testing,” Dr Lammerschop says.

“And that includes demonstrating and determining what kind of chemical application equipment, processes and lead times will be involved, as we provide extensive support for our customers in setting up the mass production process.”

Modelling and simulation

Initially, Henkel’s engineers will examine the design of a customer’s battery pack, and gauge its mechanical and thermal properties against its ideal or targeted performance specifications. They can then look across their products, such as structural or thermally conductive adhesives, to fulfil the pack’s stiffness or thermal requirements respectively.

“As cell-to-pack or even cell-to-car battery designs become more prevalent, choosing the right adhesives in this way is going to become more and more critical, because factors like torsional stiffness or even crash resistance at the adhesive level will filter through to how those parameters manifest at the level of the finished car, and similarly affect other holistic properties,” Dr Lammerschop notes.

“And part of simulation is not just virtually designing and testing different chemical materials of ours in and around the pack, but also formulating entirely new chemical products that we know we can create to fit the requirements unique to someone’s battery design.

“Based on our large material database of real and virtual materials, we will choose something that is an optimal fit and have our product development team create a material card of that non-existent but physically possible material, and then create the hypothetical material.”

A material card is essentially a digital list of a given material’s performance parameters and features, which characterises that material in a way that simulation software can understand and use for modelling, be it in static modes such as reproductions of vehicle mechanics or in dynamic modes such as crash simulations (including whether an adhesive successfully keeps the cells in place during a severe impact).

Whether the new product is an adhesive, a coating, a potting material, sealant or something else, it is likely to be created in one of Henkel’s Innovation Hubs (one is in Dusseldorf, one is in North America and the other is in Asia-Pacific). After a sample has been produced, it can be taken into the BEC, installed in an applicator, and robotically applied under serial production conditions into the customer’s prototype to see if it extrudes, forms and behaves as predicted.

In application

The practical aspects of battery engineering to be explored by BEC customers include the automated installation of chemical products, and the disassembly or assembly of packs.

“Using a robotic arm, we can pick an applicator from a turret magazine – you can also call it a rotating tower – with eight different dispensing units,” Dr Lammerschop explains.

“The solutions we can dispense from those include both single- and two-part products, or also can be a flat, streaming product. Depending on what parameters it needs to fulfil, it can range from a polyurethane epoxy to a silicone or acrylic. But whatever the right material is, it can be picked and then robotically applied in series production conditions.”

Debonding of adhesives may be an even more crucial aspect of packs to be examined in the BEC in future. For packs and electric vehicles (EVs) to be sustainable, especially in cell-to-pack or cell-to-car designs – and also amid the growing trend of chemically encapsulated and bonded cells – the opening packs for repairs or overhauls must be technologically possible, without such services having a negative impact on the lifespan of the pack or the vehicle.

Thorough testing

Having applied the battery adhesives, lid sealants, thermal interface materials or other materials sought after by the customer, the pack can be taken through the BEC’s test facilities. Here, each pack can be electrically cycled, either in typical operational conditions or in extreme conditions. These can include fast-charging and -discharging, or extreme environmental temperatures and moisture levels, ranging from -40 to +90 C and 10-90% humidity.

“We can cycle batteries in a climate chamber, with either gentle gradients of heat and moisture, or put them through thermal shocks to complete the picture of the pack’s behaviour, and validate if the testing results support the projections that came up during the simulation phase,” Dr Lammerschop explains.

“In electrical cycling, we’re geared for fast charging and discharging of 800 V systems with up to 330 kWh, measuring how the Henkel products improve and influence overall car performance. Beyond this, we have partners through whom we can perform thermal runaways and other destructive testing to gain a clear picture of our products on battery safety performance.”

“Battery safety is also of very high interest to us for improving evacuation times for EV drivers in the event of a major issue, for which we can formulate new pack coatings, lid sealants, potting materials and other things that contribute to keeping passengers safe.”

A sustainable, digital future

Further BECs are in development, modelled upon the successful pilot one in Dusseldorf. Data and formulations collected in one BEC will be shared instantaneously via Henkel’s internal servers with the others across America, Europe and Asia. This will keep simulation, modelling and engineering capabilities optimised across all centres.

“Going forwards, we are investing r&d resources into key areas,” Dr Lammerschop says. “One is enabling new debonding technologies to make battery pack maintenance, repairs and overhauls less challenging, including a range of different ‘trigger mechanisms’ for quickly and efficiently disassembling bonded structures, such as applying a thermal trigger, liquid solutions or electrical debonding trigger.

“And, lastly, preventing thermal events requires more effective thermal management, including developing materials that provide both thermal and structural support to make better use of the finite volume and weight budget that today’s packs allow for non-cell components.”

On top of all this, Henkel is researching various avenues of sustainability in e-mobility, from cutting CO2 emissions in its production processes to increasing battery cell capacity by reducing cell resistance with conductive coatings.

By taking such measures from top to bottom, Henkel expects to uncover a variety of paths towards more sustainable battery design and production, with the results to be passed onto its customers’ products through the BECs in future.

Click here to read the latest issue of E-Mobility Engineering.

ONLINE PARTNERS