Quantix Ultra offers flame protection at 1,200 C

(Images courtesy of Freudenberg Sealing Technologies)

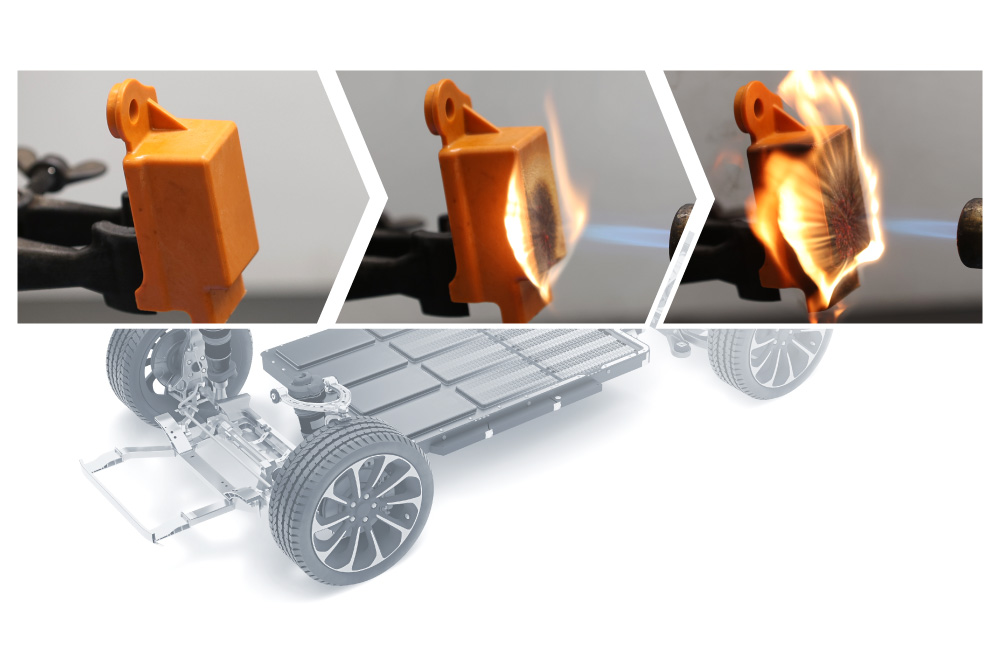

A new material called Quantix Ultra, produced by Freudenberg Sealing Technologies, offers improved fire protection in electric vehicle (EV) drives, having resisted temperatures of up to 1,200 C during testing.

From February 2024, it will be used for the first time by a car manufacturer in series production vehicles as a flame-protection barrier for the cooling system of lithium-ion batteries.

“The new material doesn’t melt at high temperatures. Instead, it exhibits elastic behaviour that can be compared to elastomers,” says Kira Truxius, materials expert in thermoplastics at Freudenberg Sealing Technologies.

“It also has a glass transition temperature that is 53 K higher, which means it retains its rigidity and flame protection over a significantly longer period of time. When you add up its qualities, Quantix Ultra is at the very top of all currently known plastics.”

Given that today’s vehicles call for lightweight construction, Quantix Ultra’s lower density, compared with metallic materials, is an advantage. Processing the material in injection molding is versatile and economical.

Strict testing standards

EVs with lithium-ion batteries require a high degree of safety. Various safety measures have been implemented to ensure any thermal runaway of the battery is prevented or delayed. So far, plastic components used for this purpose have generally failed to meet the automotive industry’s strict testing standards for electric drives.

However, Quantix Ultra can withstand very high temperatures. It does not melt or ignite. In lab tests, a 2 mm-thick material sample resisted an applied flame with a temperature of 1,200 C for more than 25 minutes.

Further tests simulated the emission of hot particles under high pressure, which can occur if the gases in battery cells are discharged abruptly. Quantix Ultra withstood the stress test for 20 seconds, whereas a 2 mm-thick aluminum sample took just two or three seconds to be destroyed.

Quantix Ultra material can also be processed into films for implementation in battery electric drives. Other usage areas include enclosures for power-supply units, media-carrying lines, cable insulation, battery housing covers and components for electric motors.

What is it?

Temperature resistance is an outstanding differentiating feature in engineering plastics. This applies to amorphous and semi-crystalline materials. But all currently used polymers have one thing in common: once the glass transition temperature is reached, their rigidity decreases noticeably and collapses abruptly when the melting point is exceeded – and flame protection ceases to exist.

The base material of Quantix Ultra is a thermoplastic that is already temperature-resistant. The addition of fillers such as glass or carbon fibres reinforces its mechanical stability, even under enormous heat. The additional cross-linking of the plastic molecular chains ensures the component maintains its shape, even under extreme conditions. Material properties can be adjusted according to the specific application. “Our patented know-how consists of the precise addition of suitable materials that create bridges between the molecular chains. The patents are the result of successful teamwork,” says Björn Hellbach, materials expert of thermoplastics at Freudenberg Sealing Technologies

Click here to read the latest issue of E-Mobility Engineering.

ONLINE PARTNERS