Fast-charging systems boost for UK motorways

(Images courtesy of Kempower)

In a much-needed push to enable greater uptake of EVs across the UK, charging systems manufacturer Kempower has been selected by UK-based Osprey Charging to supply fast DC charger infrastructure for more than 150 charging hubs due to open nationwide by 2025 (writes Rory Jackson).

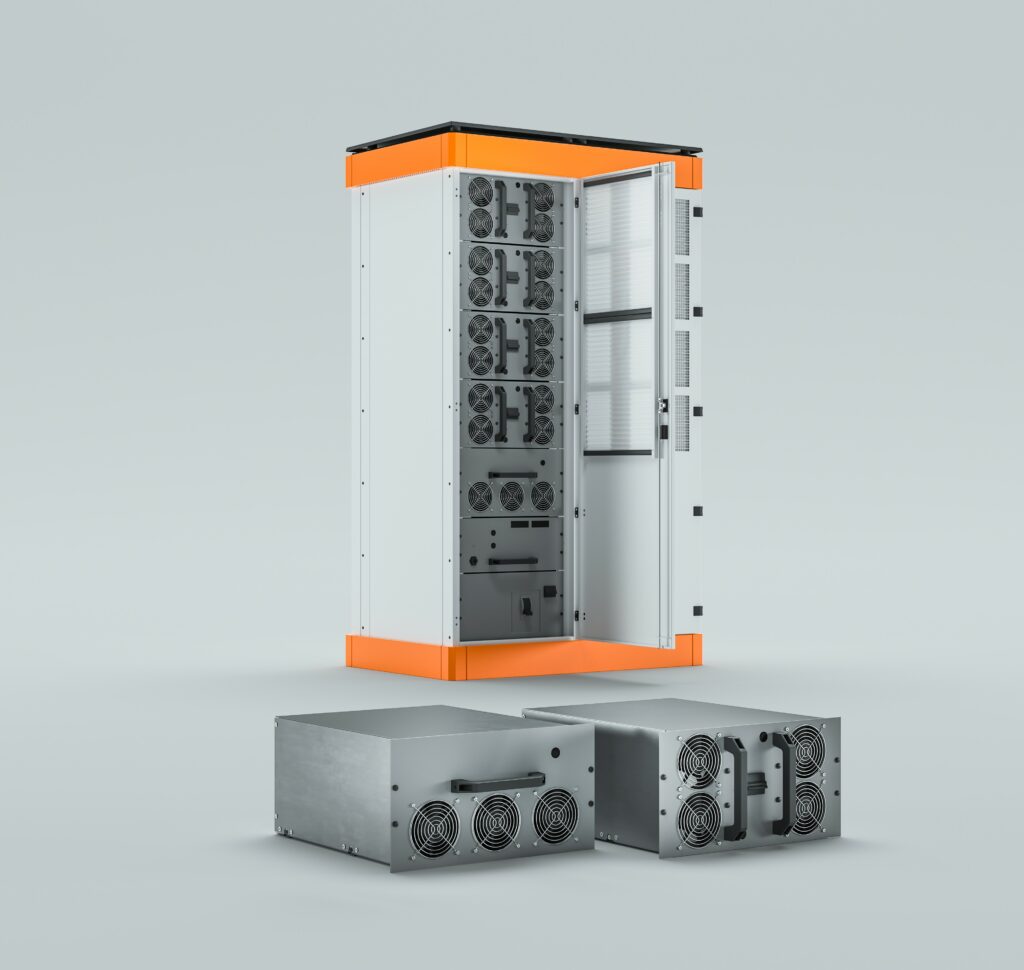

1500 units of Kempower’s charging systems will be delivered as per the £75m order, with up to 12 DC charging points per station, and each station will be strategically located on or close to motorways. Each system will consist of a combination of the Finnish company’s C-Station cabinets and S-Series charging posts.

In an exclusive interview with EME, Kempower CTO Mikko Veikkolainen comments, “Kempower was founded four years ago, but it was spun out of our sister company Kemppi, which has 70 years’ experience of manufacturing welders.

“Kemppi manufactured the world’s first inverter-based DC welding power source, in 1977, and we’ve transferred much of the electrical technology and knowhow used in their welding machines to our power modules and charging stations,” he explains, alluding to the highly complex arrangements of transformers, thermal management and control systems needed for efficient electric arc welding.

Kempower will distribute power to the EV charging plugs based on a hub-satellite configuration, with the C-Station cabinets acting as the hubs and the S-Series posts as the satellites.

“The satellites will mount the charging connectors and user interfaces, and through the interfaces customers can select their charging times and speeds,” Veikkolainen says. “The usage data is then transmitted wirelessly to the cabinets in real time so that [the cabinets] can scale up or down the power being distributed to each satellite in real time.”

Each 1000 V DC satellite is connected by a cable to a 480 V AC cabinet, which then connects to the grid. Each cabinet can integrate up to four 50 kW power modules (AC-DC inverters with silicon IGBTs for power conversion up to 95% efficiency) and connect with up to four satellites, thereby supplying power to up to eight charging connectors.

“By integrating four power modules, each C-Station cabinet can supply 200 kW across eight charging plugs,” Veikkolainen says. “If though, over time, that doesn’t seem to be enough and some charge points or stations are much busier than anticipated, or overtaxed by EV truck drivers replenishing their batteries for long hauls, we can just install more cabinets and have some satellite pairs ready for 400 or 600 kW.”

Each Kempower module is air-cooled and connects to two 25 kW power source inputs, with dynamic control over power distribution. This control system is intended to adjust for the instability of EV charging curves – Veikkolainen notes that most EV battery packs can take quite a lot of power to replenish their energy within the first 10 minutes, but that this tends to drop dramatically afterwards.

A given recharging session might therefore start with a 150 kW supply, with the cabinet allocating six power inputs across three modules to the charging cycle. After 10 minutes though, and based on BMS data coming from the EV and satellite, the cabinet’s charger controller might reduce that to 120 kW, releasing one power input which is then available for delivering power to another satellite or charger plug.

Each satellite is designed to support CCS2 and CHAdeMO plugs, and comes with an IP54- and IK10-rated enclosure, with electrical safety protections rated to IEC standards 61851-1 and 61851-23 as well as EN 61000-1, -2, -3 and -4 for EMC.

Veikkolainen adds that using a hub-satellite configuration is ergonomically useful for Osprey Power to construct new charging stations on older motorways that have limited roadside space. By powering and controlling the charging connectors remotely, the cabinets can be installed some distance away from the satellites, for example in a field much further from the road than the charging lot.

The HV cables are routed underground to prevent damage or tripping, and each cabinet has a 4G antenna for data comms with the satellites without the risk of EMI from the HV cabling. This ensures sufficient space for driving, parking and walking around each charging station, so that all vehicles and drivers can easily access charge plugs without the cabinets acting as obstacles.

ONLINE PARTNERS