Fasteners for EV assembly

(Image courtesy of Bossard)

Holding it together

Peter Donaldson assesses the relative strengths of the fastening techniques used in EV fabrication

Nuts, bolts and screws with standardised sizes and thread pitches were one of the most important technological developments in the history of manufacturing. Without them – and the wider field of fasteners that they represent – it is more than likely that mass production as we know it would not exist. Fasteners remain fundamental to mechanical design and manufacturing across all industries, e-mobility included, but they come with trade-offs, and some sectors are making efforts to minimise their use – or even eliminate them altogether.

Pros, cons and alternatives

(Image courtesy of the author)

Fasteners have many advantages. They support modularity by allowing systems to be built up from independent sub-assemblies, and aid serviceability by easing disassembly and reassembly for maintenance, repair and upgrades. Their load transfer properties are well understood, and they can handle tensile, compressive and shear loadings, making them suitable for structural joints and high-stress applications. They are particularly cost-effective for low to medium production volumes, compatible with existing tools and manufacturing processes, and easily stocked and readily integrated into production lines.

Because they are made to internationally recognised standards, it is easier to ensure that components made by different manufacturing tiers and separate contractors will fit together using the specified fasteners. However, the standardisation process remains ongoing in the e-mobility industry.

Reasons for wanting to get rid of fasteners are several. Reducing weight is critical in aerospace, particularly with electric aircraft, and in many road-going EVs such as cars and motorcycles. In high-speed automated manufacturing, the potential reductions in assembly time and cost enabled by eliminating fasteners are very attractive. Smoother surfaces can be more aesthetically pleasing and improve airflow or waterproofing, while fewer stress concentrations and reduced risk of loosening promise better durability and reliability. Getting rid of fasteners might simplify recycling and/or ease compliance with end-of-life legislation by using fewer mixed materials.

There are many well-established and improving alternatives for holding components together. Adhesive bonding, for example, is excellent for dissimilar materials, is lighter than fasteners and distributes stress more uniformly. However, it requires more surface preparation and curing time and is generally non-reversible, although adhesive formulators are working on de-bonding methods.

Welding creates strong, permanent joints ideal for metals used widely in automotive body-in-white and battery tray assembly, its principal cons being the need for compatibility of the materials being joined, potential thermal distortion of welded assemblies and the need to grind out or cut welded joints if they have to be reworked.

Snap fits and interlocking joints enable assembly without tools or with simpler tools on automated lines, reduce weight and work particularly well with plastics. However, the parts generally have to be made to very tight tolerances, and joints are often less strong than those that rely on fasteners.

Adhesive tapes and films are a commonly used option in automotive trim and electronics applications, providing very clean surfaces, but they are sensitive to extremes of temperature, ultraviolet light and surface contamination.

Perhaps the most spectacular technology that reduces the need for fasteners is gigacasting, in which very large, high-pressure die-cast aluminium parts replace complex sub-assemblies in vehicle structures, famously used by Tesla in front and rear underbodies. Gigacastings replace dozens to hundreds of welded, riveted or bolted parts with a single casting, eliminating many fasteners, welds and sealants, thereby simplifying the design and reducing the parts count.

Strategic decision

(Image courtesy of the author)

The principal take-away from all this is that the choice of joining methods is a strategic decision that should not be approached with an ‘all-or-nothing’ mindset. Many manufacturers combine methods, for example using rivets and adhesives together to optimise performance, speed and cost, and any move away from traditional fasteners is context-dependent and based on design goals, materials and product design lifecycles.

EVs use a wide range of fasteners that have considerable commonality with those used in ICE vehicles, but with added emphasis on electrical integrity, weight reduction, thermal management and vibration resistance. Very broadly, they can be categorised as mechanical, electrical and specialised fasteners, but there is often wide overlap between categories.

Mechanical fasteners include bolts and screws in standard sizes or as custom-designed items for high strength and low weight, which are often paired with nuts and washers that might include locking and vibration-resisting functions. Where permanent joints are required, or access is limited to one side of the materials to be joined, for example in battery trays and body panels, rivets are typically used. Clips and retainers used for wiring, trim and insulation components can also be categorised as mechanical fasteners.

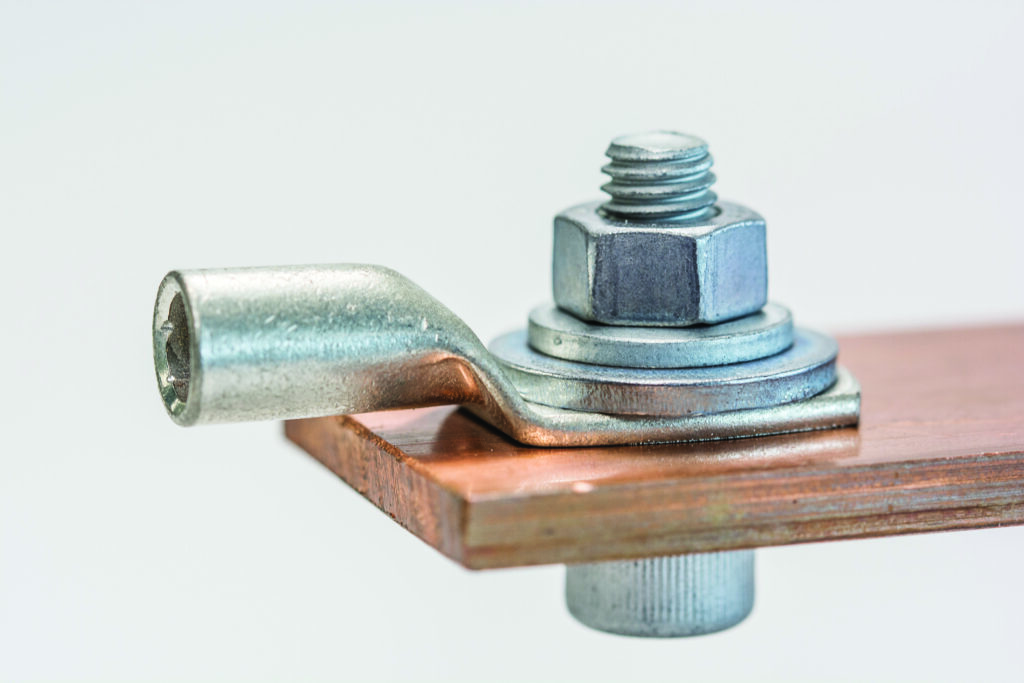

Electrical fasteners are used for connections in battery, powertrain and control systems, with high-conductivity bolts that often feature coatings to reduce resistance and inhibit corrosion, such as in securing busbars, while terminal lugs and eyelets join high-voltage (HV) cables to modules or distribution points etc. Weld fasteners, such as nuts and studs, are often used in battery packs with the fastener welded to sheet metal using processes such as capacitor discharge welding to provide securing points for internal components.

Fasteners tailored to EV-specific challenges fit that specialised category. These include plastic fasteners used where the required clamping forces are relatively small and the components are light, such as within vehicle interiors and mounts for small sensors. In contrast, heat-resistant fasteners, often made from stainless steel or treated alloys, are often used in areas near motors and inverters. Also included in the specialist category are fasteners with sealing features for protecting sensitive components from moisture, dust and other contaminants, such as those used in IP-rated enclosures.

Advancing fasteners

(Image courtesy of Stanley Engineered Fastening)

The fastener industry continues to advance its products, usually in close cooperation with its customers in the manufacturing sectors it serves. One key area of advancement is materials, which provides opportunities to reduce fastener weight without compromising structural integrity. Here, developers are exploring the use of advanced alloys of aluminium and titanium, and adopting high-performance composites to reduce mass while retaining strength. In structural applications, micro-alloyed steels and optimised geometries help achieve strength-to-weight advantages. Plastic and polymer fasteners are also being introduced for non-load-bearing uses such as cable routing and thermal insulation retention.

Although important, these trends are neither new nor limited to e-mobility, and many of the lessons learned in ICE vehicle applications inform EV manufacturing. Because there is no such thing as a ‘free lunch’ in physics, if the requirement is for high tensile strength, it typically pushes engineers to choose steel alloys, although lower weight and higher tensile strength can be achieved using magnesium and titanium alloys for a much higher price. This is usually unacceptable for standard fasteners, so the choice tends to revert to steel.

There are likely to be opportunities for aluminium alloy fasteners in EVs for weight saving, although there are other areas of the vehicle that could yield greater results in the short term, such as busbars for example. Switching from copper to aluminium for these components could provide much greater weight savings than those obtained by making a change to fastener materials.

One innovative use for aluminium is in weld studs that secure cooling lines and HV cables, which can also be designed as ground (earth) studs. Also, metal holders for such components can be replaced with polymer equivalents with high levels of recycled content.

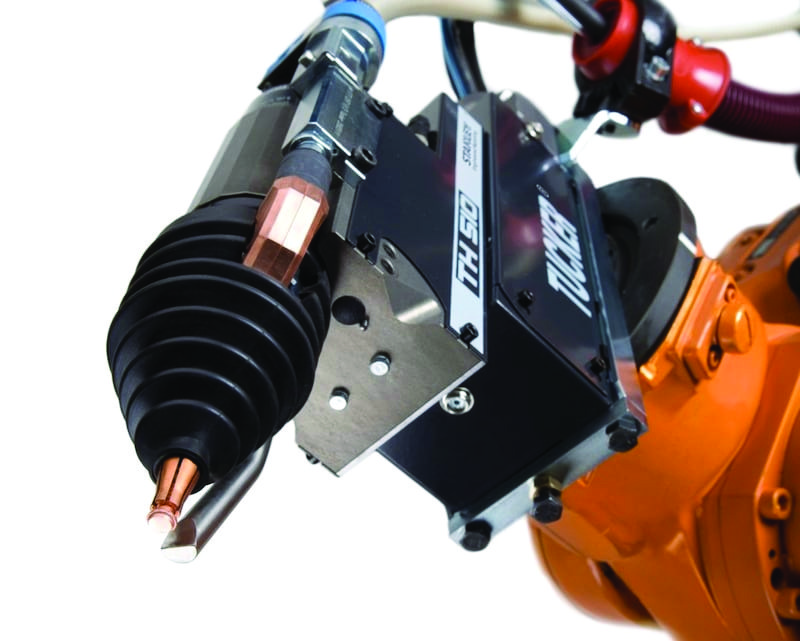

Another new technology is a type of plasma joining that enables small, light pins to connect structural parts in a way that requires relatively little installation space and potentially leads to weight saving in the fasteners and the entire battery housing. Needing access only to one side of the structure, the technique uses ‘plasma pins’ to penetrate temporarily softened sheet metal, enabling the joining of steels with tensile strength of up to 2000 MPa without need for a pre-drilled hole, and the pins can also be used to reliably join dissimilar materials.

Cost and weight reductions can also be achieved by supporting and routing wires, tubes and channels with small metal studs that are compatible with multiple types of plastic clip.

Fighting corrosion

(Image courtesy of Bossard)

Another perennial need is to prevent galvanic corrosion in fasteners joining dissimilar metals, such as when attaching aluminium battery enclosures to steel body or chassis structures. Galvanic corrosion occurs when dissimilar metals come into contact, owing to their different anodic potentials. The risk of galvanic corrosion is fairly low if the fasteners are used in clean, dry environments, such as inside a sealed box. However, if joints between dissimilar metals are exposed to moisture and aggressive chemicals such as salt, they can be affected by both galvanic corrosion and oxidation, which is the worst-case scenario.

To enable the base material to perform its function over the design life of the fastener, and perhaps that of the vehicle, engineers have the option of pre-applying surface finishes, coatings and/or sealants at the interface between the parts to be joined. All of these approaches come with their own design considerations and associated costs, which are important to understand.

Widely used coatings include zinc-nickel plating – favoured for its strong corrosion resistance and aesthetic appeal – and organic zinc flake or non-conductive barrier coatings. Alternatives such as dip-spin coatings offer excellent performance, particularly in harsh environments such as exhaust systems and other applications where there is exposure to moisture, chemicals and large temperature changes. Additionally, insulating washers or sleeves are used to electrically isolate dissimilar materials. Proper torque control and sealing are critical to minimise moisture ingress, which accelerates corrosion.

(Image courtesy of Bossard)

Expansion and contraction

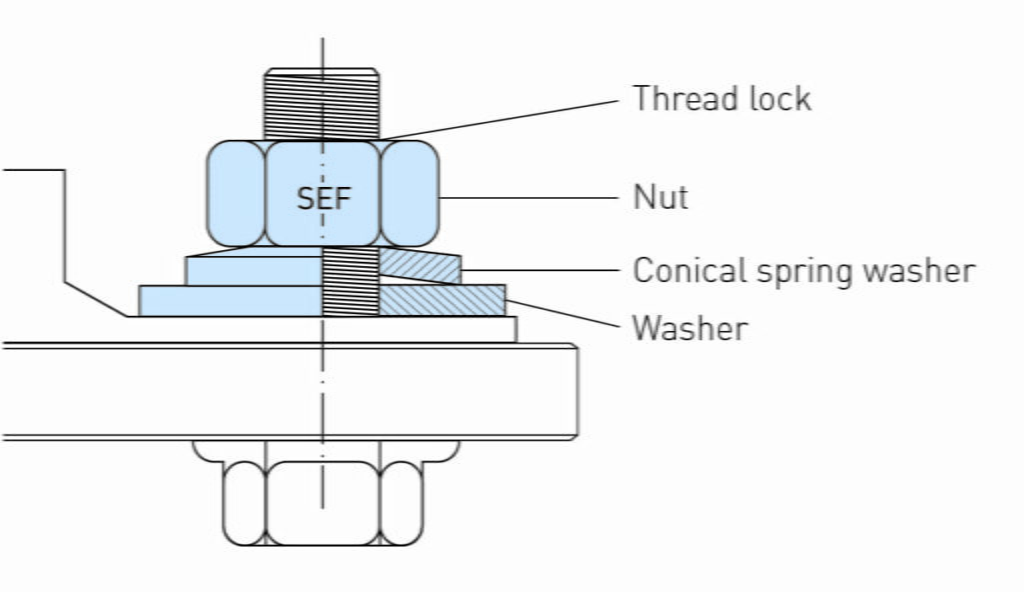

Fastener design also has a role to play in minimising the effects of mismatches in thermal expansion rates between different materials like those used in battery enclosures and power electronics assemblies. Managing thermal expansion in EVs – especially around high-current busbars – is a new and critical challenge. EVs generate sustained heat in conductive components, leading to significant thermal expansion. This makes fastener selection and clamp load control vital. If fasteners are too rigid, thermal cycling can cause excessive stress at joints, leading to cracking, warping or loosening, so fasteners designed with flexibility or elasticity can prevent these problems.

Perhaps counterintuitively, higher-grade fasteners aren’t always the best option. Over-torquing can deform components, leading to a loss of clamp load during contraction, which increases electrical resistance and risks thermal runaway. The goal is to achieve a clamp load that is firm enough to ensure conductivity (minimum 30 MPa), but flexible enough to accommodate thermal cycling. Standard torque tolerances must be respected; extra tightening is detrimental.

Features like conical (Belleville) washers are used to introduce elasticity into the joint, allowing it to ‘breathe’ with temperature changes and maintain clamp load. Likewise, bolts with refined designs of cupped washer can compensate for the movement caused by thermal expansion and contraction, maintaining consistent clamping force. Some designs use ‘floating’ or slotted fastener holes, allowing slight movement between joined parts as they expand and contract.

With fasteners that permit such movement, particularly in power electronics applications, insulating sleeves or bushings are often included to prevent short circuits.

Designers working on fasteners used in and around battery packs, in components such as busbars and terminal blocks, face several challenges that include maintaining low contact resistance, preventing oxidation and ensuring a stable clamping force over time. Material selection is crucial and choosing conductive coatings such as silver or tin over copper or brass is common. Designs must also prevent fretting corrosion in environments with vibration or thermal cycling.

Conductivity and resistance

(Image courtesy of Stanley Engineered Fastening)

Designing fasteners for such high-conductivity, low-resistance applications presents unique challenges. The primary objective is not mechanical strength but maintaining intimate, low-resistance contact between conductors. Achieving and sustaining the correct clamp load under all operating conditions is crucial, for which it is essential to understand the surface pressure generated beneath the fastener’s bearing surface area to prevent embedment. Additionally, the design must accommodate the expansion and contraction of the busbar itself.

To spread the clamp load over a wider area, fasteners must have larger heads and smaller thread diameters, diverging from typical mechanical fastener ratios (e.g., favouring a 4:1 or 5:1 head-to-thread ratio over the usual 3:1). However, forging such wide-headed fasteners, especially from alloy steels, is typically difficult and expensive. For example, material displacement during forging becomes harder to control, making production more complex.

A complementary approach is to design fasteners that can maintain high and consistent preload forces throughout vehicle operation and temperature fluctuations, often paired with defined technical cleanliness to guarantee consistent contact resistance.

Additionally, vibration resistance is important, particularly depending on the fastener’s location within the vehicle. Standards such as LV241 or USCAR2 define vibration levels (V1 to V5), with EV electrical components often falling into the V2–V3 categories, and harsher applications such as in-wheel motors requiring V5-rated fasteners. Ultimately, both form and function must align with the fastener’s intended environment and electrical purpose.

Supporting thermal management

In thermal management, fasteners have an important supporting role in that they help overall heat transfer by ensuring uniform pressure distribution across thermal interface materials (TIMs). An appropriate clamping force ensures intimate contact between surfaces, minimising air gaps and maximising thermal conductivity. Proper fastening also ensures flatness and contact with cooling plates. Well-designed fastener systems allow for easy disassembly and reassembly, ensuring that thermal management components (including cooling plates and TIMs) can be serviced or replaced without compromising thermal performance.

Alloys or plastics with high thermal conductivity, combined with thermally optimised fastener paths, can be used to conduct heat away from critical areas. Furthermore, engineers are now exploring fasteners that support active cooling, such as those that allow liquid coolant to flow through or around them, similar to banjo bolts used in hydraulic systems. Although still in the early stages, this approach is gaining relevance as systems evolve toward high-power, high-current applications.

In the HV regions of EV powertrains, fasteners with integrated insulation are essential safety features. Design elements might include integral insulating washers, gasket layers, ceramic coatings or plastic sleeves, and material combinations such as metal-plastic hybrids for HV terminals and overmoulded metal components. Insulated fasteners are used primarily for touch protection in HV applications, such as EV busbars. They are typically rated for up to 1000 V, which provides sufficient margin for 400–800 V systems.

Different vibes

While EVs generally provide a smoother ride than ICE vehicles, they are affected by vibration. EV vibration is typically characterised by high frequencies and low amplitudes generated by e-motors, contrasting with the lower-frequency and higher-amplitude vibrations associated with ICE vehicles. Testing typically involves multi-axis vibration, thermal cycling and combined environmental testing to replicate EV-specific conditions such as road vibration and regenerative braking loads. Fasteners are evaluated for torque retention, fatigue performance and clamp load stability using accelerated life testing protocols.

Simulations help predict how a fastener will behave under different conditions, factoring in conditions such as load, vibration profiles and thermal analysis, thereby allowing industry to optimise a design before investing in prototype and production equipment. Furthermore, fasteners are also simulated and tested as parts of complete assemblies.

Because there are currently no dedicated standards for EVs – although this situation is changing – industry tends to use established norms such as DIN 65151 and GMW 3172, adapted with EV load requirements from OEMs.

Validation of fasteners for vibration resistance in EVs typically falls under V2–V3 classifications, depending on the installation location within the vehicle. Existing standards, such as USCAR-2, are mainly geared toward low-voltage, low-current systems, prompting the development of new, more relevant standards – particularly in Germany (VDI) and China – to accommodate the higher voltages and currents in EVs. These new standards aim to provide consistent, realistic requirements without over-engineering, which can lead to unnecessary costs. Proper standards also help ensure supply chain consistency, consumer confidence and legal accountability, much like ISO 898 in the mechanical fastener domain. As EV designs evolve and undergo value engineering, having clear and enforceable standards becomes crucial to prevent quality or safety compromises while controlling costs.

Hold tight

There is a wide array of solutions to prevent loosening in high-stress EV applications. These can include such solutions as pre-applied adhesives, serrated or knurled flange heads, locking inserts and wedge-lock washers, which are effective in vibration-rich environments. The latter use surface ramps on the bolt head or nut face and a mating washer that lock together to maintain the clamping force needed to prevent loosening.

Thread-locking technologies offer several well-known options including serrated washers and chemical solutions like thread-locking compounds. Also, thread geometries can be used to eliminate the clearance between male and female threads, locking them together.

One refinement of this idea uses a specially profiled internal thread geometry in the nut to create locking resistance only at the final clamp load stage. This provides secure fastening without increasing prevailing torque during installation, unlike traditional lock nuts or displaced-thread designs, which resist rotation from the start.

Another approach for when even greater robustness is needed is to use swaging rather than torque to engage a collar and pin. This mechanically deforms the collar to create an interlocked joint that allows the collar to stay in place for ease of pre-assembly and then fills the helical thread for strength and vibration resistance.

For mission-critical applications, load-sensing or smart fasteners that detect preload loss are emerging to support predictive maintenance strategies.

Ensuring electrical continuity or isolation in fasteners for HV battery and power electronics systems is essential. For fasteners that must conduct electricity, in earth connections for example, highly conductive metals such as copper and aluminium are used (taking corrosion compatibility into account), with conductive finishes such as nickel and silver applied to reduce resistance, together with a design-maximised contact area for optimal current flow.

For fasteners that must prevent conduction, such as those securing insulated components or isolating conductive parts, non-conductive plastics are effective, as are insulating layers of polymers, such epoxies or PTFE applied to metallic fasteners, and insulating washers, bushings or sleeves. Design elements that support these measures include keeping fasteners out of the arc range from conductive surfaces through use of insulating barriers or spacers. Testing focuses on dielectric strength to validate isolation at high voltages.

Automation-friendly fasteners

Whenever automation is involved in an assembly line, it’s crucial to consult with a fastener engineer because their expertise helps identify common pitfalls and ensures proper quality control measures are in place to prevent line stoppages.

Automated production presents challenges for installation of fasteners, often necessitating the use of specialised items such as self-piercing rivets, flow drill screws and one-sided access blind fasteners, which are better suited than more conventional items to robotic installation and high-speed assembly. These technologies offer repeatability, reduced pre-drilling requirements such as pilot holes, and compatibility with mixed-material stacks. Some are used in tandem with structural adhesives for added strength and NVH benefits.

Fasteners suited for automated EV production must balance precision, speed and material compatibility. Traditional drilled-hole fasteners offer high positional accuracy but tend to slow production. Alternatives like self-piercing fasteners or self-tappers improve speed but slightly compromise placement accuracy – acceptable in many mass-production scenarios. New developments focus on press-in fasteners that require no pre-drilled holes or adhesives. These fasteners create mechanical interlocks by deforming the base material under pressure, allowing fast, clean installation even on conductive surfaces like busbars. Such designs are ideal for low-load applications such as securing voltage or temperature sensors, where surface integrity and ingress protection are crucial. Some variants also offer higher mechanical performance for use in structural areas such as battery trays. These technologies support fully automated assembly lines, reduce part preparation and eliminate the need for adhesives or sealing, making them well-suited for high-speed EV manufacturing where performance, simplicity and protection against contamination are essential.

Increasingly, automated manufacturing systems must handle assembly of components and structures that combine several different materials, and using fasteners that support this process are essential. One solution is flow-tapping screws that can join composites, plastics, aluminium, steel and other materials without need for pre-drilling. Advanced versions need only low pressure to install them, and take around 1.6 s to drill through metal with thickness of up to 7 mm. Typical areas of application include battery packs, bumpers, window frames, B pillars, door sills and tailgates.

Self-piercing rivets (SPRs) represent another option widely used in EV production because of their ability to join dissimilar materials, such as aluminium and high-strength steel, again without need for pre-drilled holes. SPRs are compatible with robotic tooling, work well with lightweight materials, and create durable joints even under dynamic loads and vibration. Furthermore, installing them requires no heat, thereby reducing energy consumption and thermal distortion.

In applications such as securing fire protection materials on the top and bottom of battery boxes, for example, they don’t need curing time, as is the case with adhesives, and they provide better gas-tightness than that offered by flow-drill screws thanks to the lack of pre-drilled holes.

Automated installation of grounding (earthing) studs is aided by ‘no-hole’ studs made from steel that can be welded to all automotive steel grades including advanced high- and ultra-high strength types. Likewise, aluminium ground studs are available that can be welded to all grades of aluminium, including castings. In the latter case, plasma cleaning might be needed to provide ideal surface conditions for the weld.

Blind rivet nuts take advantage of the ability of the blind riveting process to fasten layers of material together with access from one side only, and provide an internal thread for a bolt. Some advanced designs also have a mechanical sealing feature that eliminates the need for O-rings or under-flange moulded sealants. Automated installation of blind rivet nuts is a recent innovation.

Focusing on the battery box, it’s important to prioritise reducing complexity to decrease cycle times while maintaining high quality. This can involve using thread-forming fasteners or multifunctional fasteners that integrate sealing features and assembly aids to streamline the process.

Speeding assembly

Optimising for reduced assembly time while maintaining structural integrity involves selecting fasteners that support automated feeding, self-aligning features and minimal installation steps. Use of captive washers, integrated locking features and standardised thread sizes also helps streamline processes while ensuring repeatable joint strength.

Broadly, those fasteners best suited to minimising assembly time include self-tapping screws, which are perhaps the simplest and don’t need pre-drilled holes. There are also thousands of varieties of break-stem, speed rivets and structural rivets, while plastic fasteners paired with no-hole welded studs are quick and easy to assemble once the stud is placed. Pre-assembled fasteners come with integrated washers or captive components, reducing the number of small parts to be managed throughout the assembly process. Lastly, snap-fit fasteners have mechanical interlocking features that enable rapid tool-free assembly.

Maintaining structural integrity relies on factors such as fastener material selection and thread design, opting for threads that maximise the clamping force and resist loosening under vibration. Corrosion resistant coatings and surface treatments help maintain structural integrity through long service lives in harsh environments, while load distribution features such as flanges and integrated washers prevent localised stress concentrations.

Fasteners that are friendliest to robotic handling are most compatible with automated assembly, and are characterised by consistent geometries and self-aligning features. Those that can be pre-loaded into automated tools for fixtures help minimise manual handling.

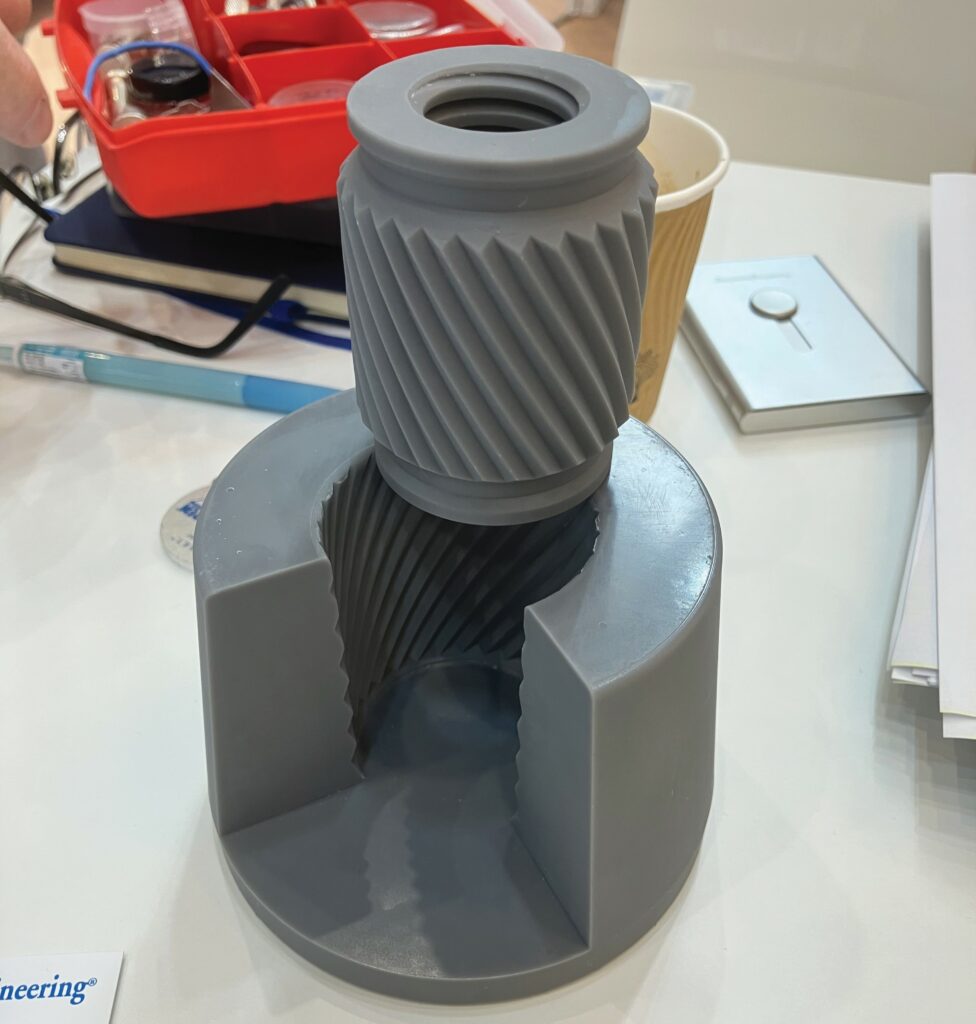

Traditional screws can slow production processes owing to the need for precision, torque control and surface preparation. Technologies such as press-fit spiral fasteners offer a high-performance alternative. Advanced examples install in under a second – versus up to three seconds for screws – and provide similar clamp loads to those of M5 steel screws in aluminium. Advanced press-fit spiral fasteners require no drilling, tapping or hole preparation, working even in ‘as-cast holes’ with draft angles. This makes them ideal for high-volume, automated production lines. Unlike screws, their performance improves simply by increasing their length, enhancing engagement without changing the material grade or diameter.

Designers are also adapting fasteners to automated assembly lines by making them inherently compatible with robotic tools through incorporation of robot-readable orientation marks, anti-cross-thread designs and low-friction starts to aid in automated insertion. Packaging formats such as tape-and-reel or bin sorting systems also support seamless integration into high-throughput assembly environments.

Increasingly, fasteners are being adapted for automated assembly lines and robotic tooling as manufacturers move toward lights-out manufacturing and Industry 4.0 practices. Companies are developing auto-feeding and auto-installation systems that integrate fasteners directly into robotic heads or progressive presses, enabling fully automated processes with minimal human or even robotic intervention after installation. For example, in-die feeding installs fasteners during stamping operations, producing a finished component straight from the press.

Designs optimised for rapid assembly minimise the number of fasteners needed through use of multi-functional or consolidated components, together with standardised fastener types and sizes to simplify both inventory management and assembly processes. Also, ensuring that fasteners are easily accessible and oriented for efficient installation, especially in automated systems is essential.

Over the next three to five years, greater emphasis on multi-functional fasteners, sensor integration and eco-friendly coatings can be expected. Innovation will probably be driven not by basic functionality – which is now largely resolved – but by value engineering and optimisation. EV OEMs want to move quickly because as their technology matures, cost pressures are rising. This requires fastener suppliers to respond quickly to changing customer needs.

Acknowledgements:

The author would like to thank the following for their help with this article: Jon Dabney, director of automotive sales and engineering at Bossard North America; Bernd Brecheis, sales, product development & programmes director, Germany, at LISI Automotive; John E. O’Brien, global technologist, PennEngineering; Dezarai Shepherd, EV battery innovation lead, Adam Forti, global business development engineer, Stefan Schneider, director business development and Elena Schneider, EV battery thermal innovation manager at Stanley Engineered Fastening.

Some suppliers of fasteners

Acument Global Technologies

ARaymond

Arnold Umfordtechnik

Atotech

Bossard

Celo Screw Technology

EJOT

Growermetal

Hafren Fasteners

ITW Automotive

Kamax

Nord-Lock

Norm Fasteners

Optimas Solutions

PennEngineering

Sherex Fastening

Spirol

Stanley Engineered Fastening

SurTec

TR Fastening

ONLINE PARTNERS