Advanced data acquisition powers safer, smarter EV battery and powertrain testing

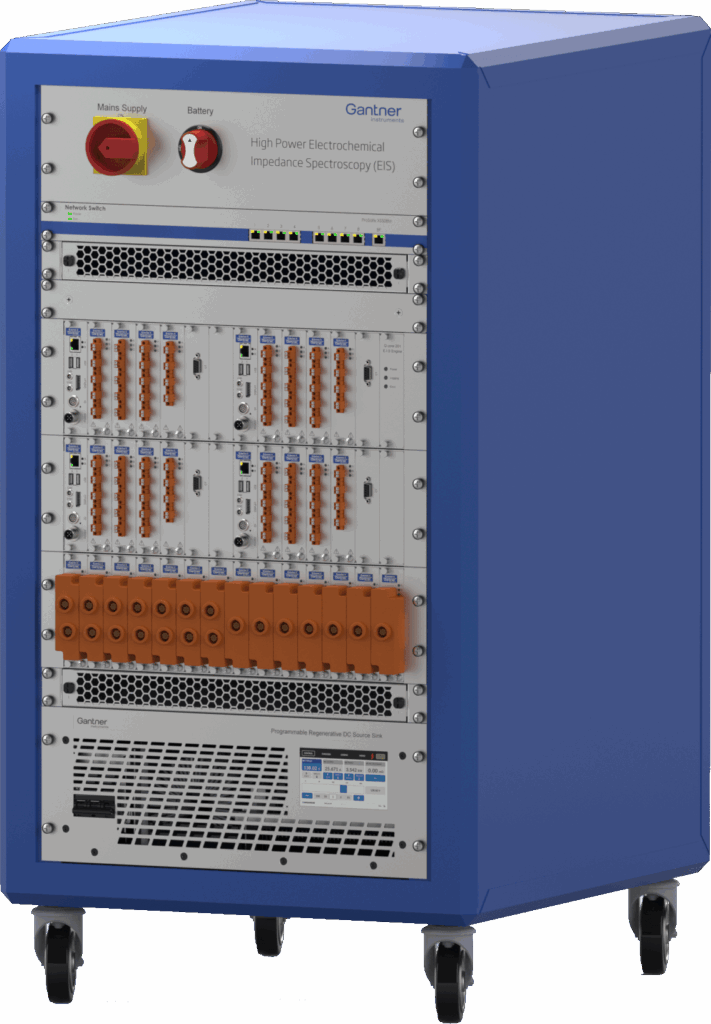

(Image courtesy of Gantner Instruments)

As manufacturers push the boundaries of EV battery technology and powertrain design, the demands on testing systems have never been greater. Engineers now require solutions that deliver not only precision but also real-time insights, seamless integration, and scalability across diverse testing environments, writes Peter Donaldson. Gantner Instruments (GI) offers high-voltage data acquisition and advanced power analysers to meet these challenges.

“Battery safety remains a top priority, with thermal runaway and mechanical failures posing significant risks. Traditional data acquisition (DAQ) systems often fall short in capturing the full picture during abuse testing. Battery failures can happen in milliseconds during penetration or short-circuit testing, for example, emphasising the need for synchronised high-speed measurements and visual proof,” according to a company expert. GI’s solutions integrate high-voltage DAQ systems with video recording, ensuring every frame is time-aligned with electrical, thermal, and mechanical data. “With sampling rates up to 4 MHz and noise performance optimised for potentials up to 1500 VDC, these systems provide engineers with the accuracy and clarity needed to pinpoint failure modes and improve designs,” the spokesperson adds.

(Image courtesy of Gantner Instruments)

EV powertrains operate at higher voltages and faster switching frequencies, challenging traditional power analysers. Inaccurate measurements can lead to missed optimisations, reducing overall efficiency. Advanced power analysers now offer ultra-low noise floors and 4 MHz sampling rates per channel, enabling real-time electrical and mechanical power analysis. “GI’s systems support triggered data logging and direct access to raw values, ensuring engineers can fine-tune powertrain performance with confidence.” Open interfaces and compatibility with multiple protocols, like EtherCAT and CAN-FD, further simplify integration into test benches and production lines.

As battery technology diversifies—from solid-state cells to high-capacity packs—impedance analysis and voltage monitoring become increasingly complex. Many DAQ systems struggle to scale, forcing engineers to juggle multiple platforms. GI approaches this with scalable electrochemical impedance spectroscopy (EIS) solutions, which provide a unified platform for testing at the cell, module, and pack levels, with synchronised measurements for temperature, strain, and voltage. “This enables real-time tracking of battery ageing and performance degradation, even under extreme charge or discharge conditions,” the company highlights.

Meanwhile, quiescent current measurement has emerged as a critical focus area. Modern electric vehicles rely on hundreds of ECUs, sensors, and electronic subsystems that continue drawing power in standby mode, the report highlights. “Microampere-level precision is essential to identify hidden power drains that impact battery longevity and vehicle range.” GI’s systems offer real-time detection and automated end-of-line testing, helping manufacturers meet stringent efficiency targets.

The future of EV testing lies in modular, scalable solutions that combine high accuracy with seamless integration. Open interfaces, intelligent data compression, and remote synchronisation (e.g., using PTP) are no longer optional—they are necessities for keeping pace with evolving standards. As the industry races toward higher performance and stricter safety requirements, engineers must rely on advanced DAQ systems that deliver uncompromising precision and adaptability.

Click here to read the latest issue of E-Mobility Engineering.

ONLINE PARTNERS