Reference design aimed at e-bikes

Efficient Power Conversion (EPC) has developed an inverter reference design based around an integrated gallium nitride (GaN) chip that reduces the size of powertrains in electric bikes (writes Nick Flaherty).

The design, for a 1.5 kW three phase brushless DC motor drive inverter, uses the EPC23101 eGaN chip. This has an embedded gate driver function and a floating-power GaN FET with an on resistance of 3.3 mΩ RDS(on).

The design, called the EPC9173, operates on an input supply of 20-85 V and can deliver a peak current of up to 50 A. This voltage range and power level makes it suitable for motor drives in e-bikes, scooters and city cars.

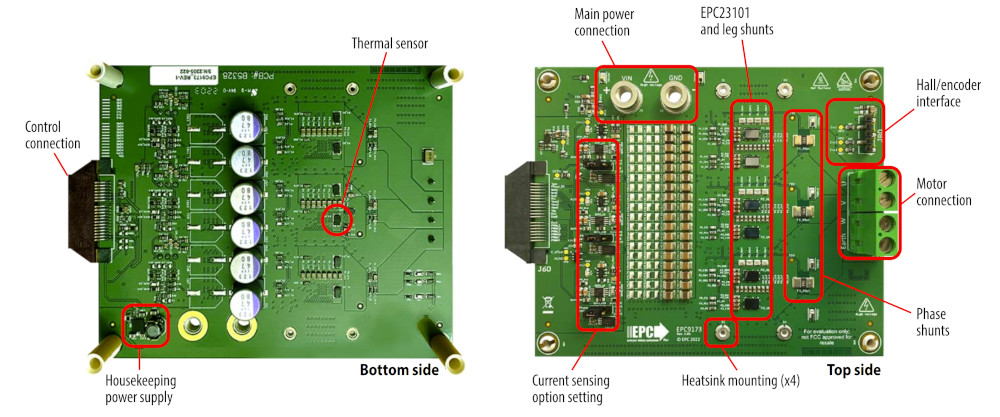

It contains all the necessary circuits to support a complete motor drive inverter, including gate drivers, regulated auxiliary power rails for housekeeping supplies, voltage, temperature and current sensing, and protection functions.

The board in the EPC9173 measures 130 x 100 mm and includes a 40-pin connector to provide power, PWM signals and analogue feedback signals between the interface control board and the EPC9173. There are versions for multi-phase DC-DC conversion topologies including Buck, Boost, half-bridge, full-bridge and LLC.

The GaN chip operates at up to 250 kHz, higher than for a silicon driver and power switch, which reduces the deadtime in the motor drive control to less than 30 ns. This helps to increase the efficiency of the motor with lower distortion for lower acoustic noise, lower current ripple for reduced magnetic loss, lower torque ripple for improved precision, and lower filtering for lower cost and a smaller footprint.

The EPC9173’s smaller size solution enables incorporation of the drive into the motor housing and supports low-inductance, higher power-density motors. When configured for a frequency of 100 kHz, the size of the input filter and the number of capacitors can be reduced, eliminating electrolytic capacitors from the board that can impact reliability.

The reference design enables phase current sensing and leg shunt current sensing. EPC provides full demonstration kits, which include interface boards that connect the inverter board to the controller board development tool for fast prototyping.

ONLINE PARTNERS