ENNOVI unveils flexible prismatic battery system

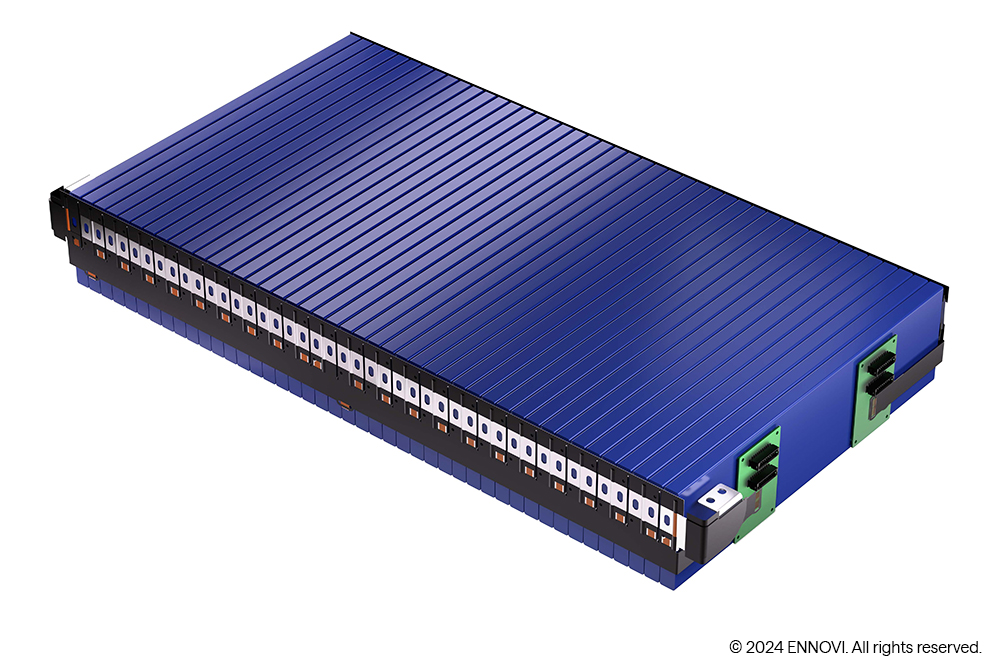

ENNOVI has launched the CellConnect-Prism, a prismatic battery cell contacting system that aims to redefine the connectivity and efficiency of battery modules.

The product gives engineers flexibility by enabling the seamless integration of individual prismatic cells to create larger battery modules, or advanced cell-to-pack (CTP) and cell-to-chassis (CTC) configurations. By streamlining the assembly process and eliminating inefficiencies, it accelerates battery pack production while optimising material usage and cutting costs.

One of the key innovations of ENNOVI-CellConnect-Prism is the adoption of a die-cut circuit (FDC) as an alternative to the conventional, flexible printed circuit (FPC). This reel-to-reel process reduces production time and costs while minimising environmental impact.

Additionally, the use of automotive-grade PET material and hot-bar soldering ensures optimal thermal resistance and component attachment.

The product eliminates the need for traditional insulation methods by integrating voltage and temperature sensing directly into the assembly, maintaining the highest standards of reliability and safety.

Compatible with prismatic, cylindrical and pouch cell formats, this versatile platform offers unique customisation options for diverse applications.

Randy Tan, product portfolio director for battery platform development solutions at ENNOVI, says: “Traditionally, prismatic cell contacting systems have relied on current collector assembly (CCA) technologies, which often suffer from inherent inefficiencies… ENNOVI-CellConnect-Prism revolutionises this approach by introducing innovative features that enhance performance and sustainability.”

Click here to read the latest issue of E-Mobility Engineering.

ONLINE PARTNERS