Elkem develops iron-silicon powder for 3D printing of e-motor parts

Elkem has developed a new, specialised iron-silicon powder, which may allow the 3D-printing of components for electrical motors, with partners through an EU-funded project.

Elkem’s partners in the SOMA (Lightweight solutions for e-mobility by AM of soft magnetic alloys) project are VTT (coordinator), Siemens, Stellantis and Gemmate Technologies.

Electric motors are generally made by cutting and moulding pieces from a metal sheet. While 3D printing can radically increase efficiency and reduce material consumption, outputting larger motor parts has proven difficult as they become brittle and can break easily.

The new powder is ‘soft magnetic’, meaning that it is easy to magnetise and de-magnetise.

“This is a project with potential to transform motor-parts manufacturing. We have created a new, specialised powder with good printability, based on silicon-steel (with additives). 3D-printed components show enhanced ductility and competitive magnetic properties,” said Tomi Lindroos, research team leader at VTT.

The powder is produced in a small-scale pilot atomiser at the Future Materials Norwegian Catapult Centre in Kristiansand, Norway.

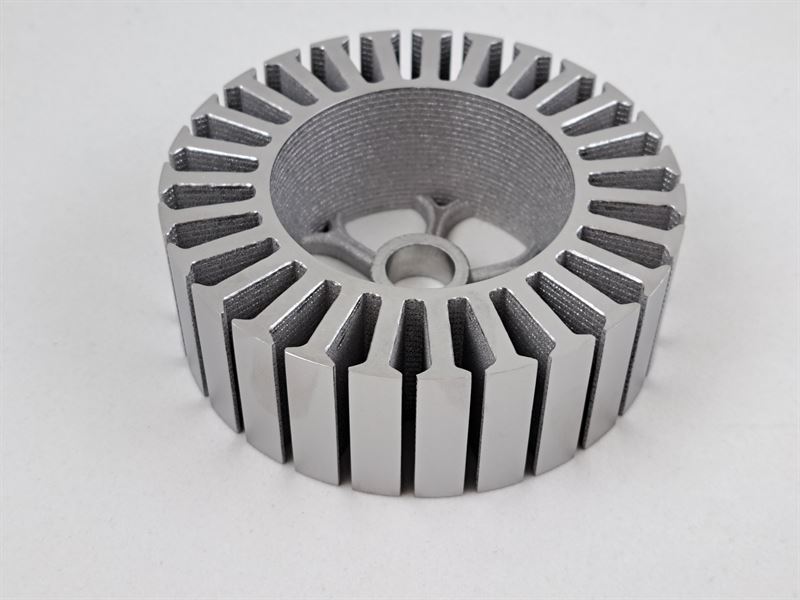

It has been used to 3D-print components to evaluate the quality and manufacturing of demo devices. The 3D-printing and part qualification was done at VTT in Finland and at Siemens in Germany.

The final use case was to produce a motor for an e-scooter, supported by modelling by Gemmate-Technologies and VTT, giving more novel design opportunities for components.

“The powder developed in the SOMA project will now be introduced to the market by Elkem for evaluating the product for future commercial production. The product is currently available in small test volumes,” said Jan Ove Odden, project leader at Elkem.

Click here to read the latest issue of E-Mobility Engineering.

ONLINE PARTNERS