Eaton secures OEM deal for SQ8 connector in new PHEV

(Image courtesy of Easton)

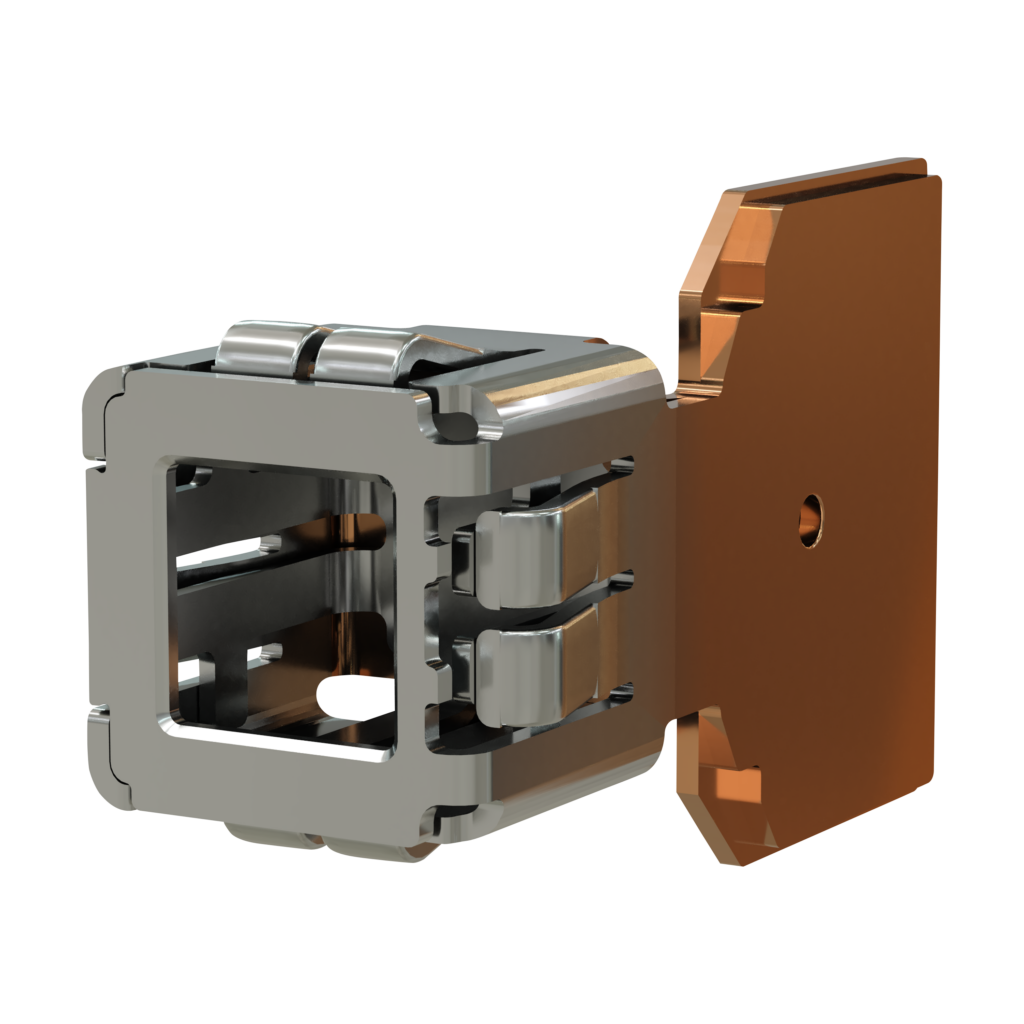

Eaton has secured a significant supplier agreement to provide its High Power Lock Box (HPLB) SQ8 connector system to a major global OEM for deployment on a new plug-in hybrid vehicle (PHEV) platform. This marks the first use of Eaton’s SQ8 configuration in a PHEV application.

The SQ8 connector is the result of extensive development in high-current, harsh-environment connectivity, offering innovations in both electrical performance and durable terminal architecture. The system’s patented inverted terminal contact system comprises a two-piece construction that separates the functions of conductivity and spring tension. Where conventional terminals rely on copper to provide both current carrying and spring action, Eaton uses stainless steel spring elements to maintain stable contact force after repeated thermal cycling, with copper exclusively for current transfer. This targeted design eliminates common failures arising from mechanical relaxation under high-vibration conditions typical of electric and commercial vehicles.

Internal benchmarking and analysis against published competitor data highlight the SQ8 terminal’s advancements. Testing demonstrates a 25 to 35 percent improvement in current-carrying capability per wire size and, more notably, 30 to 60 percent increased current delivery per unit volume. This directly enables more compact, power-dense solutions for vehicle manufacturers aiming to reduce overall platform weight while maintaining distribution efficiency.

Supporting up to 270 amps, the connector system maintains negligible resistance across its range, making it suitable for battery disconnect units (BDUs), propulsion circuits and high-voltage heating applications within both automotive and commercial EV sectors. In contrast to legacy bolt-and-nut assemblies, which require tools and can contribute to operator fatigue through high insertion forces, Eaton’s HPLB SQ8 features a secure push-click-pull mating mechanism requiring less than 75 newtons of force.

The connector provides consistent engagement with eight spring-loaded contact points for reliable connectivity. It accommodates wire sizes from 25 mm² to 70 mm², integrates flexible 90-degree and 180-degree terminal orientations, and bears USCAR-2 T3/V2/S3 validation in accordance with USCAR and ISO safety standards. Durability metrics include tolerance up to 125°C, vibration resistance to V2 grade, and rating for up to 10 mating cycles. QR code part traceability strengthens logistics and quality assurance processes for OEMs.

Having originated in commercial truck platforms and high-current heating systems, Eaton’s HPLB family, particularly the SQ4 and now the SQ8 variant, has demonstrated readiness for rapid scaling as vehicle electrification trends intensify. With the automotive market demanding greater current handling in smaller package envelopes, Eaton is advancing toward vertical integration for HPLB, targeting rising OEM interest, especially among teams addressing battery disconnect units and high-voltage subsystems.

Click here to read the latest issue of E-Mobility Engineering.

ONLINE PARTNERS