Dürr announces new approach to paint shop energy efficiency

(Courtesy of Dürr)

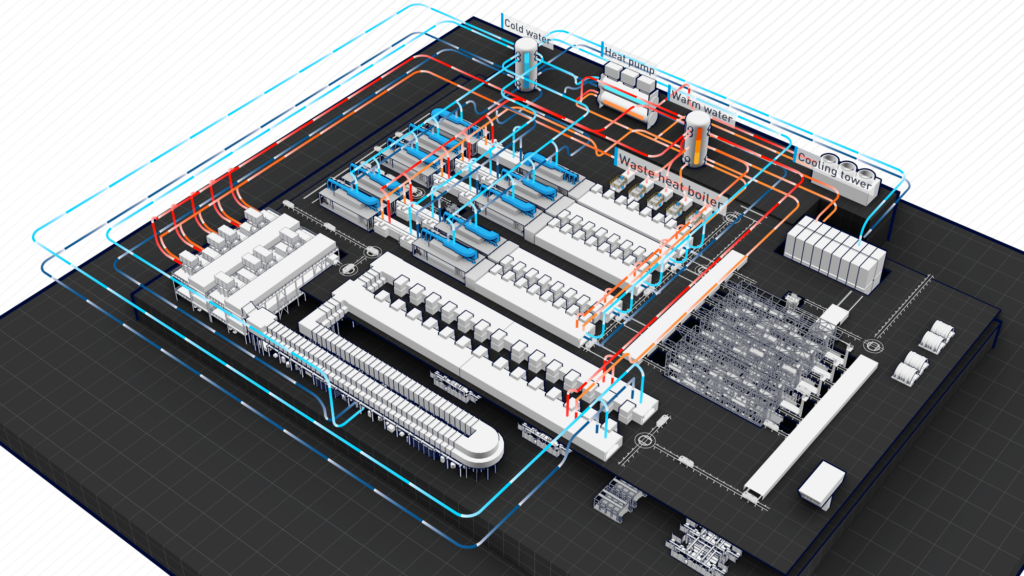

Dürr says its EcoQPower system uses energy flows in a completely new way to make automotive paint shop operations as energy-efficient as possible, by allowing plant operators to move towards electrification. EcoQPower is said to offset the additional electrification costs by reducing paint shops’ total energy consumption – by up to 19% in an initial customer project.

Networking all the elements boosts their efficiency, and almost no energy is left unused. The networks can be likened to a paint shop’s ‘nervous system’, redirecting the heating and cooling flows from one process area to another. Instead of supplying each area – paint booth, oven or pre-treatment zone for example – with energy individually, each one receives only the exact amount of energy it needs.

Each process receives not only the right amount of energy but also at the required temperature, making it possible to exploit previously unused waste heat sources. For this, Dürr has developed software that determines the heating and cooling requirements, in the form of a source/sink profile. This also considers the climatic site conditions and data such as production capacities, vehicle types and available energy sources such as geothermal or solar thermal energy.

Recognising which waste heat sources can be used for what makes it possible to take advantage of synergies from the processes and to select the right hardware components for the intended purpose, whether it be heat pumps, hot and cold water tanks, or a cooling tower.

ONLINE PARTNERS