CSM launches HV breakout modules with PowerLok connector system

(Images courtesy of CSM)

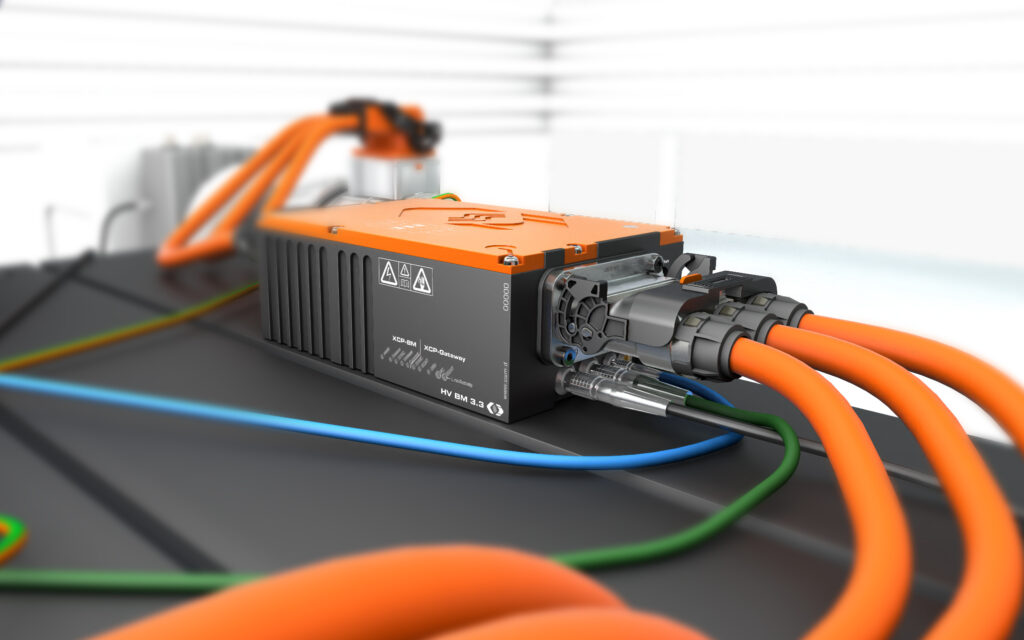

Measurement technology supplier CSM has unveiled two ‘C’ (Connector) variants of its high-voltage breakout modules (HV BMs) for measuring current, voltage and power in EVs. The company says a PowerLok connector system allows the modules to be connected simply and safely to reduce the time required for measurement set-ups.

The HV B M 1.2C is connected to HV power cables using a PL500 system, and allows single-phase measurements on separate HV+ and HV- cables. Similarly, but with a PL300 connector, the HV BM 3.3C can be connected to HV cables such as those between inverters and electric motors.

The HV BM 3.3C measures voltages U12, U23, U31 and internal conductor currents of L1, L2 and L3 with a measurement data rate of up to 2 MHz per variable. The measurement data is transferred to computer via CAN and EtherCAT (HV BM 1.2C) or XCP-on-Ethernet (HV BM 3.3C).

The PowerLok connectors are designed to operate with currents of up to 800 A. They include a quick-lock lever with a connection position aid and a socket housing with integrated high-voltage locking for high vibrations. When mated, the connectors provide IP67 protection. The connectors are also suitable for a high number of mating cycles.

Appropriate crimping tools are available for attaching the appropriate connectors to the HV cables. This also allows connectors to be attached to cables on site.

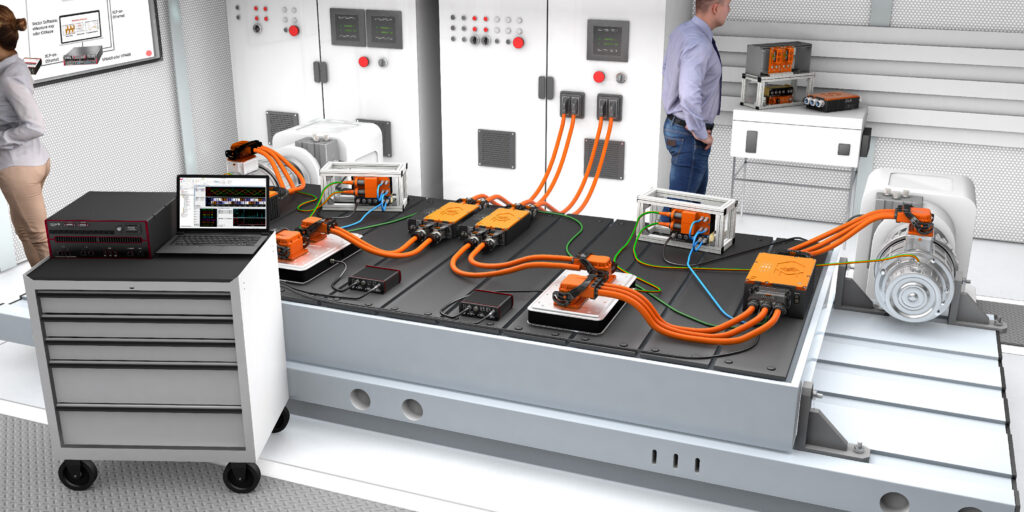

As electromobility continues to develop, new components are constantly being integrated into electric powertrains, and their interaction must be analysed. The test benches therefore need to be adapted quickly and flexibly according to the respective requirements of the testing tasks. CSM says the HV BM C variants simplify that necessary conversion work.

In addition, they simplify the coupling of different test bench set-ups. Using the HV BM 1.2C, an electric powertrain can easily be reconnected to a battery simulator, a high-voltage battery or a fuel cell.

Adding other components to the test set-up is also simplified. If, for example, a PTC heater or a braking resistor is to be added in addition to an electric powertrain, the components can be plugged into the HV BM C variants. On electric motor or powertrain test benches, the HV BM 3.3C makes it easy to change DUTs such as inverters and electric motors via the PowerLok connectors.

Using the HV BMs as a part of the company’s Vector CSM E-Mobility Measurement System, the necessary measurements and power analyses for the efficiency of individual components or the complete powertrain can be performed in real time. This larger system allows a range of test tasks to be easily implemented, and the measurement set-up can be easily expanded with additional measurement modules for acquiring other physical variables or data from control units.

ONLINE PARTNERS