Cotes cuts carbon footprint of running dry rooms

(Images courtesy of Cotes)

Drying rooms are critical to lithium-ion battery manufacture to ensure that the electrodes are prevented from absorbing moisture, which can lead to a reduction in lifespan and even catastrophic failure (writes Peter Donaldson).

Running these dry rooms typically takes a lot of energy, mostly to provide hot air. However, Danish company Cotes has developed a much more efficient way it calls Exergic Technology to do this that significantly reduces the battery’s overall carbon footprint.

Understanding humidity is key to getting rid of unwanted moisture from air, and warm air holds more water than cold air.

Absolute humidity is the amount of water vapour in a given mass of air, and is typically expressed in grams per kilo. Relative humidity, meanwhile, is the amount of water in the air expressed as a percentage of the maximum it can hold at a given temperature. When that percentage exceeds 100, the water begins to condense out.

The temperature at which that happens is called the dew point, which varies with absolute humidity, so the lower the dew point temperature the drier the air.

A dew point as low as -70 C is needed to dry the air in the electrode processing rooms sufficiently, which means the air must be passed through a de-humidifying rotor system. This needs two airstreams, a cold one to dry the air that’s fed to the processing room and a heated one to remove the moisture from the rotor itself, in a process called regeneration.

In conventional processes, the regeneration air must be maintained at between 140 and 180 C if it is to remove enough water, a temperature range only available from gas or electric heaters. Combined with high-volume airflows, it is these temperatures that drive the high energy consumption of a typical dry room, Cotes’ co-owner and business development manager Thomas Ronnow says.

He adds that all systems recycle some of the air that has passed through the dry room to reduce the required energy consumption, but that air must be mixed with fresh air from outside. The air coming back from the dry rooms is very dry, but if mixed with humid air it has to be dried again, and this marginal drying is expensive.

“We make sure we don’t mix in air that is of lower quality than the return air, we do it in a way that reduces airflow, and our multi-stage process allows for lower temperature regeneration. We can go with 80 or 90 C, and that allows a lot of different sources of energy,” he says.

“It could be waste heat from the drying process, solar panels or a CO2 heat pump. We can also go down to a dew point of -120 C, which means we have a lot of extra safety in our process.”

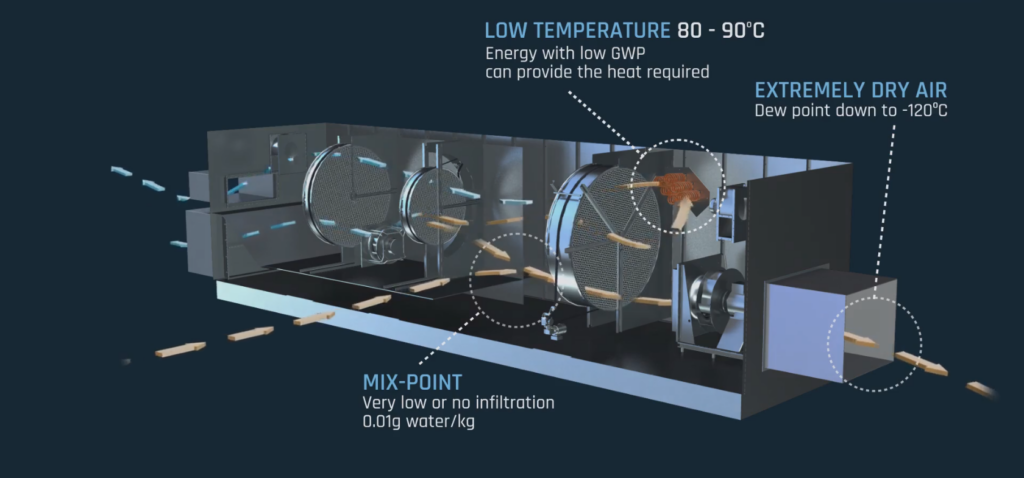

A typical Exergic Technology air drying system has a fresh air inlet leading to a pre-cooler to encourage moisture to condense onto porous silica gel that coats the de-humidifier rotor in the first-stage humidity removing section.

Downstream of this rotor, a recirculation air inlet re-admits air from the dry room into a mixing chamber, where it meets fresh, dried air. The mixed air than passes through another cooler on its way to the larger, second-stage rotor, which it cools along the way, before being fed into the dry room.

Some of that airflow is not sent to the dry room but is instead used to ‘regenerate’ the de-humidifier rotor by removing the water from it. Each rotor is divided into diametrically opposed cold and hot sections that respectively remove and relinquish water from the air.

The regeneration air flows out of the second-stage rotor, into a heater and back into the rotor, where it picks up moisture from it by evaporation. This air then passes through a second heater and then back through the hot section of the first-stage rotor before finally leaving the system. Most Exergic systems also have a third stage for extra efficiency, but the principle is the same.

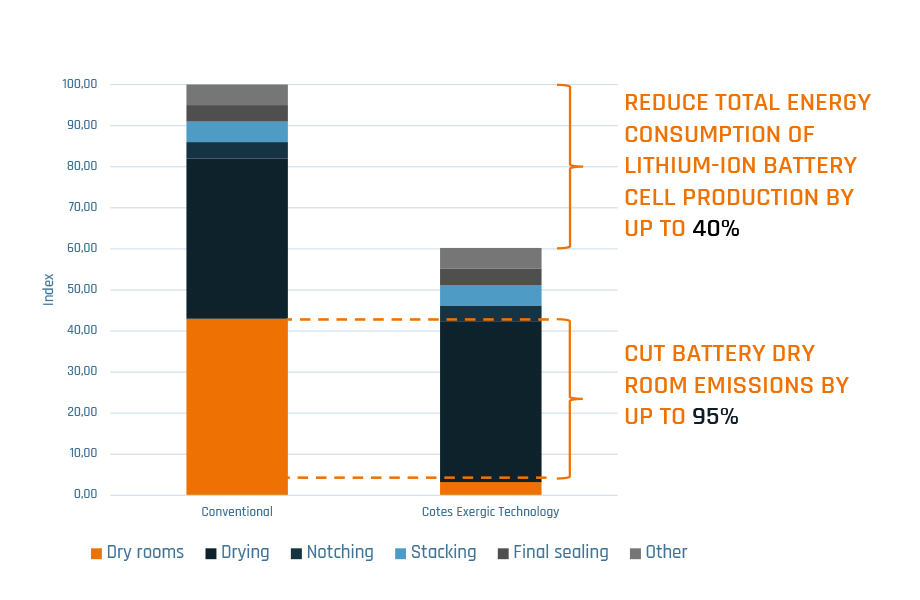

“If you look at the overall emissions to make a lithium battery, including mining the metal and so on, then 19% is for cell manufacture, Ronnow says. “And of that 19%, 43% is for running the dry room. That means about 8% of the total carbon emissions from the battery is from running dry rooms, and we can cut that by up to 95%. So we can reduce the embedded carbon in the battery by up to 7.7%.”

ONLINE PARTNERS